Alzrtin composite multi-gradient multi-coating turning insert and preparation method thereof

A multi-coating and multi-gradient technology, which is applied to turning equipment, coatings, and cutting tools for lathes, can solve the problems of large performance differences between coatings and tool substrates, low interface bonding strength, and large residual stresses in coatings, etc. problems, to achieve high bonding strength, reduce internal stress, and reduce repeated positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

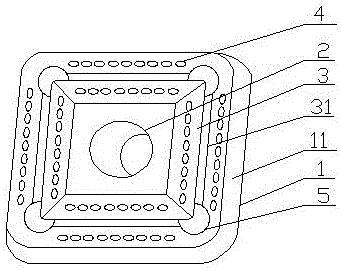

Image

Examples

Embodiment 1

[0025] The preparation method of AlZrTiN composite multi-gradient multi-coating turning blade: firstly clean the blade substrate, and then put the blade substrate and the required target into the vacuum chamber of the coating machine for coating. The coating process steps are as follows:

[0026] (1), Ti connection layer coating stage: After the vacuum chamber is evacuated, Ar gas is introduced to make the partial pressure of Ar gas in the vacuum chamber 0.4Pa, the bias voltage at both ends of the blade substrate is adjusted to 100V, and then the Ti target current is turned on and Keep it at 15A, and the coating time is 3.5min;

[0027] (2), TiN gradient transition layer coating stage: pass N into the vacuum chamber 2 , and adjust the amount of Ar gas to make N 2 The partial pressure ratio with Ar gas is 1.5:1, the air pressure in the vacuum chamber is 0.4Pa, the bias voltage at both ends of the blade substrate is adjusted to 100V, then the Ti target current is turned on and ...

Embodiment 2

[0032] The preparation method of AlZrTiN composite multi-gradient multi-coating turning blade: firstly clean the blade substrate, and then put the blade substrate and the required target into the vacuum chamber of the coating machine for coating. The coating process steps are as follows:

[0033] (1), Ti connection layer coating stage: After the vacuum chamber is evacuated, Ar gas is introduced to make the partial pressure of Ar gas in the vacuum chamber 0.6Pa, the bias voltage at both ends of the blade substrate is adjusted to 250V, and then the Ti target current is turned on and Keep it at 15A, and the coating time is 4.5min;

[0034] (2), TiN gradient transition layer coating stage: pass N into the vacuum chamber 2 , and adjust the amount of Ar gas to make N 2 The partial pressure ratio with Ar gas is 1.5:1, the air pressure in the vacuum chamber is 0.6Pa, the bias voltage at both ends of the blade substrate is adjusted to 100V, then the Ti target current is turned on and ...

Embodiment 3

[0039] The preparation method of AlZrTiN composite multi-gradient multi-coating turning blade: firstly clean the blade substrate, and then put the blade substrate and the required target into the vacuum chamber of the coating machine for coating. The coating process steps are as follows:

[0040] (1), Ti connection layer coating stage: After the vacuum chamber is evacuated, Ar gas is introduced to make the partial pressure of Ar gas in the vacuum chamber 0.5Pa, the bias voltage at both ends of the blade substrate is adjusted to 200V, and then the Ti target current is turned on and Keep it at 15A, and the coating time is 4min;

[0041] (2), TiN gradient transition layer coating stage: pass N into the vacuum chamber 2 , and adjust the amount of Ar gas to make N 2 The partial pressure ratio with Ar gas is 1.5:1, the air pressure in the vacuum chamber is 0.5Pa, the bias voltage at both ends of the blade substrate is adjusted to 100V, then the Ti target current is turned on and ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com