Static contact angle calculation method

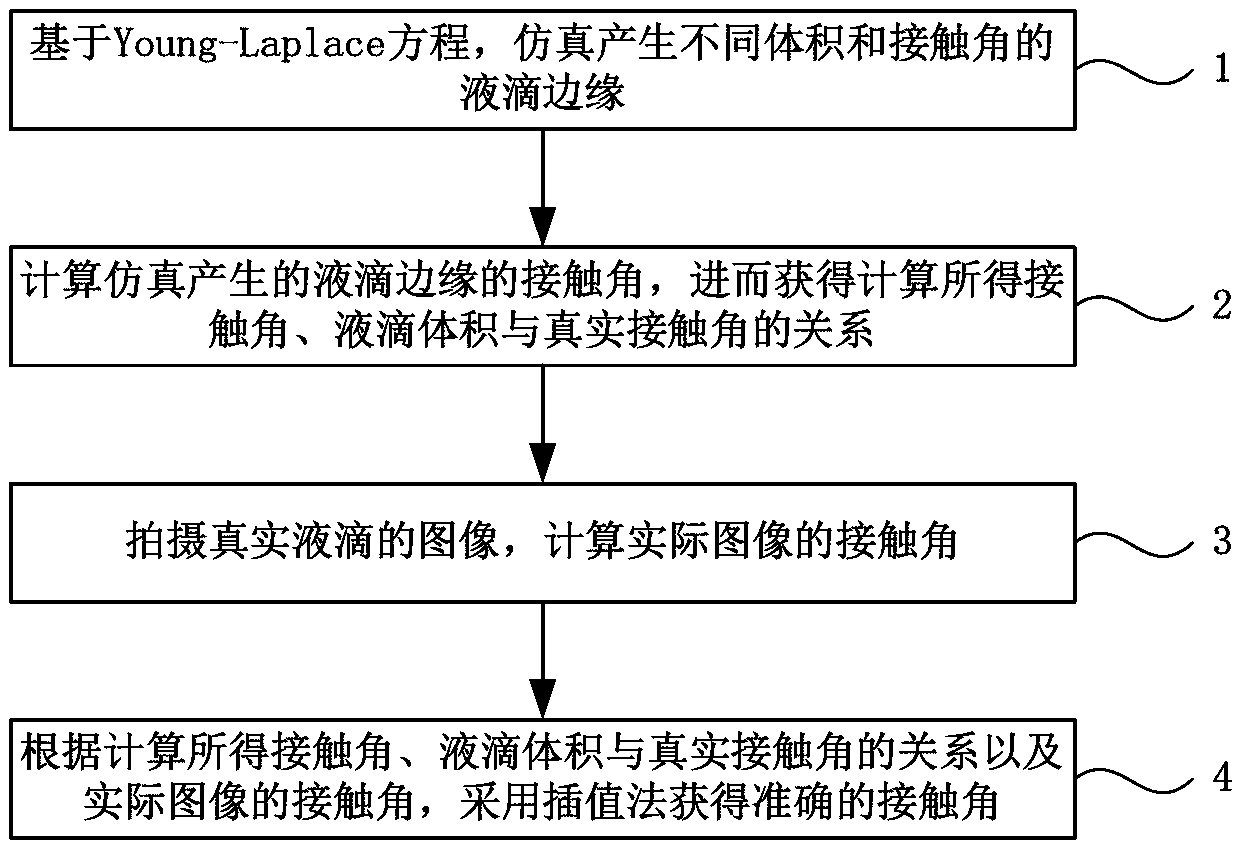

A technology of static contact angle and calculation method, which is applied in measuring devices, instruments, scientific instruments, etc., can solve the problem of inability to calculate static contact angle, and achieves the effect of less programming difficulty, short time-consuming, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

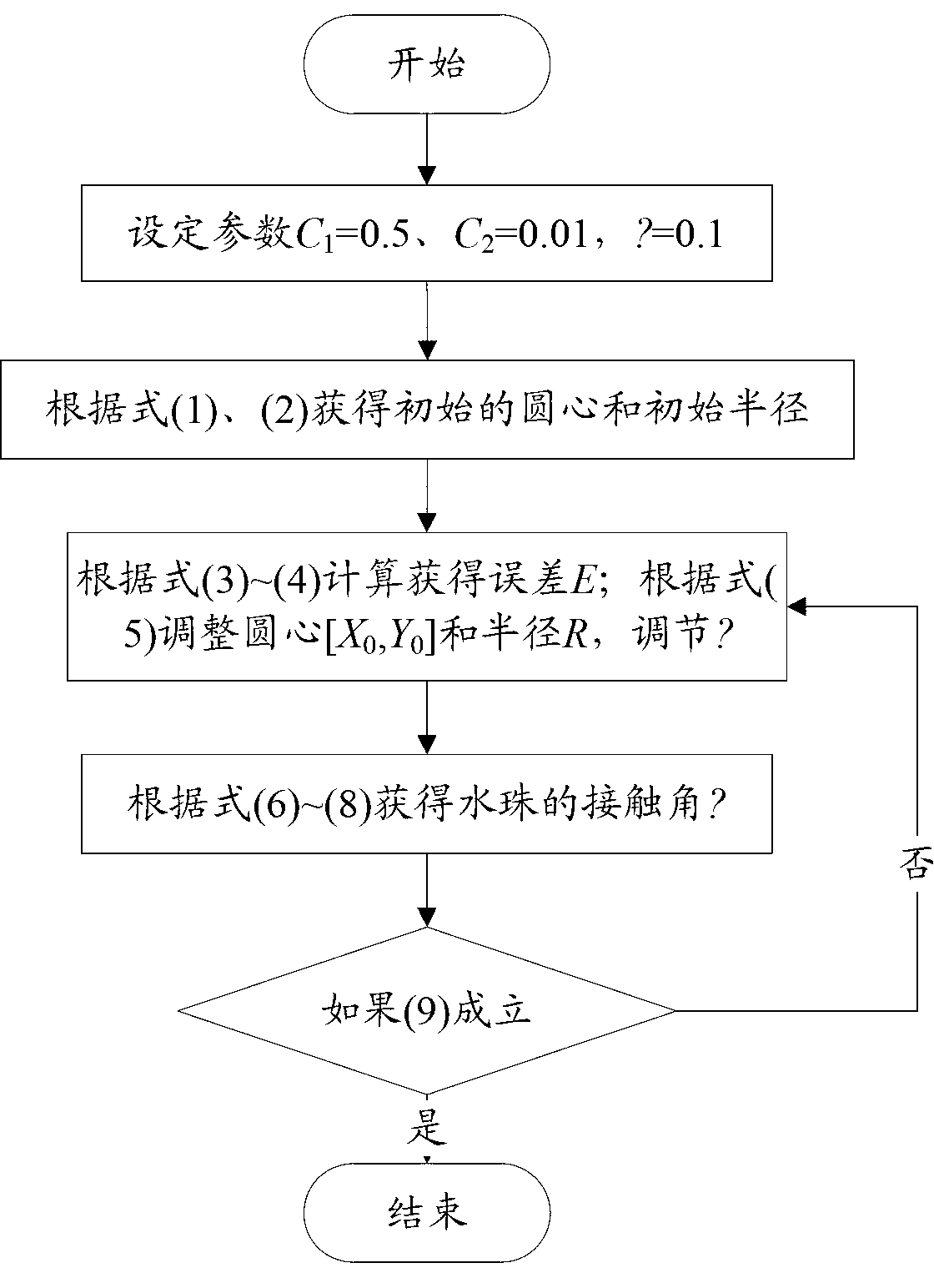

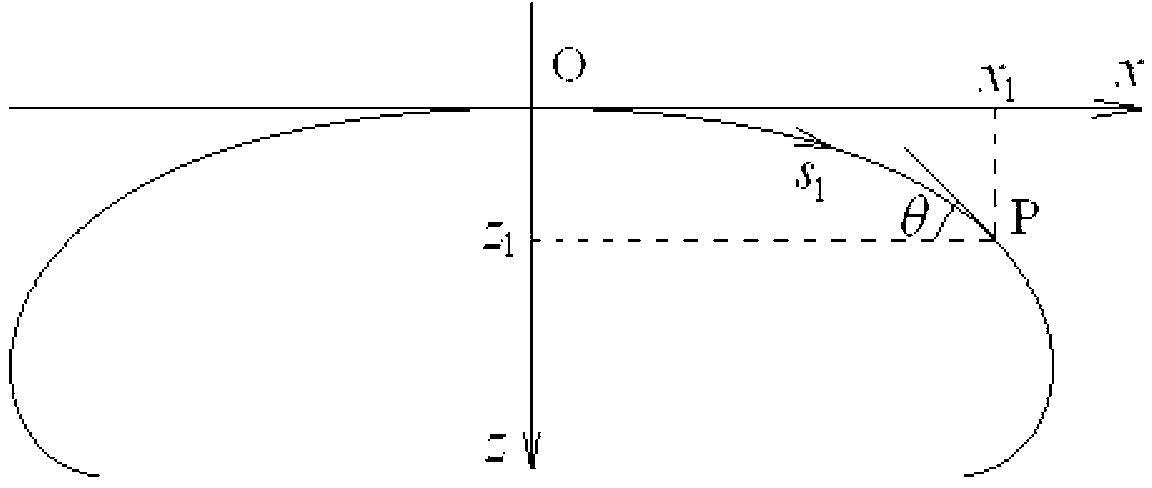

Method used

Image

Examples

Embodiment 1

[0106] In order to make the experimental results more convincing, the static contact angles were selected as 7°, 108° and 177° which had not been calculated, and the volume of water droplets was also different from the calculated case. The calculated results of the original circle fitting method and the revised circle fitting method proposed by the present invention are as attached Figure 9 shown.

[0107] attached by Figure 9 It can be seen that when the original circle fitting method is used, the algorithm error gradually increases with the increase of the volume of the water droplet, and the volume of the water droplet is less than 1000 μL and the length of the contact line is not greater than 2 cm. When the actual contact angles are 7°, 108° and 177° °, the maximum errors of the original circle fitting method were -3.52°, -64.54° and -115.66° respectively. After adopting the algorithm of the present invention to amend, even if the calculation result of the volume incre...

Embodiment 2

[0109] Drop 5, 10, 20, 50, 100, 200, 500, and 1000 μL of deionized water on the silicone rubber sample, respectively. The calculation result of the circle fitting method and the circle fitting method calculation result of the correction proposed by the present invention are as attached Figure 10 shown. The edges and contact angles obtained by the circle fitting method of the real water drop images when the water drop volumes are 5 and 100 μL are shown in the attached Figure 11 shown.

[0110] attached by Figure 10 It can be seen that for the real water drop image, the error of the circle fitting method gradually increases with the increase of the volume of the water drop. Figure 7 The simulation results of b are in good agreement. The contact angle calculated by the modified circle fitting method proposed by the present invention under different water drop volumes all changes around 109°, with a maximum deviation of 4.14° and a standard deviation of 2.63°. Obviously, ...

Embodiment 3

[0112] There is a super-hydrophobic sample, and about 9 μL of deionized water is dropped on it. The calculation results of the obtained image using the circle fitting method and the ADSA-P method are shown in the attached Figure 12 shown.

[0113] attached by Figure 12 It can be seen that when the static contact angle is very large, although the volume of the water drop is not too large, there is still a large error in the circle fitting method, and there is a significant gap between the obtained water drop edge and the real water drop edge, especially at the critical triple line Nearby, the follow-up analysis shows that its error is about -18.62°. The ADSA-P method can fit the edge of the water drop very well, and the obtained contact angle is 166.24°, the accuracy is guaranteed, and it can easily calculate the interfacial tension. But its principle is more complex, programming is difficult, and calculation time is longer, such as attached Figure 12 The calculation time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com