Method, device and system for monitoring high-speed electric multiple unit train bogie bearing faults

A high-speed EMU and fault monitoring technology, applied in mechanical bearing testing, railway vehicle testing, etc., can solve problems such as temperature data interference, midway parking, and affecting transportation order, so as to improve safety, timely reference, and timely monitoring results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

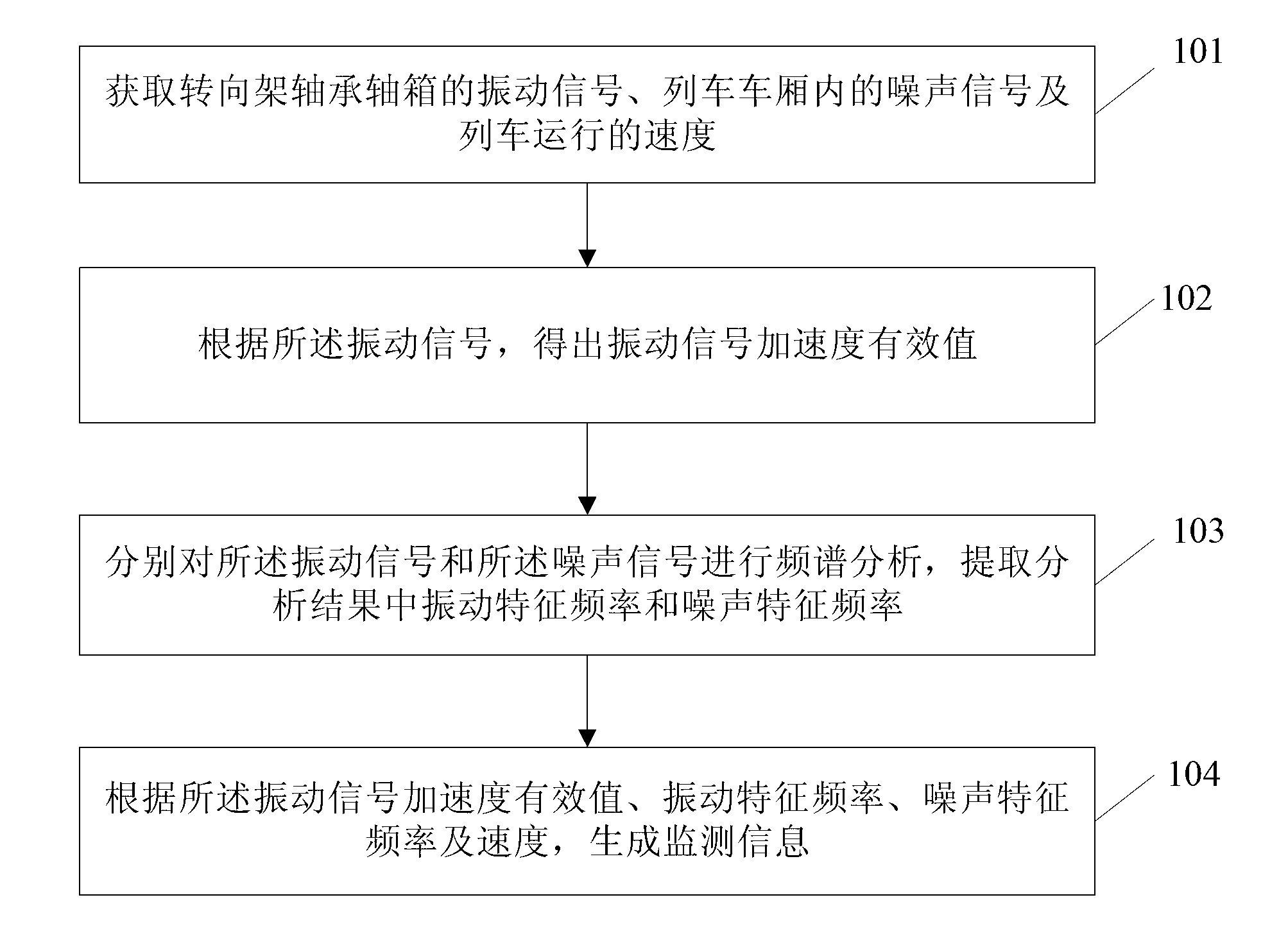

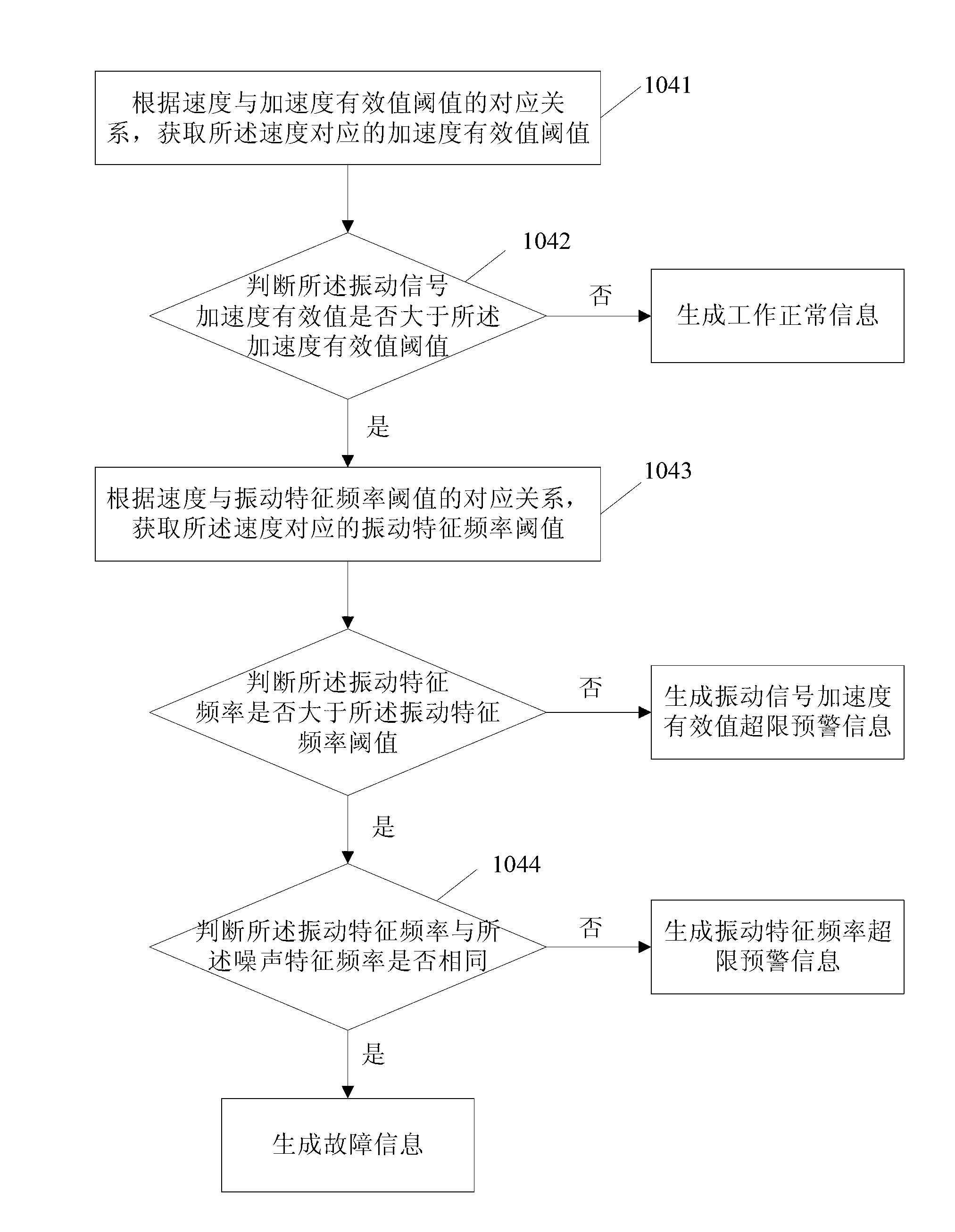

[0028] Such as figure 2 As shown, the schematic flow chart of Embodiment 1 of the method for monitoring the bogie bearing fault of a high-speed EMU train provided by the present invention. As shown in the figure, the method described in the first embodiment includes:

[0029] Step 101 , acquiring the vibration signal of the axle box of the bogie bearing, the noise signal in the train compartment and the running speed of the train.

[0030] Specifically, the high-speed EMU train bogie bearing fault monitoring device collects the vibration monitoring signals generated by the vibration monitoring sensors respectively arranged on the bogie bearing axle boxes and the noise monitoring signals generated by the decibel meters installed in the train compartments, Obtain the vibration signal and the noise signal. The high-speed EMU train bogie bearing failure monitoring device obtains the running speed of the train by receiving a speed signal sent by a speedometer installed on the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com