Wafer testing device

A technology for wafer testing and carrying wafers, which is applied in the direction of measuring devices, measuring device casings, measuring electronics, etc., and can solve problems such as uneven force, non-conforming depth of pin points, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

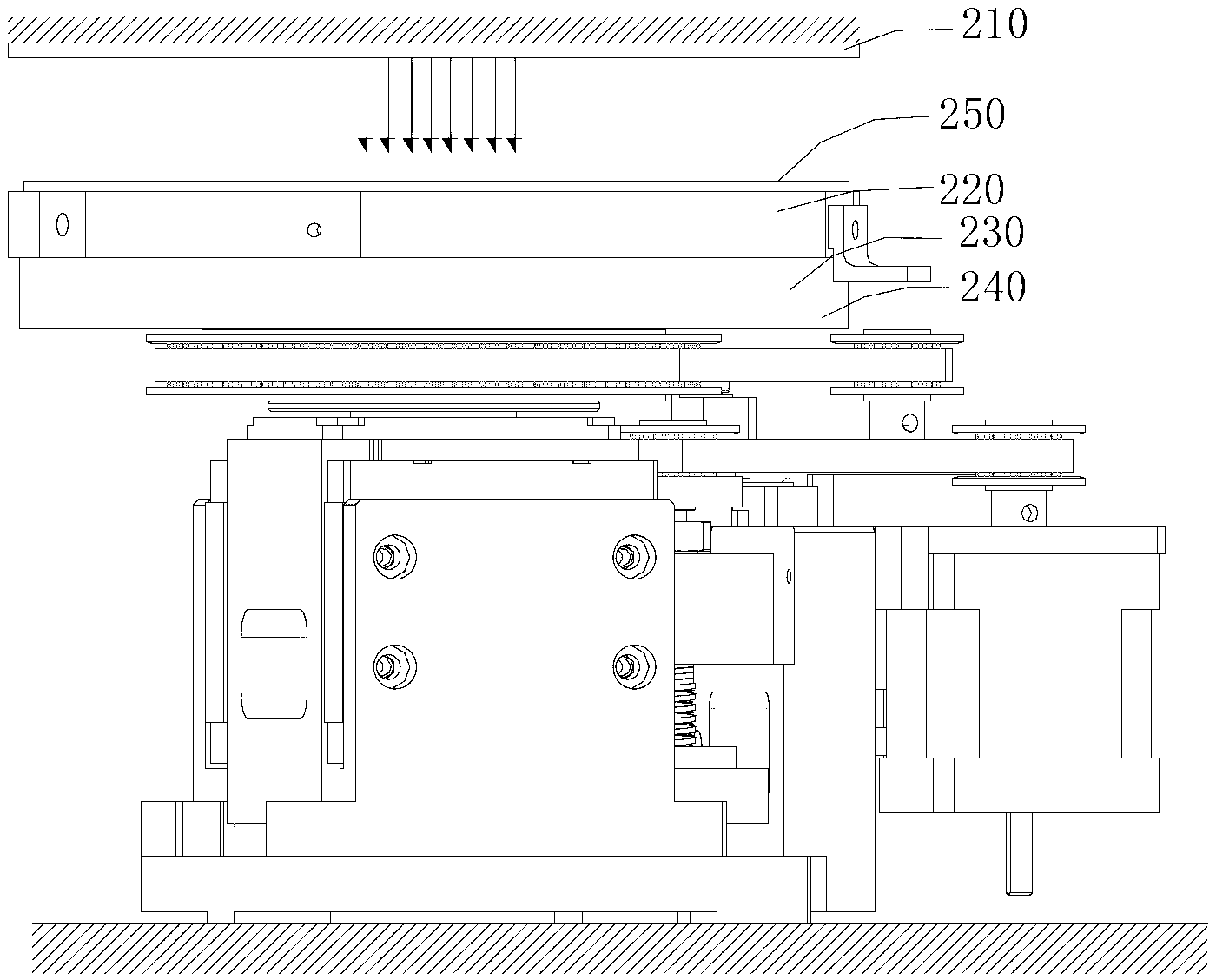

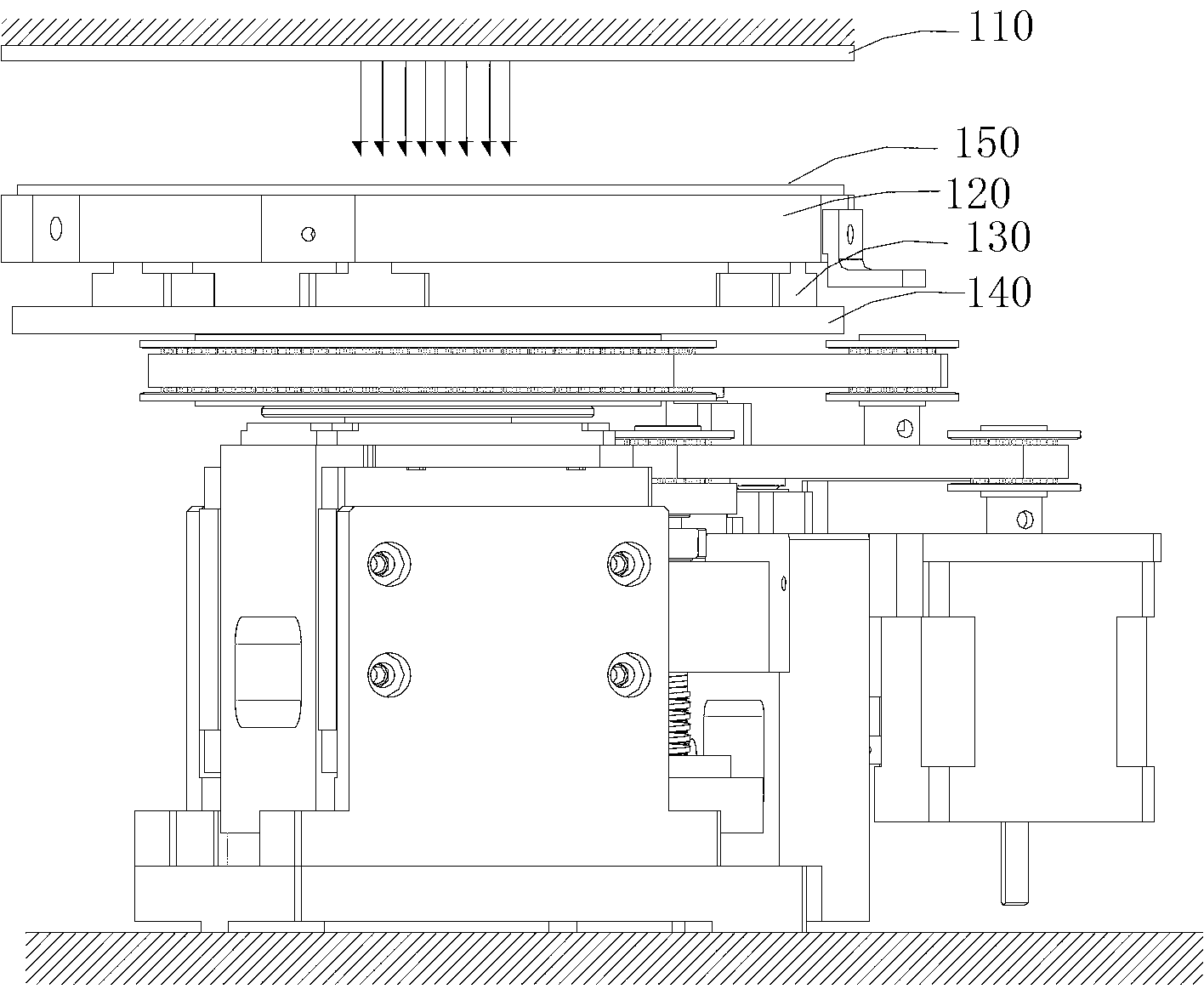

[0014] Please refer to figure 2 , an embodiment provides a wafer testing device. The wafer testing device includes a pin card 210 with a probe, a wafer stage 220 for carrying a wafer, a wafer stage fixing plate 230 for fixing the wafer stage 220, a fixing plate mounting plate 240 for fixing the wafer stage fixing plate 230, and A moving mechanism that drives the fixed plate mounting plate 240 to move. The wafer stage fixing plate 230 is an electrically insulating plate. The moving mechanism can drive the wafer stage 220 to move along the X, Y, and Z axes, so that the probes on the needle card 210 can contact the wafer 150 to test the wafer 150 .

[0015] The wafer testing device uses the wafer stage fixing plate 230 instead of the commonly used way of using three wafer stage fixing seats to support the wafer stage. Since the wafer stage fixing plate 230 is an electrically insulating plate, the stress on it will be relatively uniform. In this way, the wafer carrier 220 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com