Optimal control system for steel rolling heating furnace

An optimized control and heating furnace technology, applied in the general control system, control/regulation system, adaptive control, etc., can solve the problems of flue gas oxygen measurement lag, difficult optimal operation, and difficult to meet real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

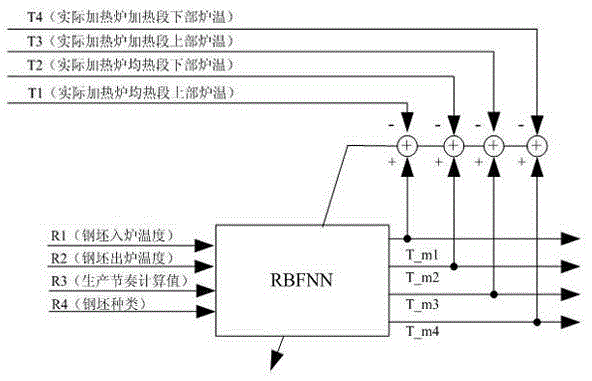

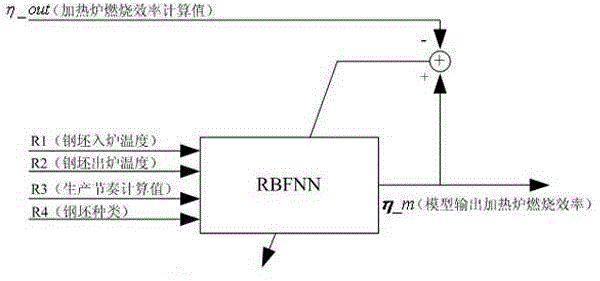

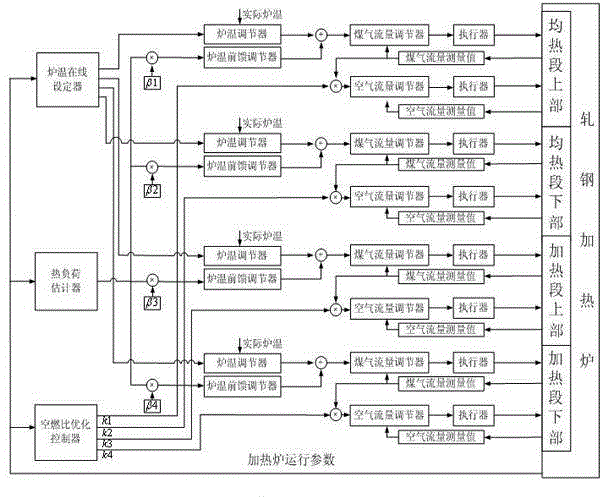

[0059] The system control block diagram is attached image 3 shown.

[0060] 1. Furnace temperature online setter

[0061] 1) Establish a production rhythm model

[0062] The production rhythm is the amount of steel tapped per unit time, and the unit is "root / hour" or "piece / hour". According to the measurement signal of the photoelectric switch used to detect the billet out of the furnace, the interval between two billets out of the furnace is calculated in real time, and the output of each billet is calculated. Hourly steel billet output R3;

[0063] R3=3600 / (t (k)-t (k-1))

[0064] t(k) is the moment when the power switch detects that a steel billet is out of the furnace, and t(k-1) is the time when the last steel billet was out of the furnace;

[0065] 2) billet type

[0066] According to the type of billet, a serial number is given at a time, such as 1, 2, 3, 4, ..., and the type of billet is used as a quantitative value. Among them, the selection of billet type req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com