Remote wireless monitoring method for thickener

A remote wireless, thickener technology, applied in electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the industrial production requirements that cannot meet the large data volume control of thickeners, and the difficulty of direct wiring connection of thickeners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The wireless monitoring method for the thickener provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

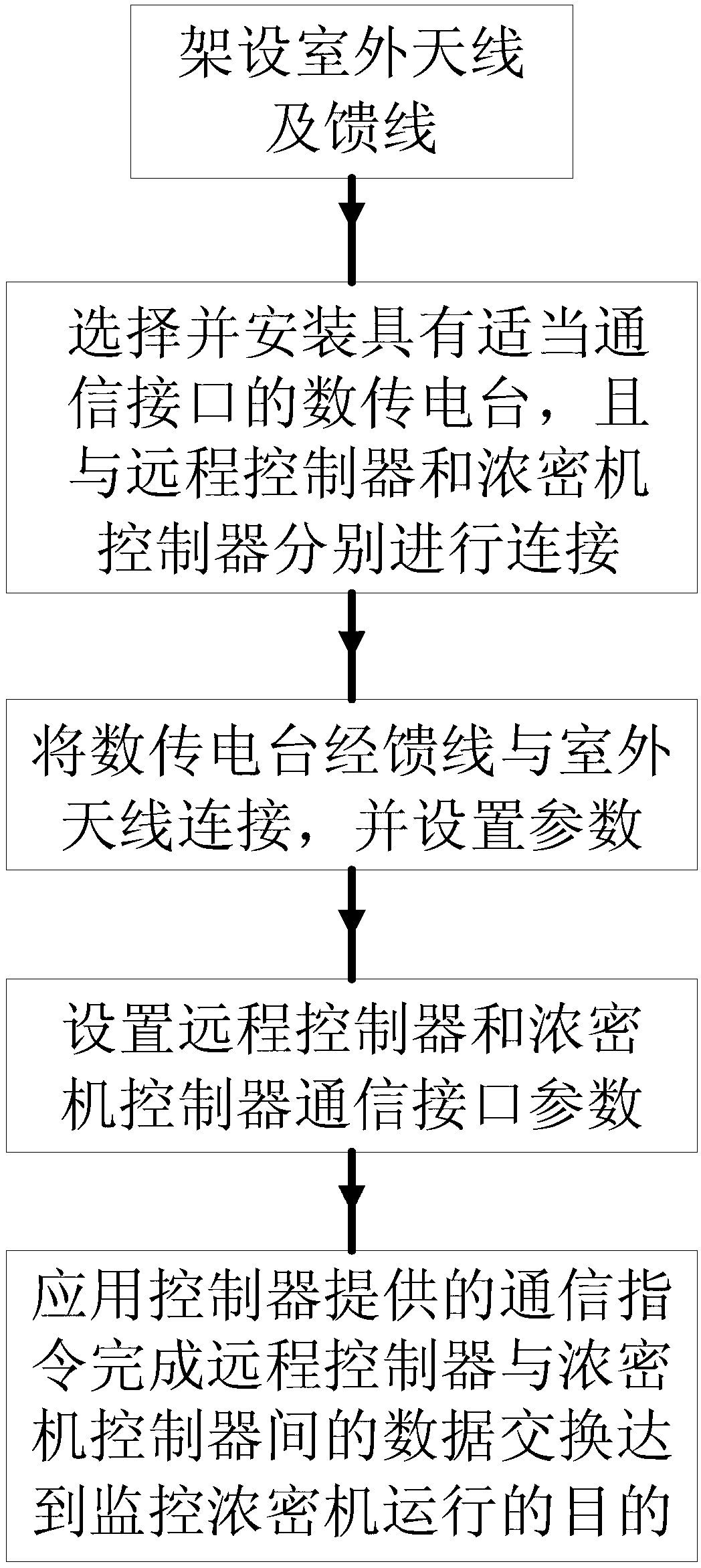

[0020] The implementation steps of the remote wireless monitoring method of the thickener are as follows: figure 1 As shown, it specifically includes the following steps:

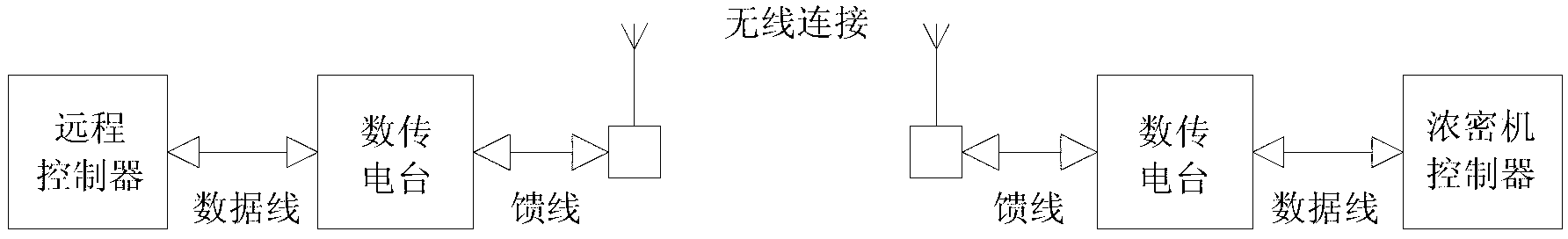

[0021] 1. Connect the device such as figure 2 , the outdoor antenna needs to be installed first, and the required height of the outdoor antenna must be calculated before installation. Since my country's radio management department has specially designated two frequency bands as dedicated frequency bands for wireless data transmission, they are 230MHz and 860MHz (currently most of the data transmission radio products in my country are distributed in the 230MHz frequency band), that is, they work in VHF ( VHF) and UHF (Ultra High Frequency) ultrashort wave bands. Ultrashort wave is mainly used for short-distance transmission. Unlike hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com