Simplified method for forecasting fatigue expansion service life of inclined crack in center of rectangular plate

A technology for crack fatigue growth and life prediction, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of conservative accuracy, complex crack analysis and calculation complexity, etc., and achieve the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

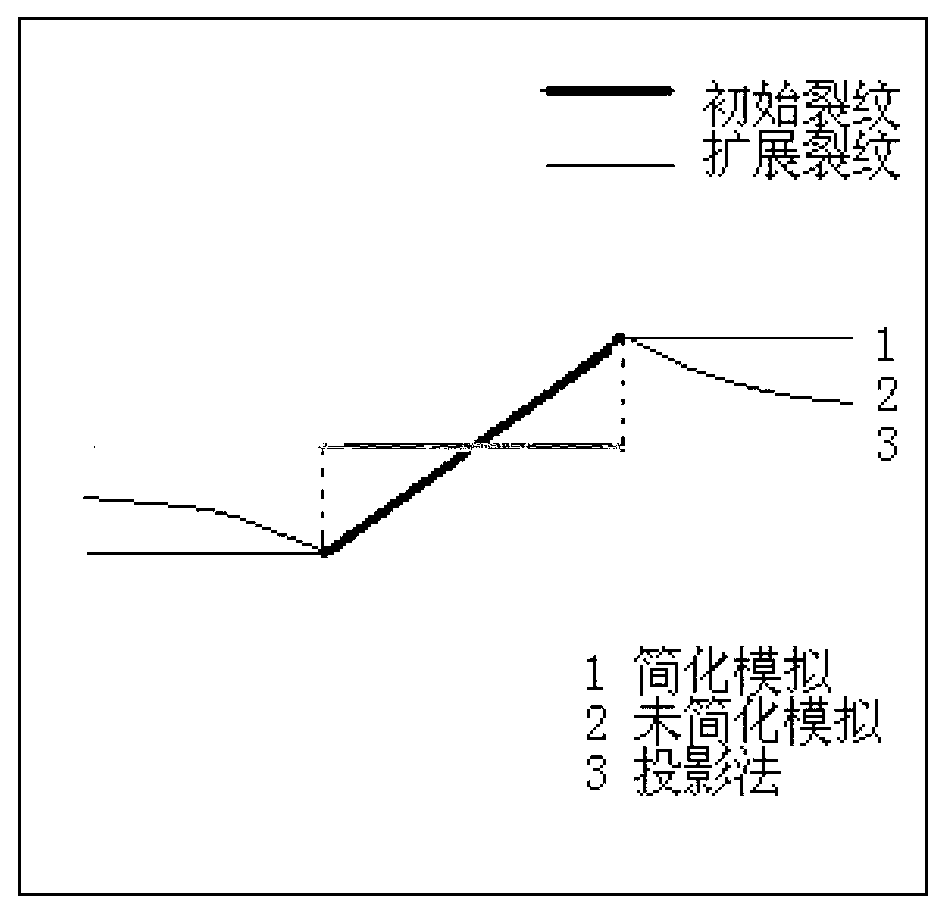

[0035] See Figure 4 , a simplified method for life prediction of oblique crack fatigue growth in the center of a rectangular plate of the present invention is realized by writing subroutines of each step in the Python language, and the specific steps of the method are as follows:

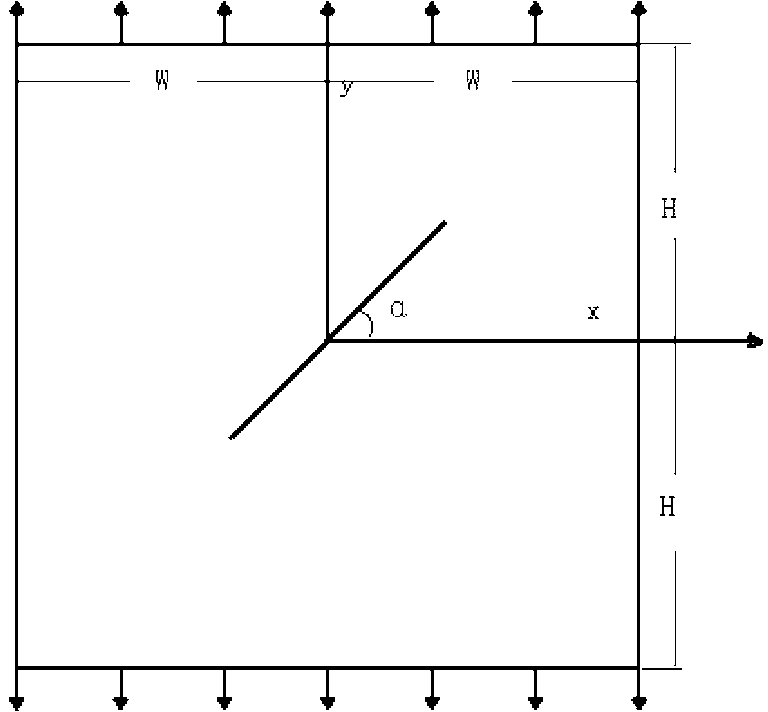

[0036] Step 1: Parametric modeling: Establish a finite element model of a rectangular plate with a central oblique crack. Such as figure 2 As shown, first call the create model subroutine to create a rectangular model with a width of 2W, a height of 2H, and the center at the origin of the coordinates; then call the define crack subroutine, define the length as 2a, and the angle b with the x-axis, at the center of the rectangular model crack, (first calculate the coordinates x of two points on the edge of the crack 1 = a cosb,y 1 =a sinb,x 2 =-a cosb,y 2 =-a sinb, connecting two points into a crack).

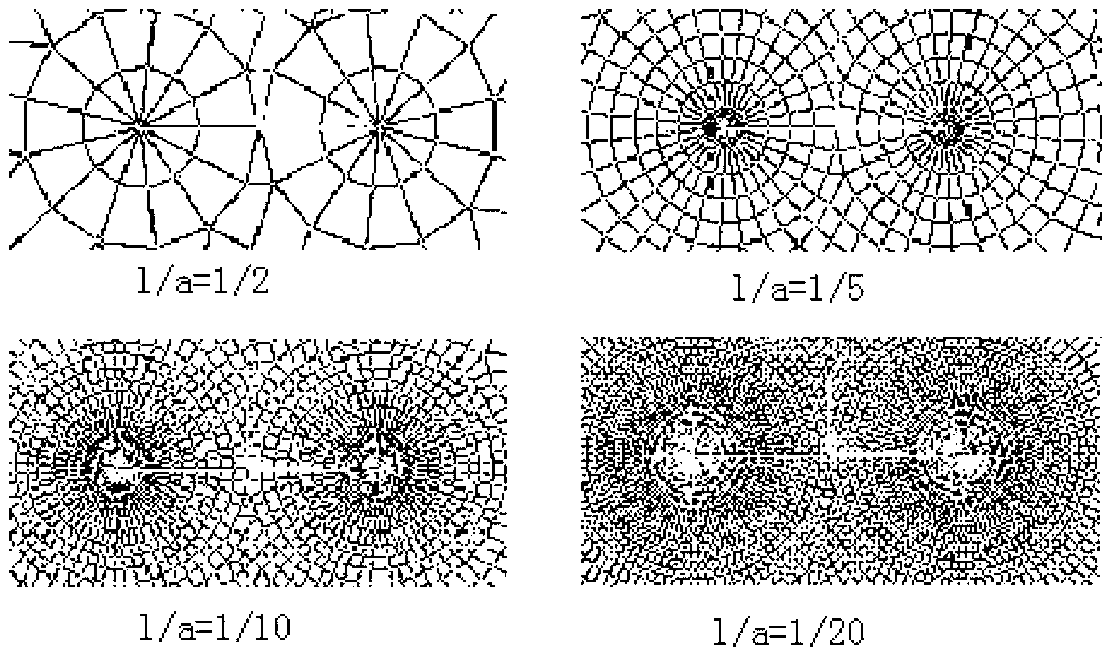

[0037] Step 2: Mesh division: Due to the existence of cracks, the grid near the crack tip ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com