An automatic simulation method of centrifugal pump cavitation performance based on CFD platform

A simulation method and centrifugal pump technology, applied in 3D modeling, instrumentation, design optimization/simulation, etc., can solve the problems of increasing research and development cycle and cost, waste of time, etc., to shorten the research and development cycle, reduce research and development costs, and improve simulation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the accompanying drawings.

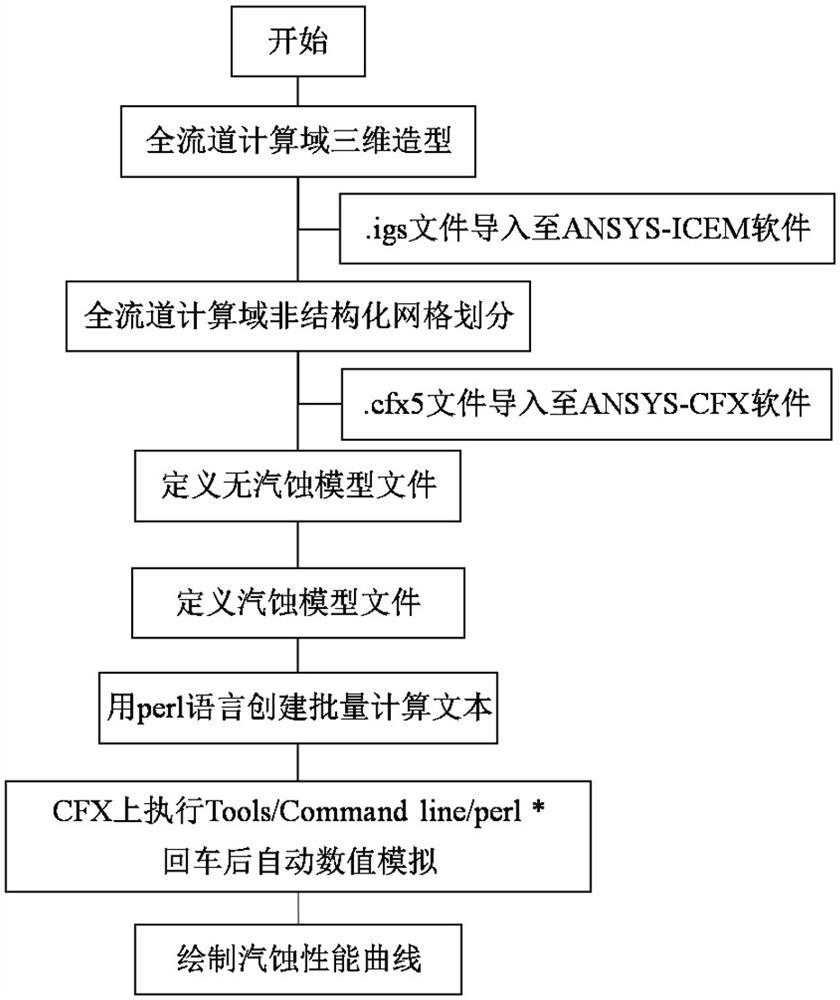

[0029] Such as figure 1 As shown, an automatic simulation method of centrifugal pump cavitation performance based on CFD platform includes the following steps:

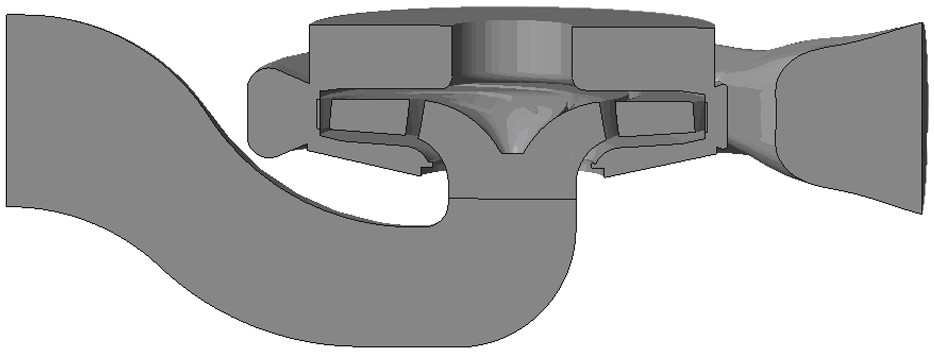

[0030] 1) Use CAD-CREO software to model the three-dimensional calculation domain of the entire channel of the centrifugal pump, and save the three-dimensional model of the calculation domain of the entire channel of the centrifugal pump as an *.igs file; figure 2 shown.

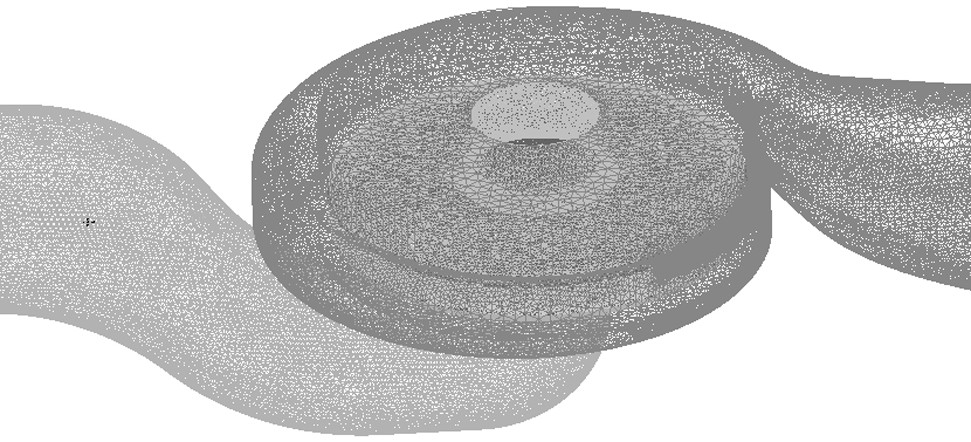

[0031] 2) Import the 3D model of the full channel computational domain of the centrifugal pump obtained in step 1) into the ICEM software, perform unstructured grid division of the full channel computational domain, and locally refine the grid in the complex calculation area, and The grid file of the full channel computational domain of the centrifugal pump is saved as a *.cfx5 file; for example image 3 shown.

[0032] 3) Import the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com