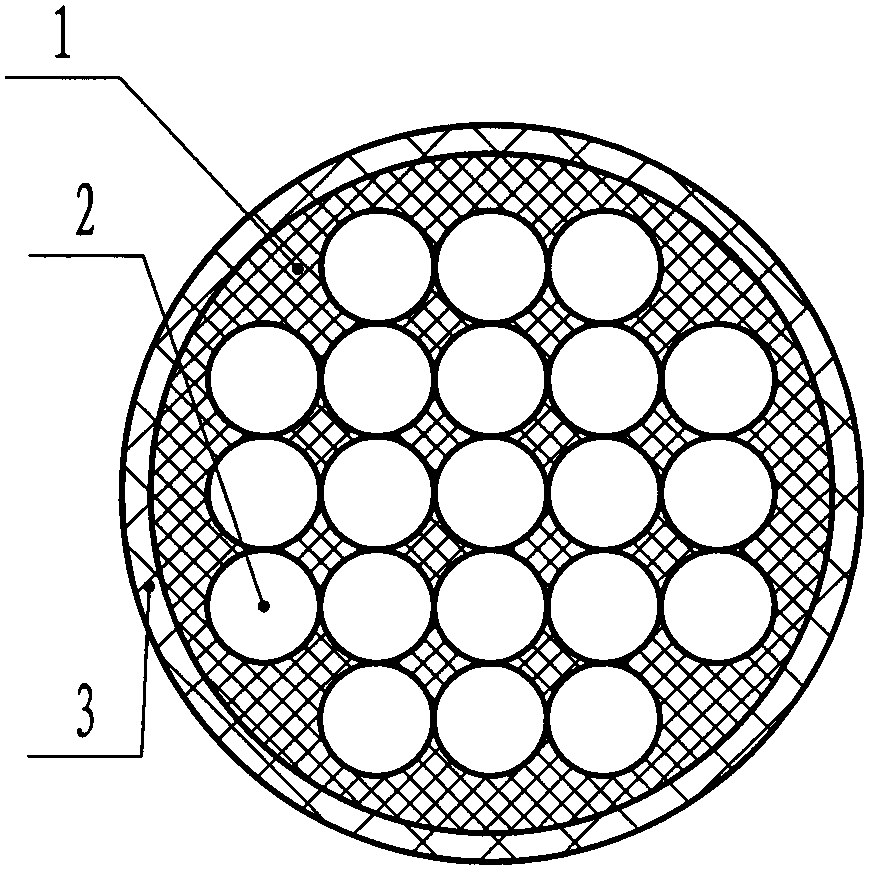

Large-diameter rod insulator mandrel

A technology of insulators and large diameters, applied in the direction of insulators, supporting insulators, electrical components, etc., can solve problems such as internal cracks, and achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

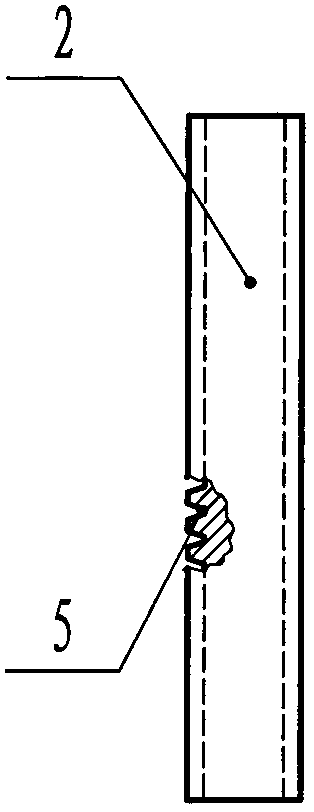

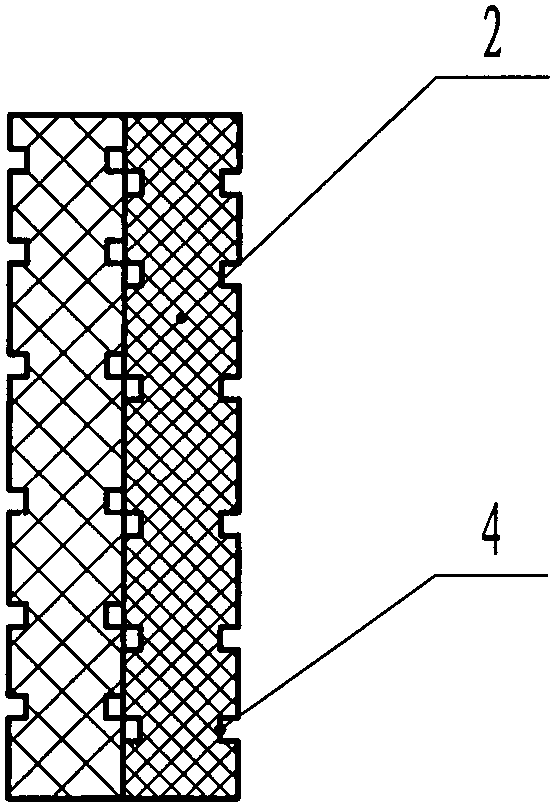

[0007] The structure and use of the present invention will be described in detail below in conjunction with the embodiments given in the accompanying drawings. Referring to the accompanying drawings, this kind of large-diameter rod-shaped insulator mandrel is characterized in that said mandrel (2) has an attached image 3 Annular groove (4) shown in . or have attached figure 2 the threaded groove (5) in the In order to make it suitable for the manufacturing needs of post insulators of different specifications and models, the mandrel is an epoxy resin rod. Or the so-called mandrel is a fiberglass epoxy resin rod. The size of the mandrel can be a combination of sizes.

[0008] For simple and convenient processing, the annular groove or thread groove on the mandrel is cut by lathe turning.

[0009] If mass-produced, the annular groove or threaded groove on the mandrel can be formed by mold casting or pouring.

[0010] In order to further increase the mutual bonding strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com