Groove-type compound parabolic concentrating power generation component

A compound parabola and power generation component technology, which is applied in photovoltaic power generation, electrical components, solar thermal power generation, etc., can solve the problems of low effective utilization of solar energy, large light dispersion at the light outlet, and small light concentration angle, etc., to shorten capital recovery The effect of increasing the concentration ratio and large concentration acceptance angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

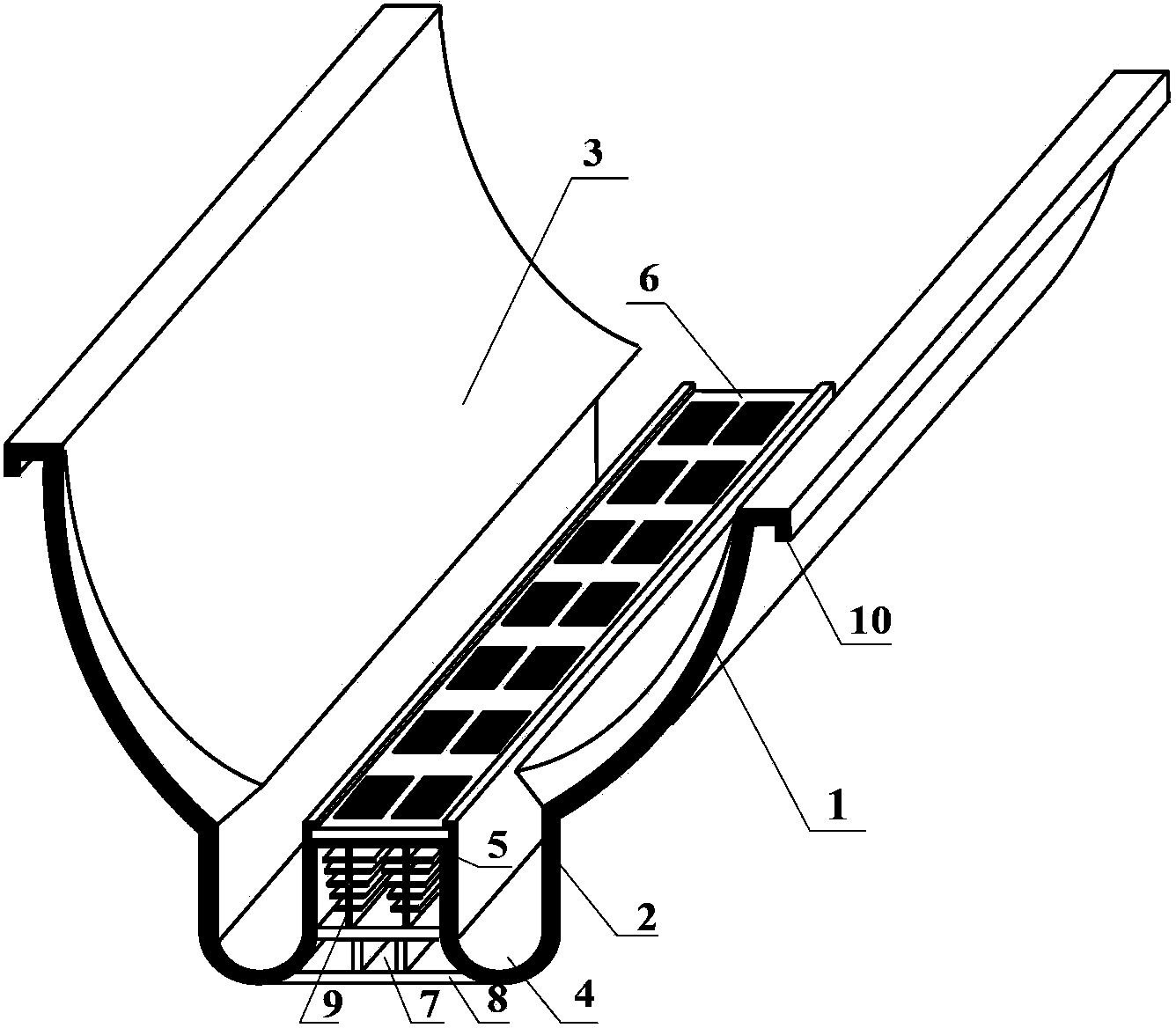

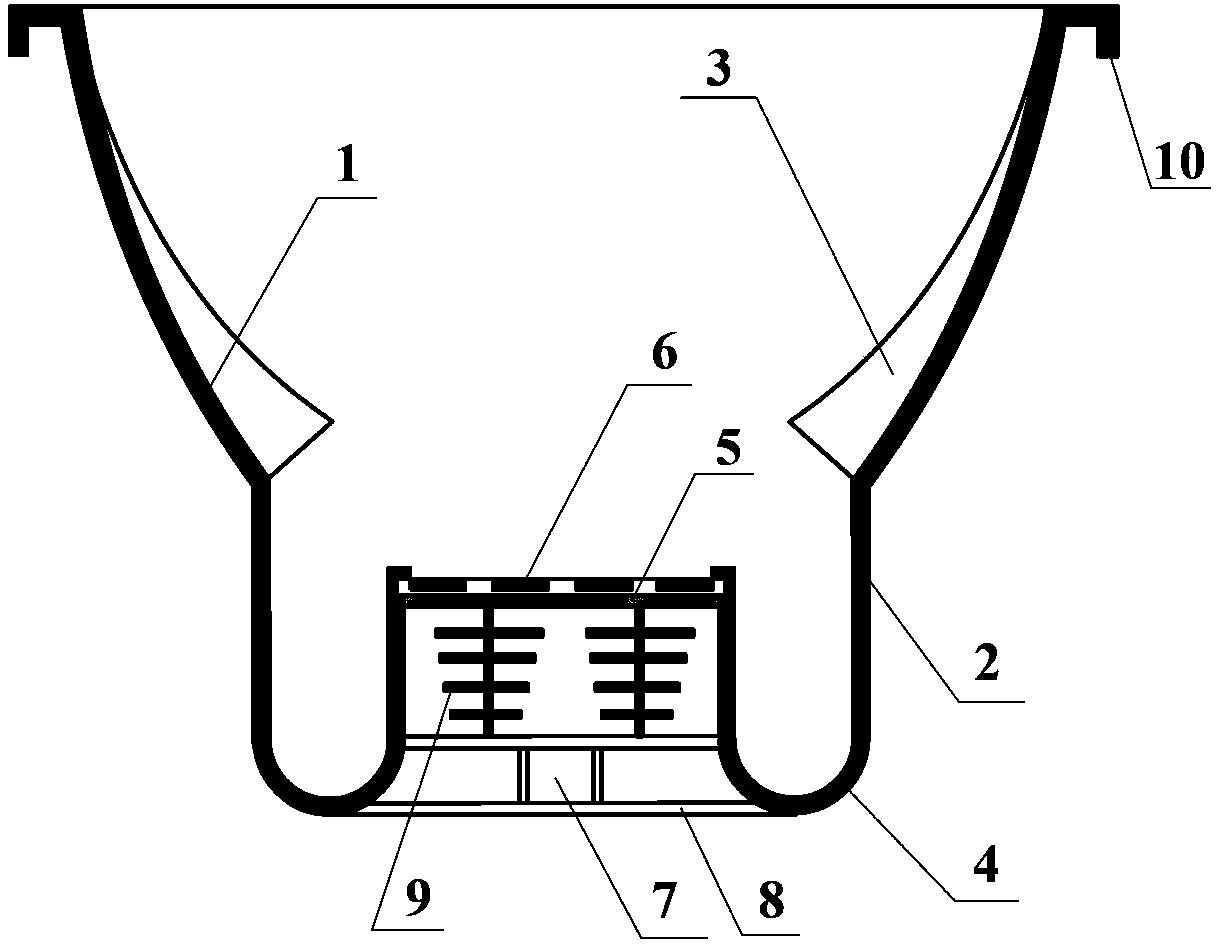

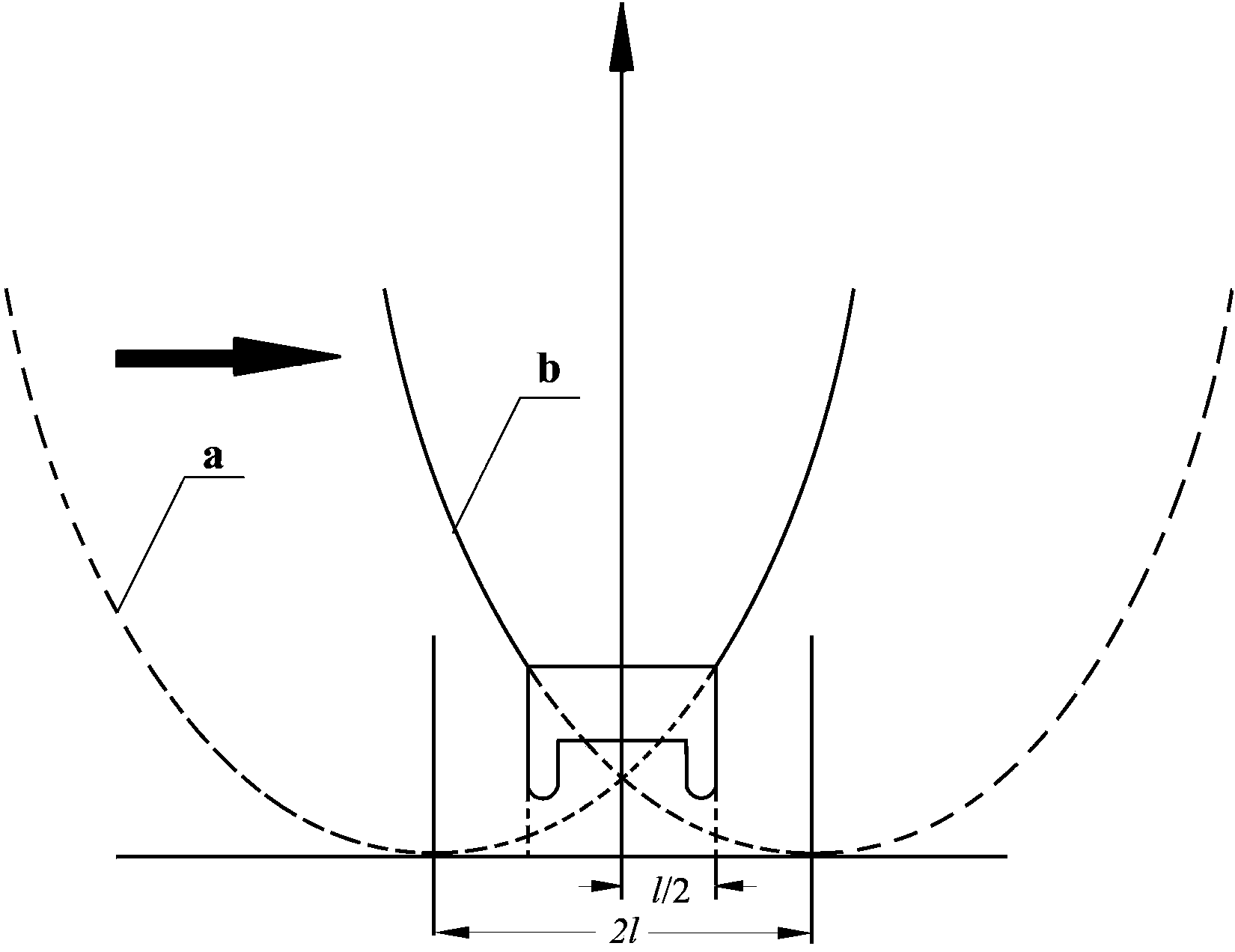

[0028] as attached figure 1 and 2 As shown, the present invention provides a trough-type compound parabolic concentrating power generation assembly, including a left concentrator, a right concentrator, a transparent total reflection film 3, a photovoltaic cell 6, a heat dissipation support plate 5, a fixed bottom plate 8 and heat dissipation ribs Sheet 9; wherein, the left concentrator and the right concentrator are centrosymmetric structures, the horizontal upper half of which is a paraboloid, and the top surface of the paraboloid extends outward horizontally to form a buckle 10 structure, and the horizontal lower half is a groove structure, The trough structure is a structure that extends vertically downward from the parabolic surface. The bottom of the trough structure forms a drainage groove 4. The inner surface of the parabolic surface is a parabolic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com