Wire replacing connecting plug

A plug and plug part technology, which is applied to devices, connections, contact parts, etc. to reduce the stress at the wire connection, can solve the problems of inconvenient replacement, increased replacement cost, power failure, etc., and achieves improved connection reliability and reduced failures. The effect of occurrence and reduction of failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

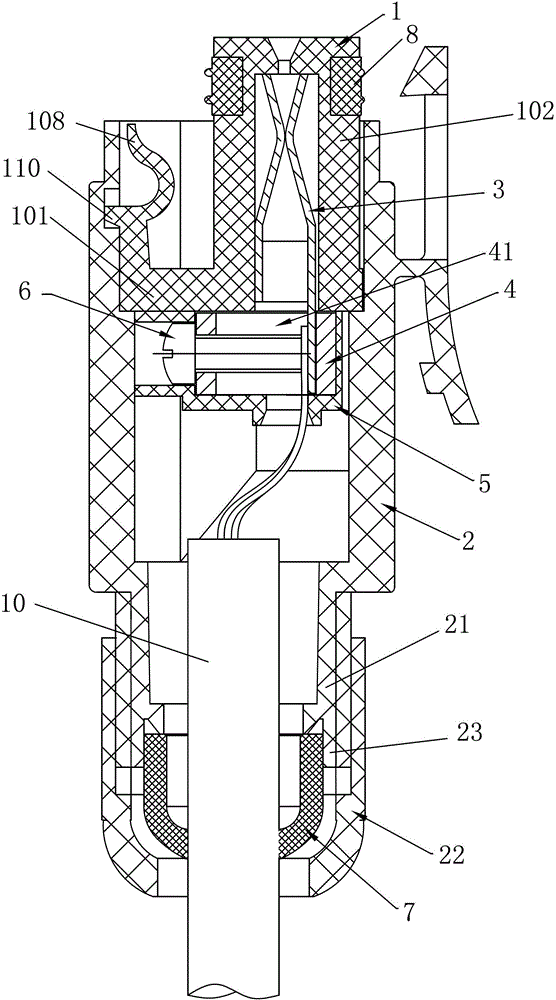

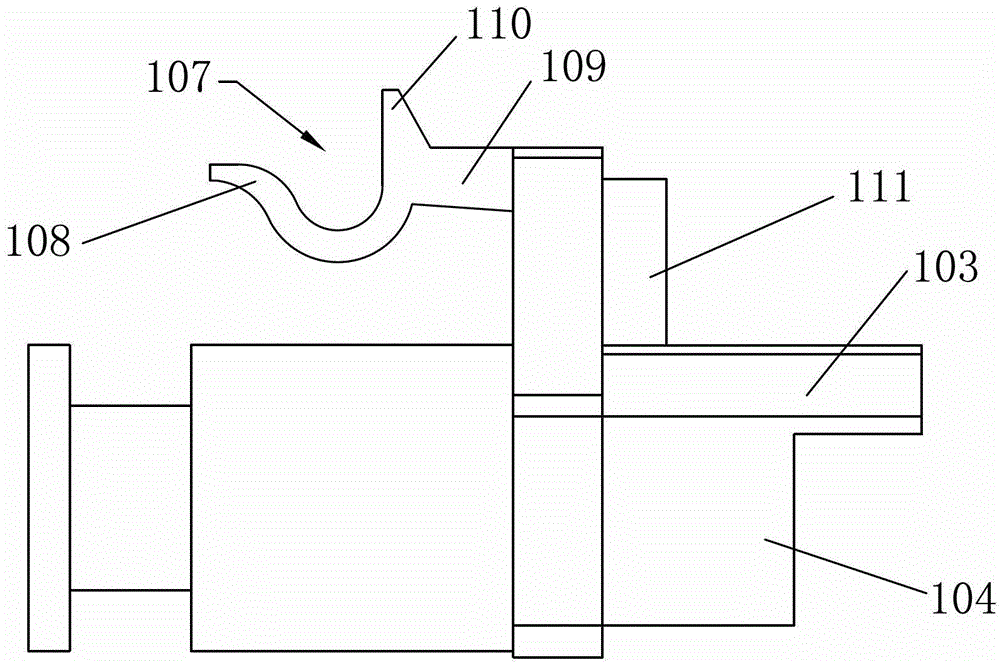

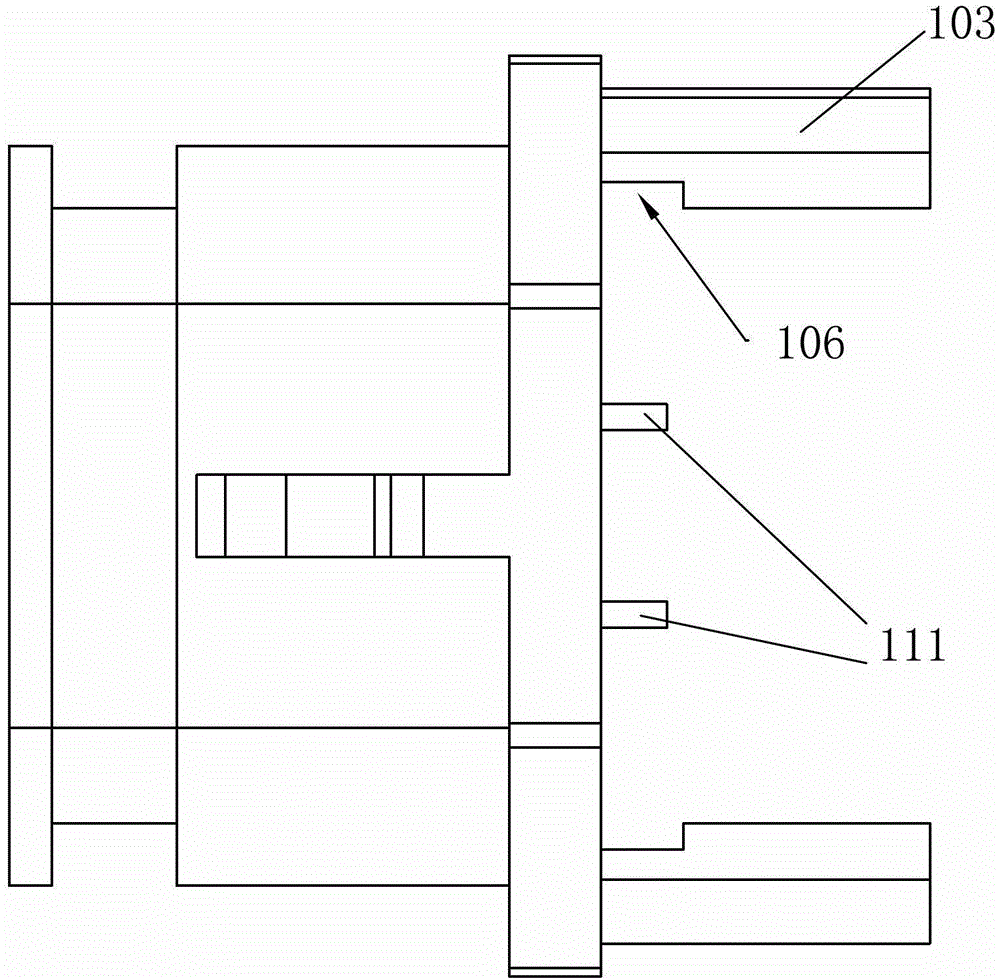

[0026] Embodiment: a kind of wiring plug for changing wires, Figure 1-Figure 10 As shown, it includes an insulating insert sleeve 1, a protective sleeve 2 matched with the insulating insert sleeve 1, an insert 3 inserted in the insert sleeve 1, and the outer end of the insert 3 extends outside the insert sleeve 1 and Inserted in the protective sheath 2, the protective sheath 2 has a wire channel for the wire 10 to pass through and be connected with the insertion piece.

[0027] The extension end of the insertion piece 3 is sleeved with a fixed block 4 with a connection cavity 41, the outer portion of the fixed block 4 is sleeved with an insulating sleeve 5, the protective sleeve 2 is sleeved on the periphery of the insulating sleeve 5, and the insulating sleeve 5 and the fixed block 4 are respectively provided with corresponding The locking piece goes through the hole, and the locking piece goes through the hole to fit the locking piece 6 (for easy operation, the locking piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com