Heat radiation structure and back board used by heat radiation structure

A technology of heat dissipation structure and heat dissipation bottom plate, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electric solid devices, etc. It can solve the problems of increasing the time for the assembler to assemble the heat dissipation module, difficult control of assembly force, and labor cost. , to achieve the effect of saving labor costs, easy disassembly and assembly, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the above-mentioned purpose, features and advantages of the present invention more obvious and easy to understand, according to the heat dissipation structure and the backplane used in the present invention, preferred embodiments are specifically cited below, and are described in detail as follows in conjunction with the attached related drawings .

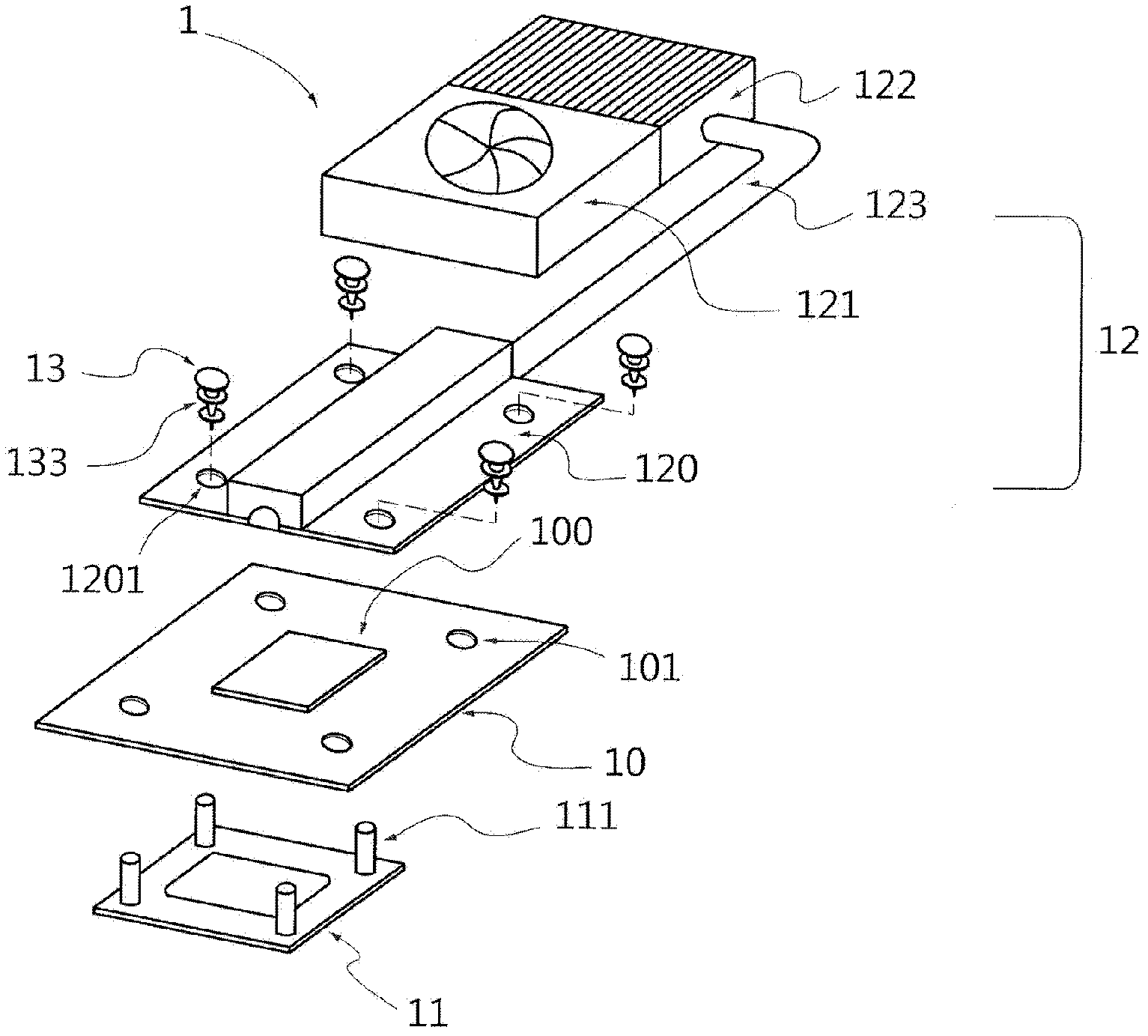

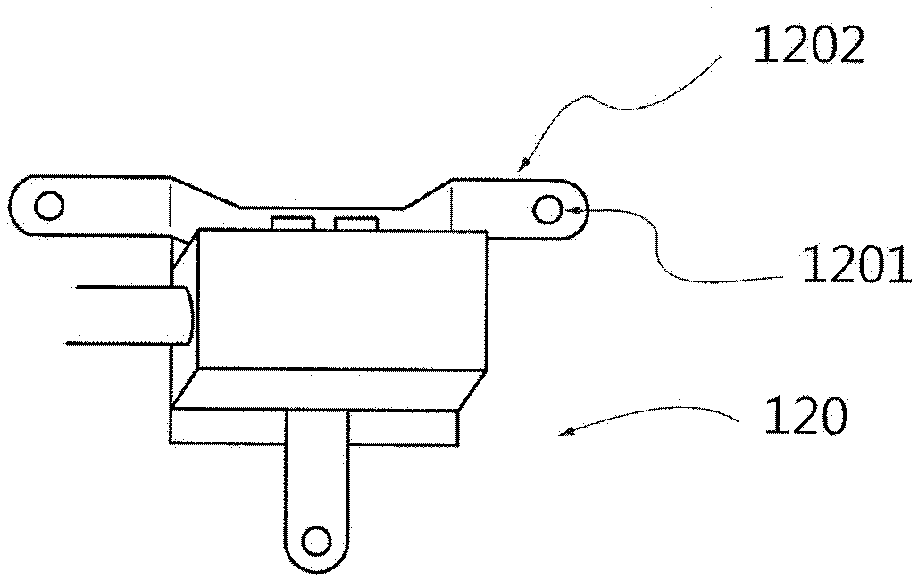

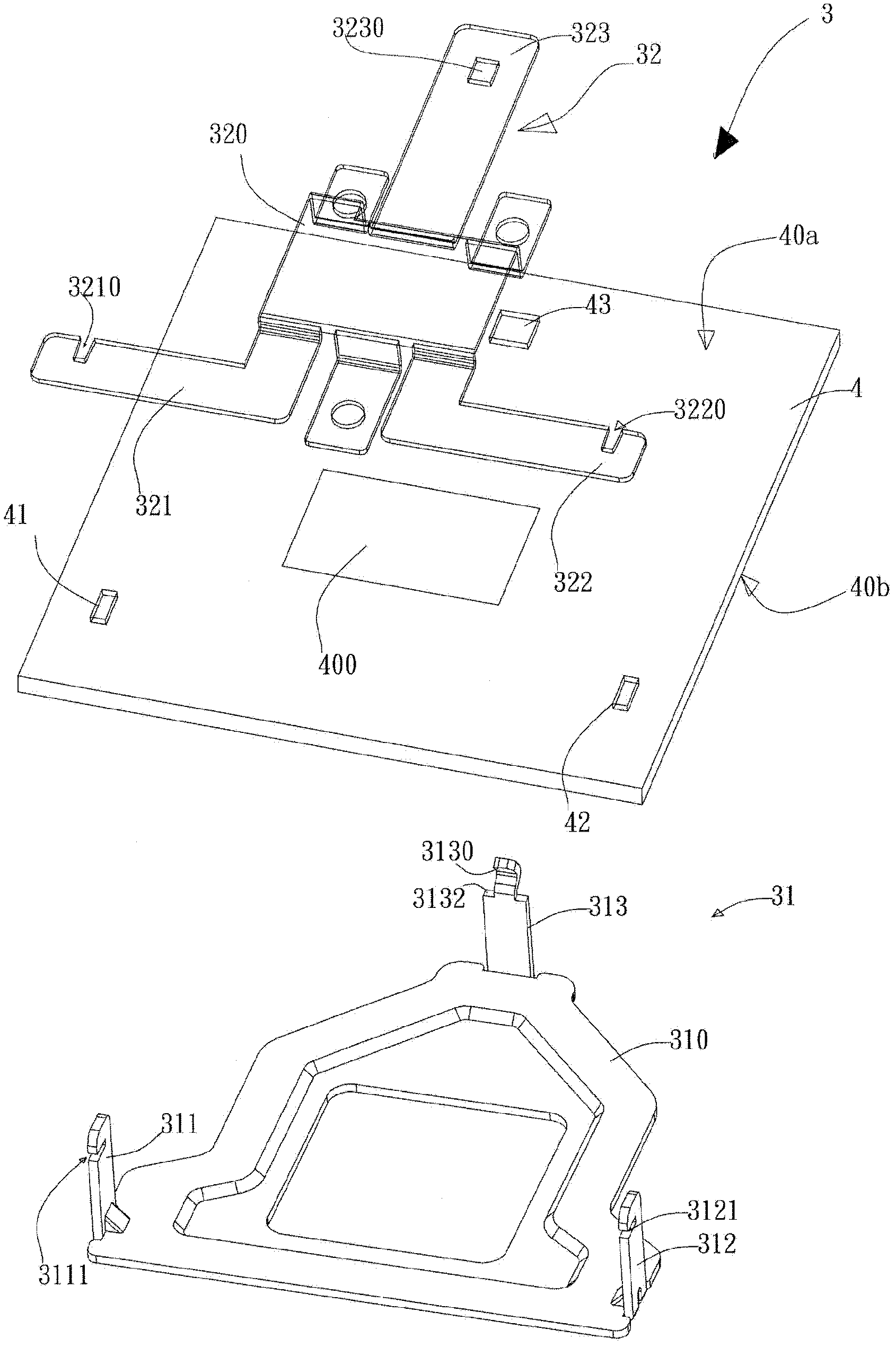

[0044] Please refer to Figure 3A , is the heat dissipation structure 3 of the embodiment of the present invention. The heat dissipation structure 3 is fixed on a circuit board 4 in an engaging manner, and is used to dissipate a chip 400 on the upper surface 40a of the circuit board 4. Around the chip 400, a first positioning hole 41, a second positioning hole 42 and a The third positioning hole 43 . The heat dissipation structure 3 includes a back plate 31 and a heat dissipation bottom plate 32 .

[0045] The back plate 31 is arranged on the lower surface 40b of the circuit board 4 and combined with a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com