System, method, and apparatus for oilfield equipment prognostics and health management

A technology of oilfield equipment and equipment, which is applied in the direction of measuring devices, general control systems, wellbore/well valve devices, etc., and can solve problems such as adapting to a specific piece of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0049] Example 1: Relationship Analysis

[0050] see Figure 9 , provides illustrative data 900 in which four (4) readings are obtained from temperature and pressure sensors of an oilfield equipment unit. The first data point reads 178°F, 76 psi; the second data point reads 180°F, 80 psi; the third data point reads 170°F, 70 psi; and the 4th data point reads 172°F, 74 psi. The average of the 4 data points is 175°F, 75 psi. Comparing these data points to each other and calculating the distance of each point from the mean, we obtain the following numbers: 1st data point = 3.16, 2nd data point = 7.07, 3rd data point = 7.07, and 4th data point = 3.16. exist Figure 9 These values are plotted against Euclidean distance 902 in . With respect to the Euclidean distance 902, data points 1 and 4 are closest to the mean, and data point 3 is farthest from the mean.

[0051] However, Figure 9 The analysis presented in does not take into account the distribution of temperature and ...

example 2

[0052] Example 2: Fluid Analysis Machine

[0053] Exemplary embodiments of the current application include the use of MVSPC to check the accuracy of three fluid analysis machines. For ease of reference, the three flow analyzers are referred to as α, β, and γ. Seven parameters are collected for analysis: cell temperature, flow rate, downstream flow, upstream flow, liquid flow, permeability, and conductivity. exist Figure 11 to Figure 15 The results are shown in .

[0054] see Figure 11 , the average permeability of each fluid analyzer (Y-axis) is plotted against the time frame of the measurement (X-axis). The α1102 proved to be the most stable machine as the permeability readings were consistently at levels between 205 and 215. β1104 and γ1106 show indications of potential abnormalities. Permeability readings for β1104 showed a steady increase from about 210 to about 300. For γ1106, the permeability readings fluctuated considerably around timeframes 10-14 and again aro...

example 3

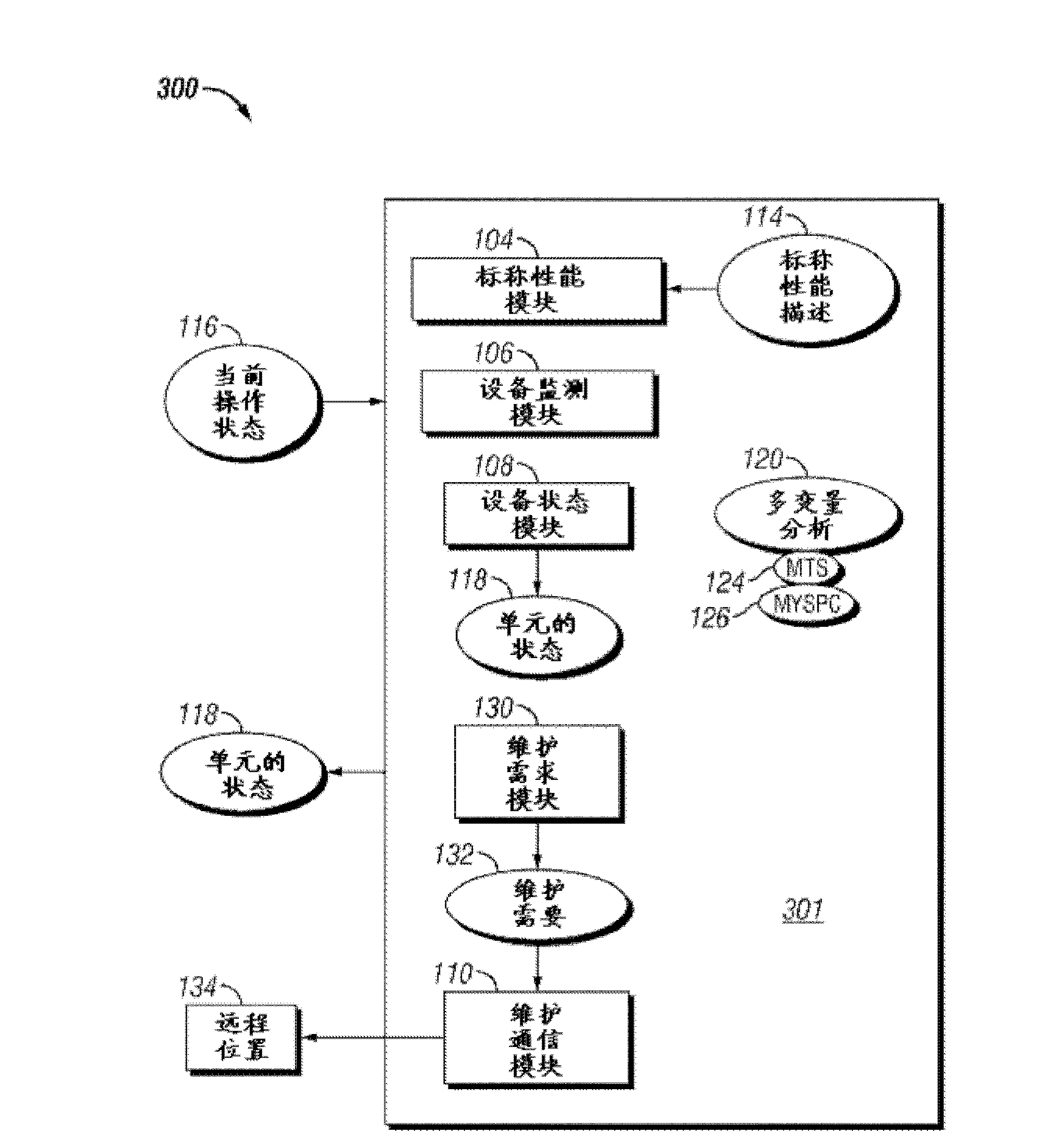

[0057] Example 3: Oil Field Pump

[0058] see Figure 16 , system 1600 uses a knowledge-based system to accelerate process / equipment fault detection and classification, and uses advanced statistical techniques to monitor equipment health and identify anomalies. Data 1604 is determined from a plurality of sensor channels (eg, accelerometers 1602 ) related to pump failure and normal pump operation. Based on a multivariate analysis, an exemplary data set 1610 is provided to an operator, including current equipment health status 1612 (e.g., good, failed, suspect, etc.) and projected life expectancy 1616 (e.g., hours hours, etc.). Another exemplary data set 1608 may further be provided by the remote communication device 1606, eg, communicated to maintenance personnel. Exemplary data set 1608 includes current equipment health status 1612 and maintenance preparation steps 1614 . Maintenance preparation step 1614 may include a need for repair / maintenance, an indicator that repair / ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com