Cavity wall structure and cavity wall plate of liquefied natural gas cargo tank

A technology for liquefied natural gas and cavity walls, which is applied to the outer walls of container structures, gas processing/storage purposes, and hull panels, etc. Possibility, easy operation, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

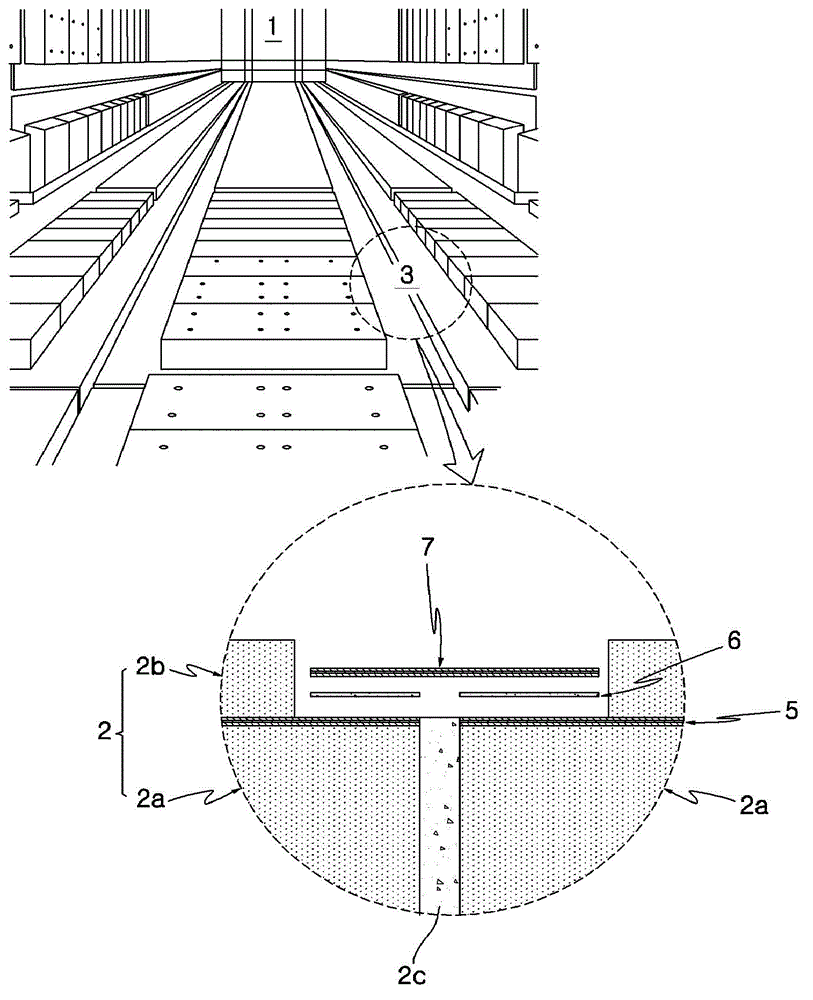

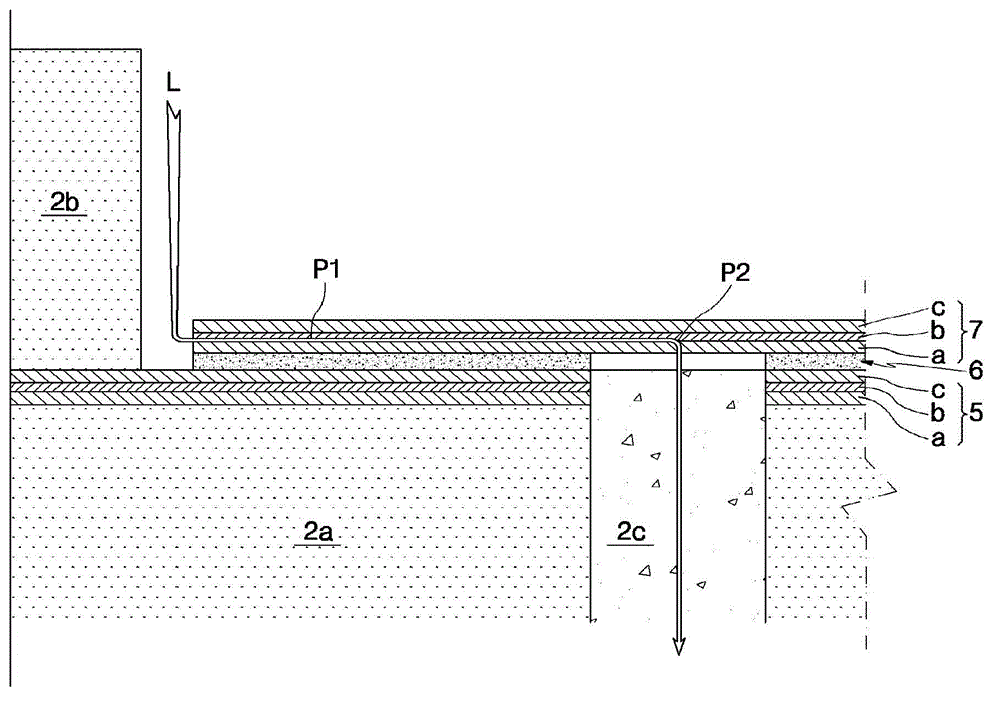

[0033] Below, refer to Figure 2 to Figure 4 , the cavity wall plate and cavity wall structure of the liquefied natural gas cargo tank according to the embodiment of the present invention will be described in detail. Throughout the drawings, the same or similar reference numerals represent the same or similar constituent elements.

[0034] The following specific examples are only used to illustrate the chamber wall plate and chamber wall structure of the LNG cargo tank according to the present invention, and are not intended to limit the scope of the present invention.

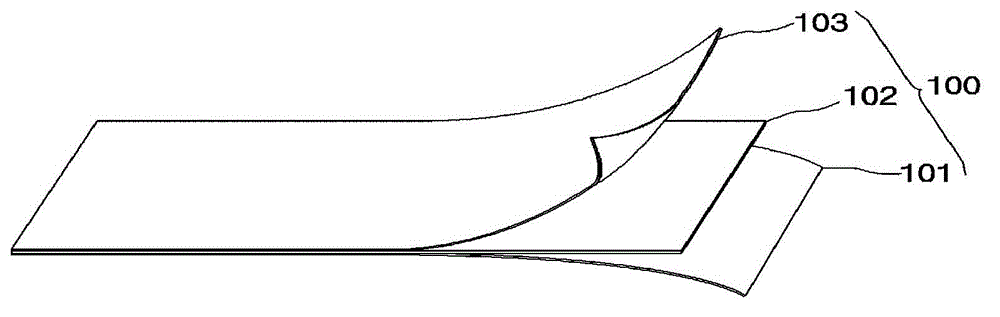

[0035] figure 2 It is a structural diagram of the cavity wall plate used in the cavity wall structure of the liquefied natural gas cargo tank according to an embodiment of the present invention.

[0036] like figure 2 As shown, for the secondary cavity wall of the LNG cargo tank, the cavity wall plate 100 of the LNG cargo tank according to an embodiment of the present invention can be made into a sandwich s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com