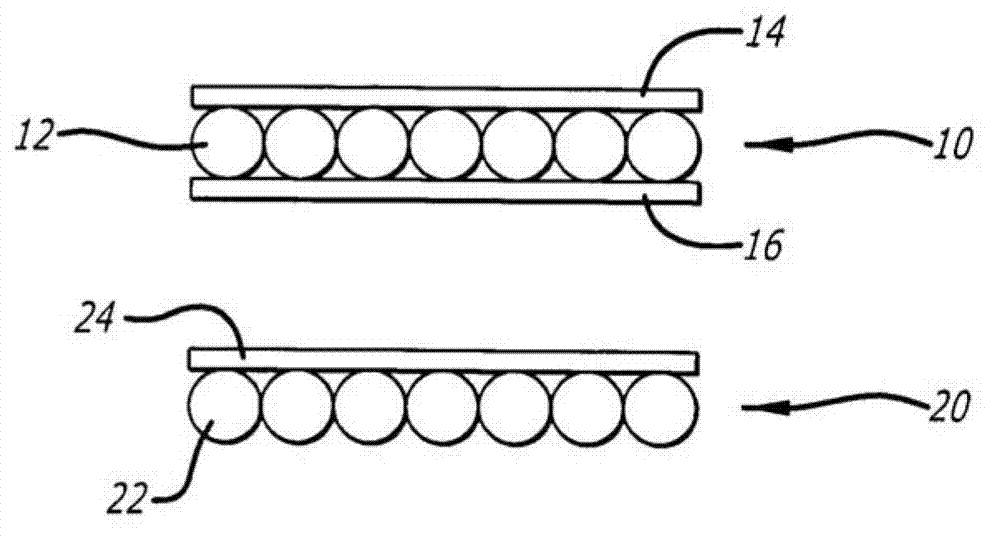

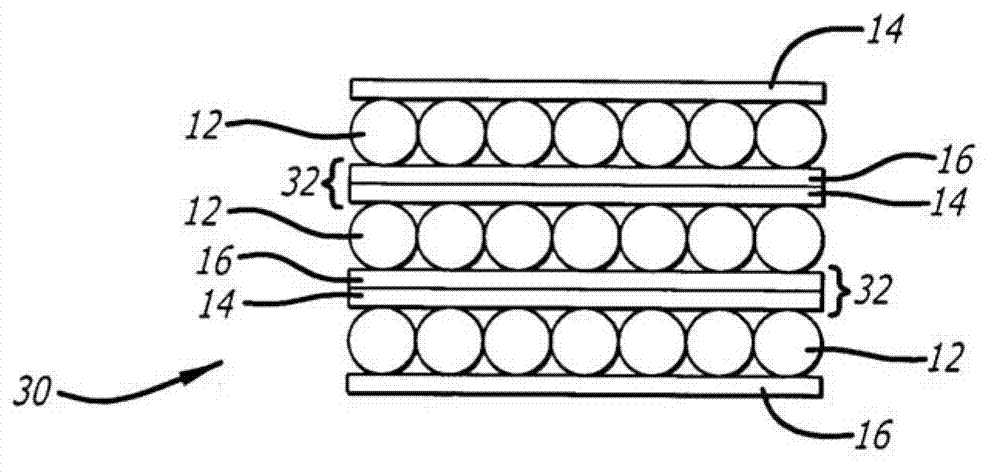

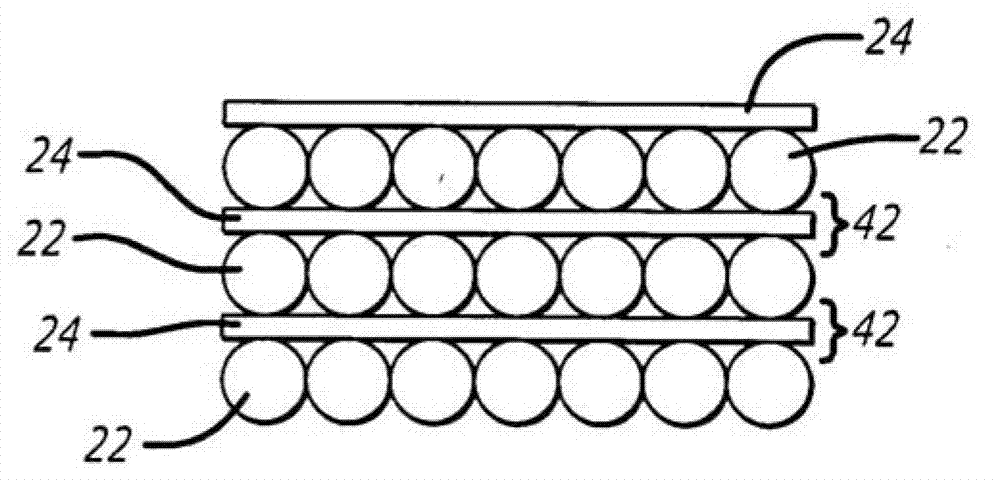

Structured thermoplastic in composite interleaves

A structured, thermoplastic technology that can be used in lamination, layered products, lamination devices, etc., to solve problems such as poor impact resistance and easy delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Example 1 (prepreg A)

[0087] A 145gsm IM7-12K UD fiber sheet surrounded on two sides by an open structure sheet (4gsm (128D04 from Protecnic, France)) was fabricated. Prepregs were fabricated from this open structure sheet and UD fibers by applying a 36 gsm film of epoxy-based M56 resin (MY721 epoxy resin with dissolved polyethersulfone (available from Huntsman) and methylene dianiline curing agent) and passed through compaction rolls to form a prepreg. The resin content of the resulting prepreg was 32%.

Embodiment 3

[0090] Example 3 (prepreg C)

[0091] Prepregs were made by applying a 36gsm M56 resin film to either side of 134gsm AS7-12K UD fibers and passing over compaction rolls. Subsequently, a 128D04 mat was applied to one side of the prepreg before passing through another set of compaction rolls. The resin content of the prepreg obtained according to the invention was 35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com