Wheat combine-harvester with laterally arranged drive conveying groove

A technology of combine harvester and conveying trough, which is used in harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of high labor intensity of drivers, small use range, poor harvest quality, etc., and achieve ideal harvesting effect and operation. Simple, high harvest efficiency results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

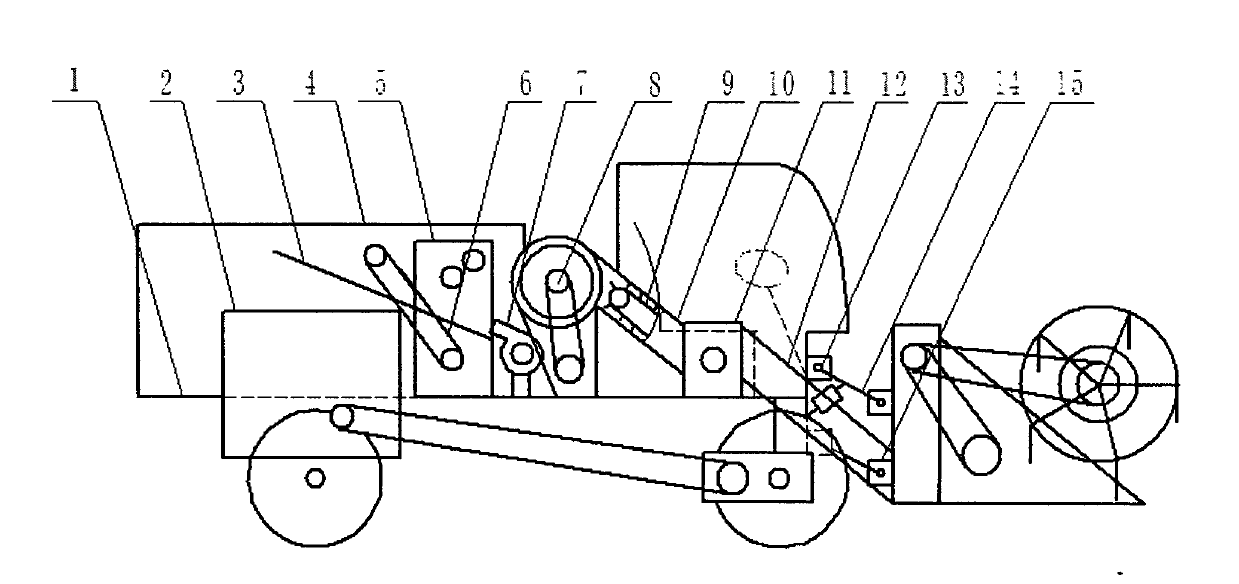

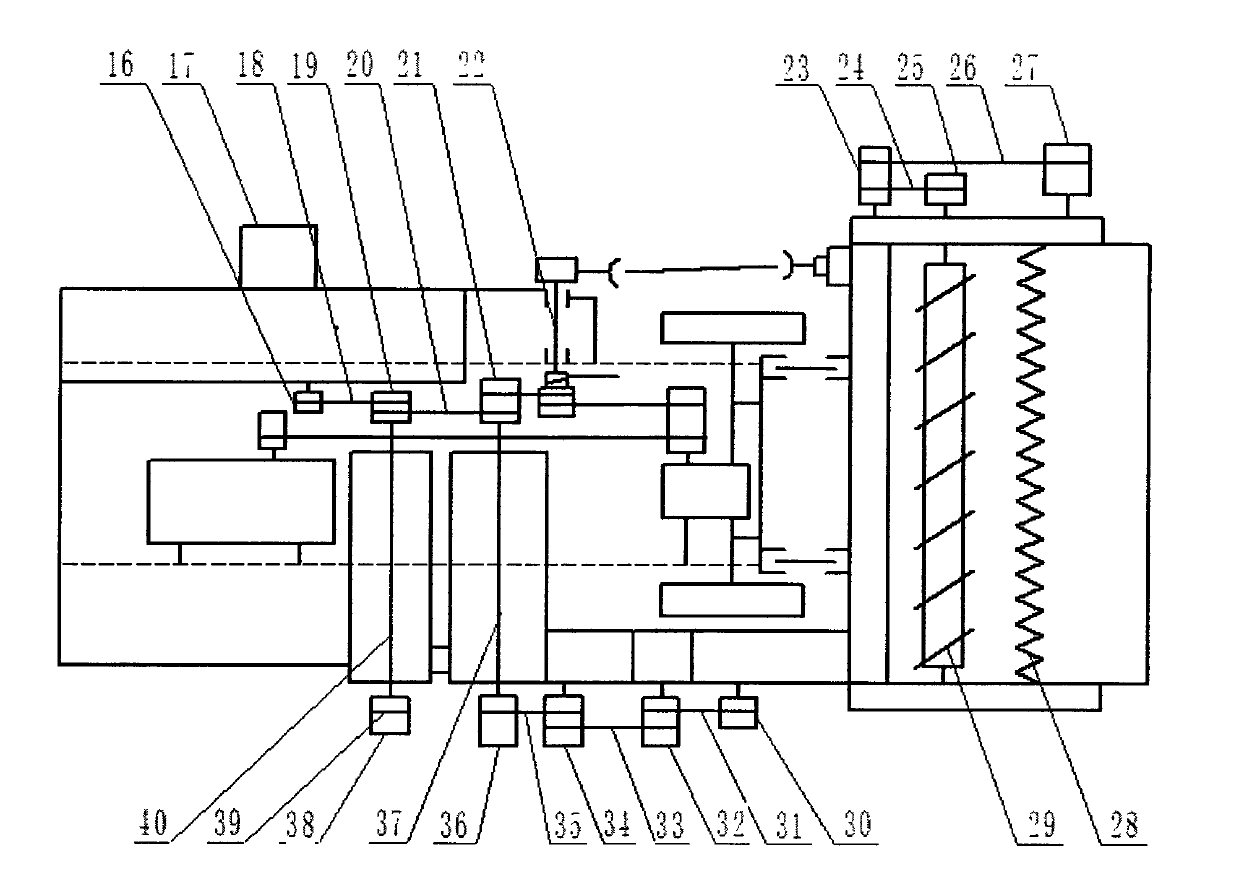

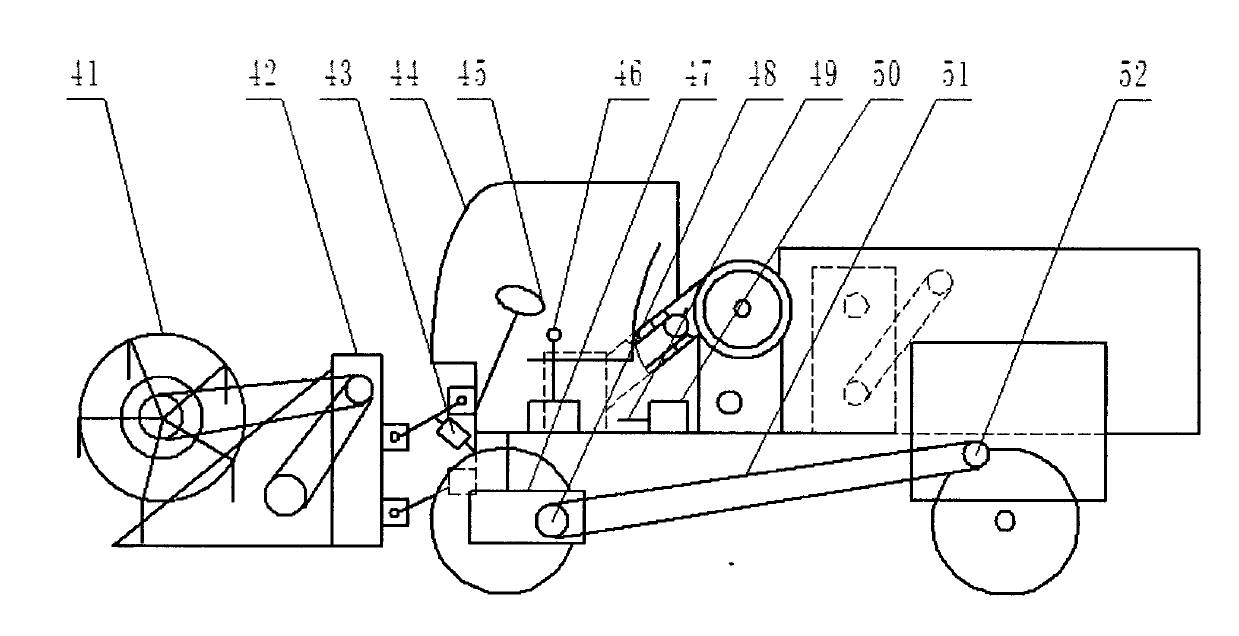

[0014]A side-mounted wheat combine harvester with a belt transmission trough, which consists of a frame 1, an engine 2, a wheat sieve combination 3, a granary 4, a cleaning box 5, a wheat grain lifting system 6, a blower 7, a grain grain lifting system 8, Conveying trough toothed belt and slave shaft roller 9, secondary conveying trough 10, transfer box 11, primary conveying trough 12, rotating shaft 13, connecting rod 14, connecting rod seat 15, wheat grain conveyor pulley 16, granary outlet 17, granary belt 18. Left wheel 19 on the cleaning box, left belt 20 on the cleaning box, left wheel 21 on the threshing drum assembly, 22 harvesting main shaft assembly, cutter pulley 23, cutter belt 24, wheat ears conveyor pulley 25, reel Belt 26, reeling pulley 27, cutter 28, ear conveyor 29, primary grooved pulley 30, primary grooved belt 31, transfer case pulley 32, transfer case belt 33, secondary grooved pulley 34, Secondary groove belt 35, threshing drum assembly right pulley 36, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com