Fully-automatic bean stick rolling machine

A fully automatic, rolling machine technology, used in dairy products, cheese substitutes, food forming and other directions, can solve the problems of high labor cost, poor rolling quality, low rolling efficiency, etc., to reduce labor intensity, roll Improve the production efficiency and solve the effect of low rolling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

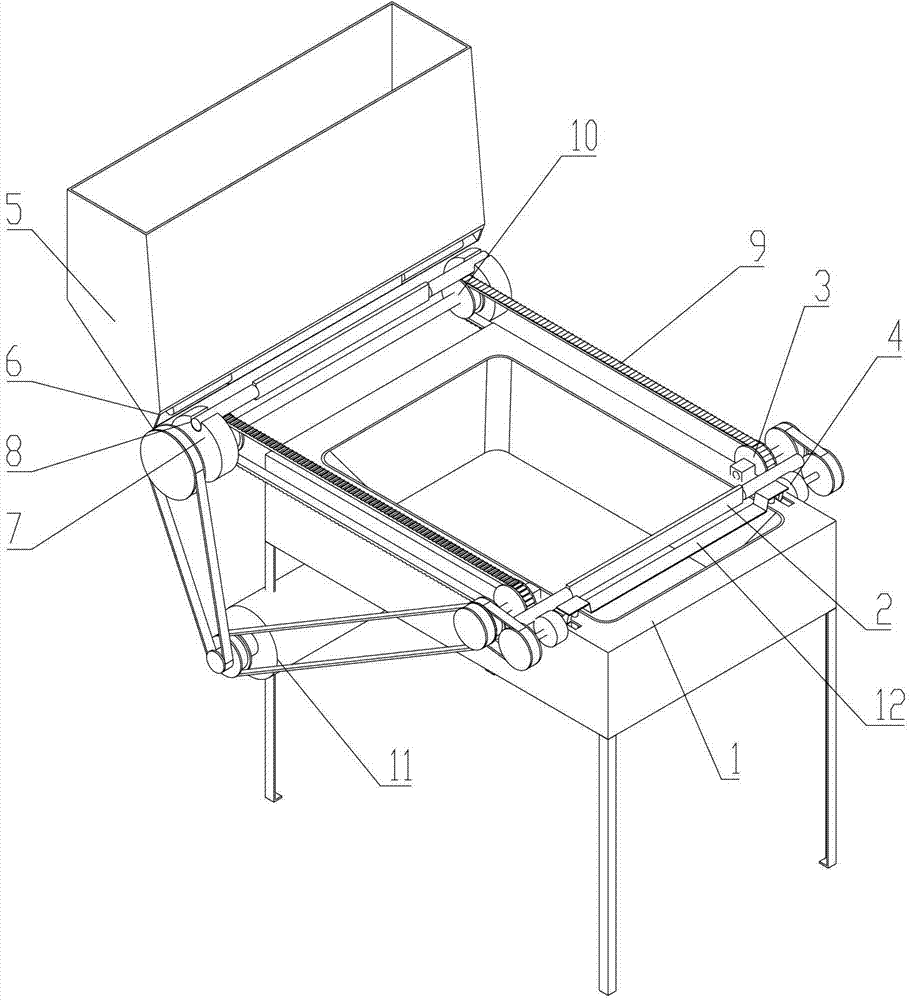

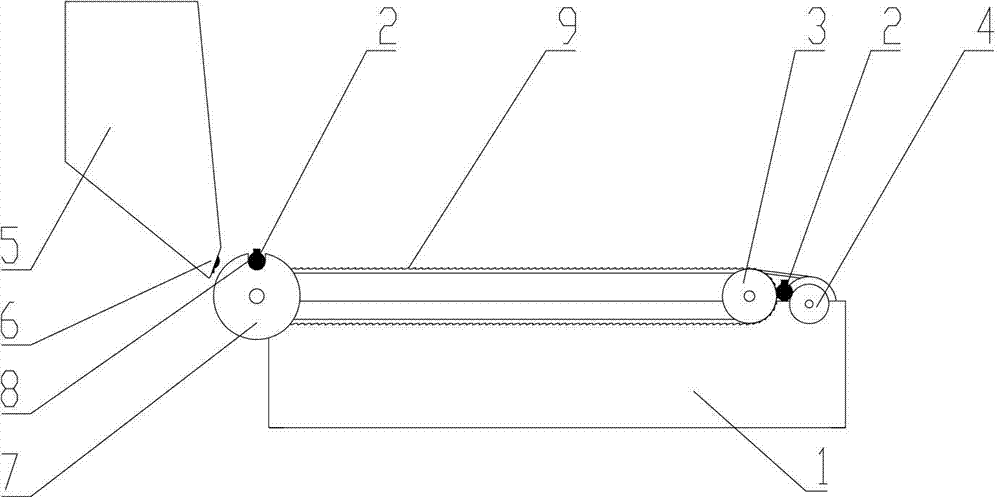

[0029] As a specific implementation of the above technical solution, such as figure 1 and 2 As shown, the roll feeding device also includes a conveyor belt 9 and a driven wheel 10, the driven wheel 10 is driven and matched with the driving wheel 3 through the conveyor belt 9, and the roller shifting wheel 7 is set close to the driven wheel 10 to transport the roll 2 to conveyor belt 9. During work, the dial roller 7 that contains the winding roller in the gap 8 first conveys the winding roller 2 to the conveyor belt 9 close to the driven wheel 10, and then is transferred between the driving wheel 3 and the support member 4 by the conveyor belt 9. The roll feeding device has the advantages of simple structure and low production cost.

Embodiment 2

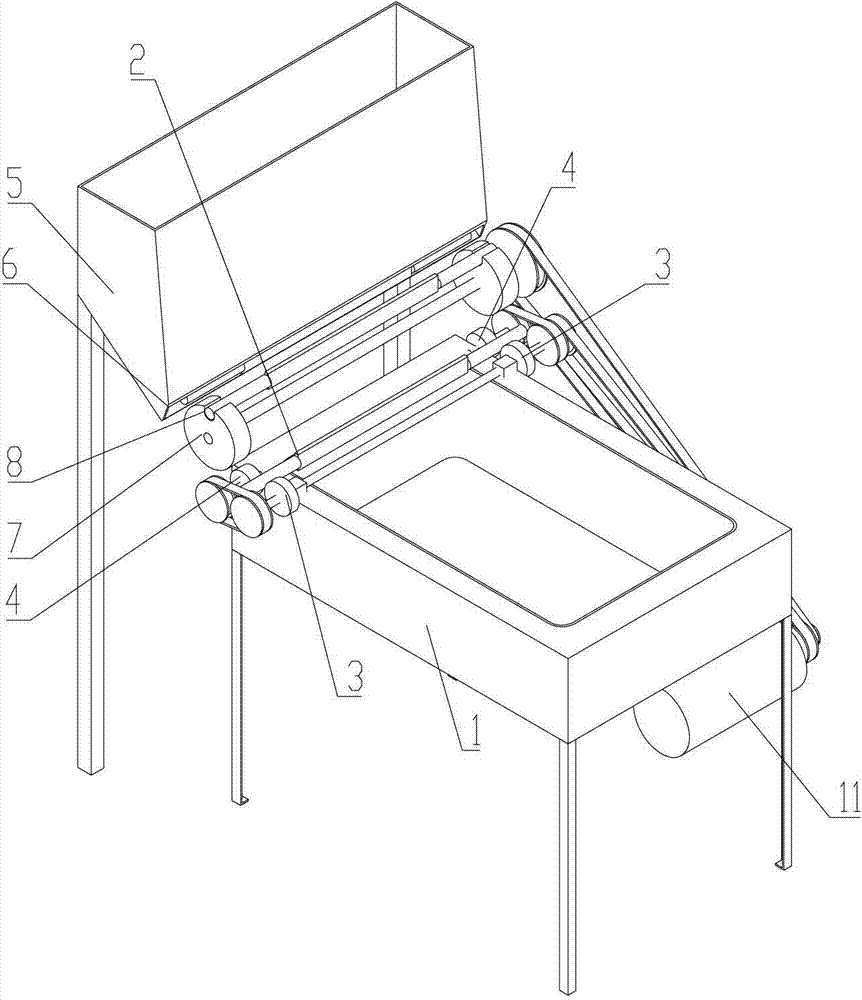

[0031] As another specific implementation of the above technical solution, such as image 3 and 4 As shown, the roll feeding device is arranged above the roll driving device, and the roll shifting wheel 7 is set close to the driving wheel 3 or the supporting member 4 to directly transport the rolling roll 2 between the driving wheel 3 and the supporting member 4 . In the roll feeding device in this embodiment, the shifting roll 7 can directly transport the winding roll 2 between the driving wheel 3 and the support member 4, thereby eliminating the need for conveying structures such as driven wheels and conveyor belts, making the present invention fully automatic. The structure of the bean stick rolling machine is simpler, which further reduces the production cost.

[0032] As a further improvement of the above technical scheme, such as Figure 5 As shown, the support member 4 is in the shape of a wheel or a hook. When the supporting part 4 is in the shape of a wheel, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com