Robot deburring machine

A deburring machine and robot technology, which is applied to machine tools suitable for grinding workpiece edges, grinding workpiece supports, grinding machines, etc. Solve the problem of not being able to adapt to large-scale flexible production, solve the effect of low efficiency and poor quality, and efficient and high-quality flexible deburring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

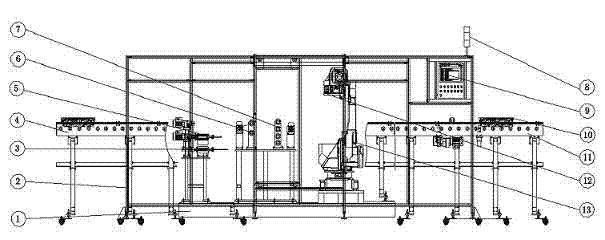

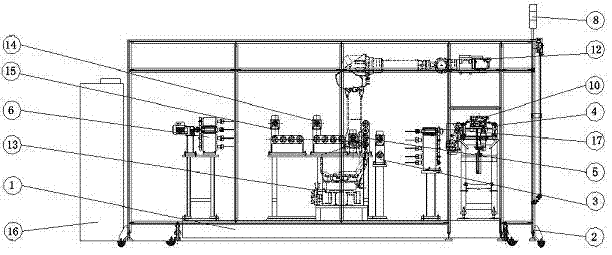

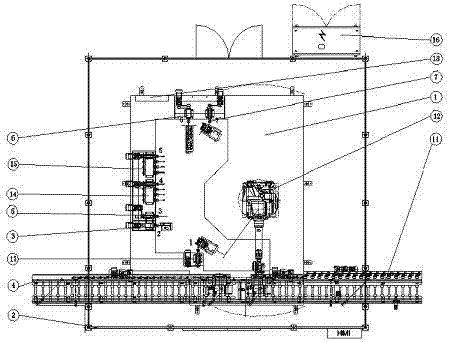

[0012] The invention provides a robot deburring machine, which includes a body, a bracket 1, and a protection 2, and is characterized in that: a feeding raceway 4, a deburring device, a robot 13, a manipulator clamping device 12, and a feeding raceway 11; The raceway 4 near the end of the robot 13 is provided with a deburring device, the body and the support 1 are provided with a robot 13, and the robot 13 is provided with a manipulator clamping device 12, and the robot 13 is installed between the feeding raceway 4 and the unloading raceway 11. Between the machine body and the bracket 1, the deburring device, the robot 13 and the manipulator clamping device 12, the protection 2 is installed outside.

[0013] The centers of the feeding raceway 4 and the discharging raceway 11 are on the same axis.

[0014] The deburring device has 7 sets of deburring brushes.

[0015] Among them, the deburring devices are deburring device I17, deburring device II3, deburring device III5, debur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap