Disk-type polishing machine

A polishing machine, disc technology, applied in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., to achieve the effect of reducing production costs, convenient operation, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

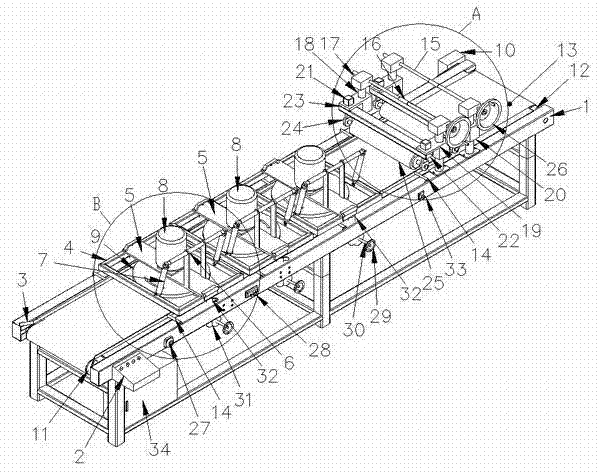

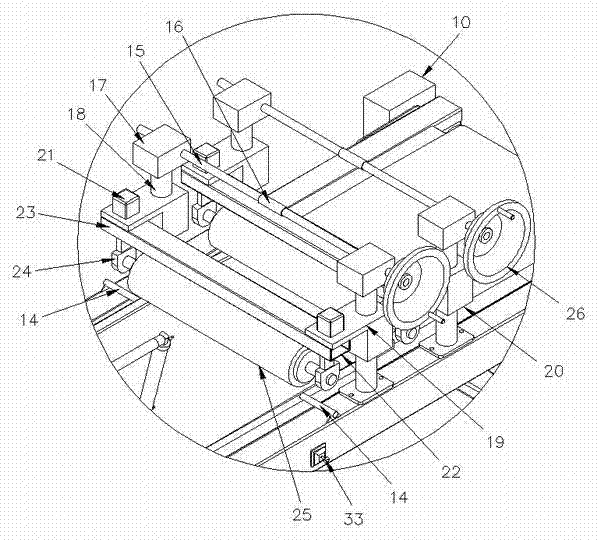

[0015] figure 1 , 2 , 3 shows the structure of a disc polishing machine. In the figure, a disc polishing machine includes a frame 1, a disc polishing device, a distribution box 34 and a brush coloring device. The two ends of the frame 1 are respectively provided with a conveying driving roller 12 and a conveying driven roller 11, which are connected together by a conveying belt 13, and the conveying driving roller 12 uses a conveying power device 10 to drive the conveying belt 13 to move.

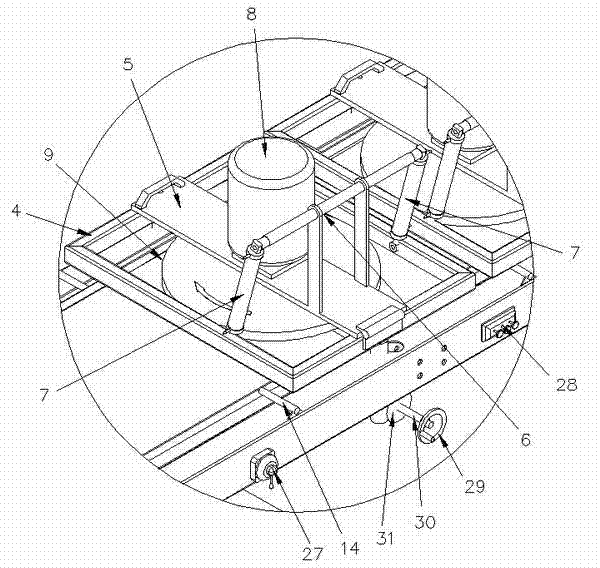

[0016] Three disc polishing devices are arranged in the middle of the frame 1, and each disc polishing device adjusts its working position through its own first adjustment mechanism. The disc polishing device uses a motor 8 to drive the polishing disc 9, the motor 8 is fixed on the motor flap 5, one end of the motor flap 5 is hinged to the motor support frame 4, and the turning cylinder bracket 6 fixed on the motor flap 5 Each hinge at both ends is connected with a pneumatic overturning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com