Processing method for ceramic-imitated sculpture

A processing method and technology of imitating ceramics, applied in the field of imitating ceramics, can solve problems such as uneven product quality, complex ceramic sculpture process, and inability to reproduce large quantities of production, and achieve low processing cost, good product quality uniformity, and high simulation degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

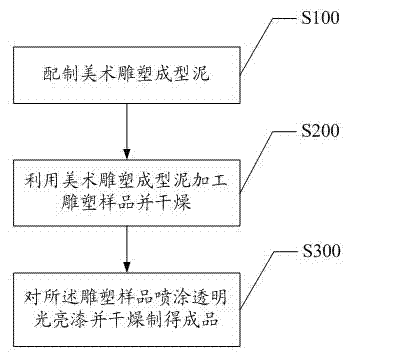

Image

Examples

Embodiment 1

[0031] Prepare art sculpture molding mud: mix component A and component B of art sculpture clay in a weight ratio of 1:1, the component A is epoxy resin, and the component B is a curing agent; after mixing evenly, Add filler to the mixture, wherein the weight ratio between the mixture of component A and component B and the filler is 1:2.5; and according to the color requirements, add 1% of the total weight of art molding clay , to obtain brightly colored art molding clay. Making a skeleton of a sculpture sample, adhering the art sculpture molding clay to the skeleton to form a green body; carving the green body to form a sculpture sample; drying the sculpture sample; grinding and polishing. The sculpture sample is sprayed with transparent glossy varnish and kept at 30°C.

Embodiment 2

[0033] Prepare art sculpture molding clay: mix component A and component B of art sculpture clay in a weight ratio of 1:1, the component A is epoxy resin, and the component B is a curing agent; after mixing evenly, Add filler to the mixture, wherein the weight ratio between the mixture of component A and component B and the filler is 1:1.5; and according to the color requirements, add 5% of the total weight of art molding clay , to obtain brightly colored art molding clay. Making a skeleton of a sculpture sample, adhering the art sculpture molding clay to the skeleton to form a green body; carving the green body to form a sculpture sample; drying the sculpture sample; grinding and polishing. The sculpture samples were sprayed with transparent varnish and kept at 25°C.

Embodiment 3

[0035] Prepare art sculpture molding clay: mix component A and component B of art sculpture clay in a weight ratio of 1:1, the component A is epoxy resin, and the component B is a curing agent; after mixing evenly, Add fillers to the mixture, wherein the weight ratio between the mixture of component A and component B and the filler is 1:1; and according to the color requirements, add 10% of the coloring material accounting for the total weight of art molding clay , to obtain brightly colored art molding clay. Making a skeleton of a sculpture sample, adhering the art sculpture molding clay to the skeleton to form a green body; carving the green body to form a sculpture sample; drying the sculpture sample; grinding and polishing. The sculpture sample is sprayed with transparent glossy varnish and kept at 35°C.

[0036] The preparation of existing ceramics takes a long time, and defects such as cracks are prone to occur in the process of shaping and firing, and the yield of fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com