Wire winding bobbin, wire winding method and wire winding apparatus

A coiling device and line body technology, applied in transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems of scattered winding, loose winding, and inability to ensure endurance value, etc., and achieve the effect of preventing scattered winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] Hereinafter, an embodiment of the present invention will be described using the drawings.

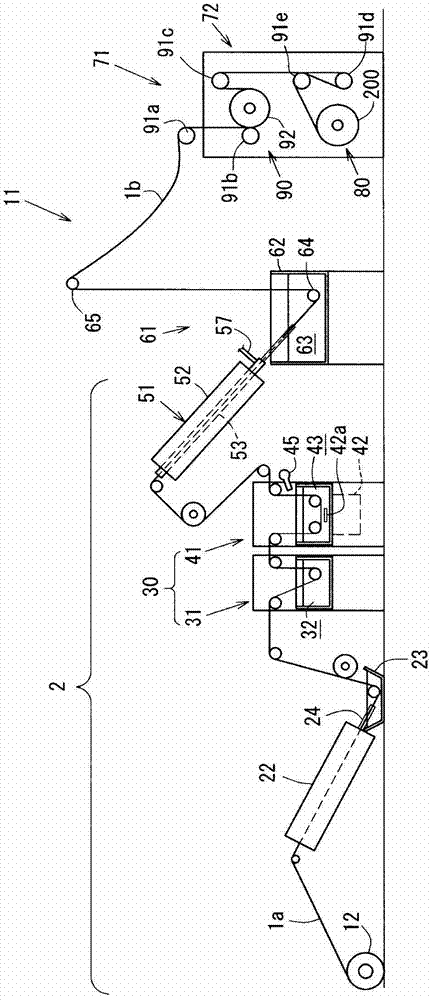

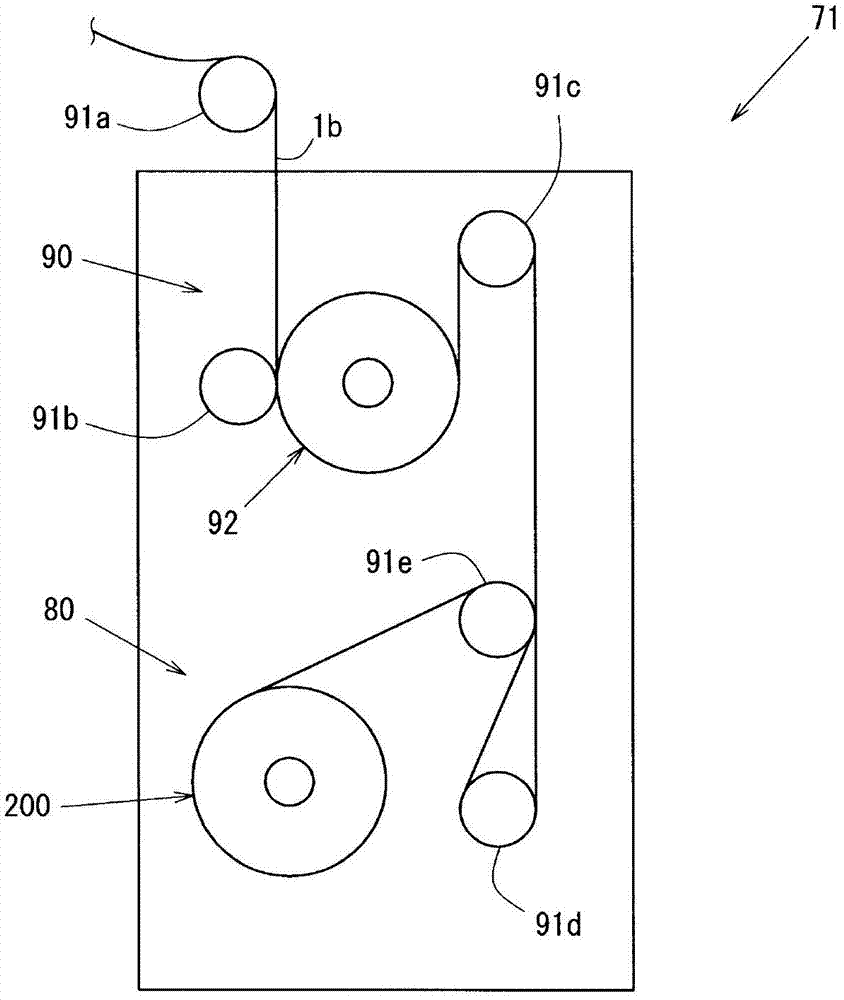

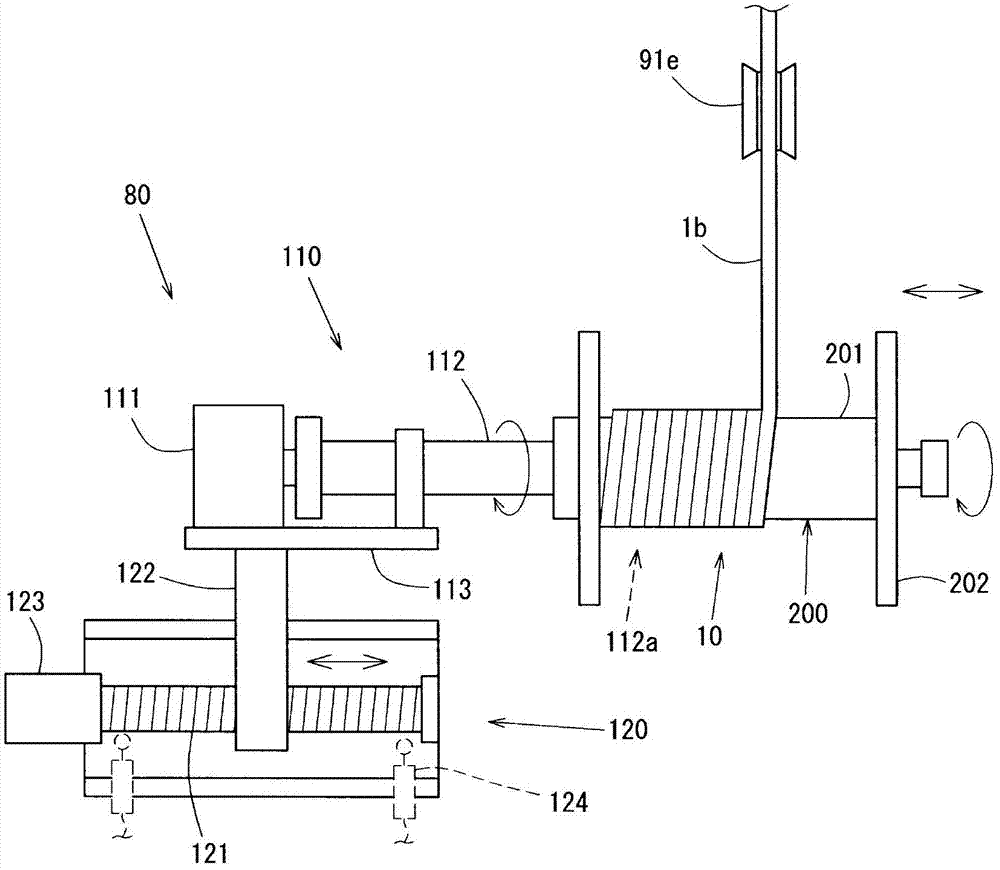

[0102] like figure 1 As shown, the manufacturing device 11 of the brazed plating line of this embodiment includes: a pre-plating mechanism 2 for performing pre-plating treatment on the line to be plated 1a; an electroplating mechanism 61 for performing brazing plating on the surface of the line to be plated 1a; and The winding mechanism 71 which winds up the plating wire 1b whose surface was electroplated.

[0103] figure 1 It is an explanatory drawing which schematically shows the manufacturing apparatus 11 of a solder plating line.

[0104] In the line to be plated 1a, an oxygen-free copper (OFC) is rolled to a thickness of 0.05 to 0.5 mm and a width of 0.8 to 10 mm, more preferably a thickness of 0.08 to 0.24mm, flat-angle copper wire with a width of 1-2mm.

[0105] The electroplating pretreatment mechanism 2 mainly includes: a supplier 12 , a heat treatment furnace 22 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com