Gear fault diagnosis method based on improving multivariable predictive models

A variable prediction model and prediction model technology, which is applied in machine gear/transmission mechanism testing, character and pattern recognition, instruments, etc., can solve problems such as accuracy to be improved, data loss, and impact on classification accuracy, so as to reduce frequency confusion , effective analysis and processing, the real effect of instantaneous amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The fault object in the embodiment of the present invention can be a gear, but is not limited to a gear. After reading the present invention, the gear fault diagnosis method based on the improved multivariate prediction model adopted by those skilled in the art according to the method of the present invention belongs to the protection scope of the present invention. In the specific embodiment, the gear is used as a preferred embodiment to explain the Fangming method, which is not a limiting condition of the present invention. In addition, the present invention does not require strict implementation of the sequence of steps in the following drawings, and any method that can achieve the purpose of fault diagnosis according to the above method belongs to the protection scope of the present invention.

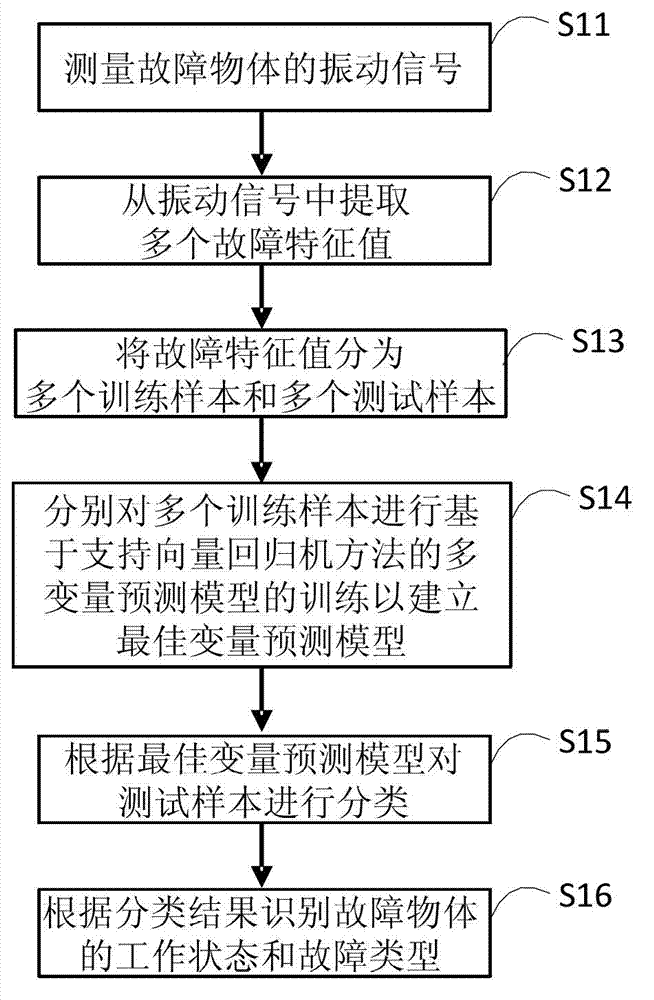

[0040] see figure 1 , figure 1 is a flowchart of the present invention. Concrete implementation of the present invention comprises the steps:

[0041] Step S11, measuring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com