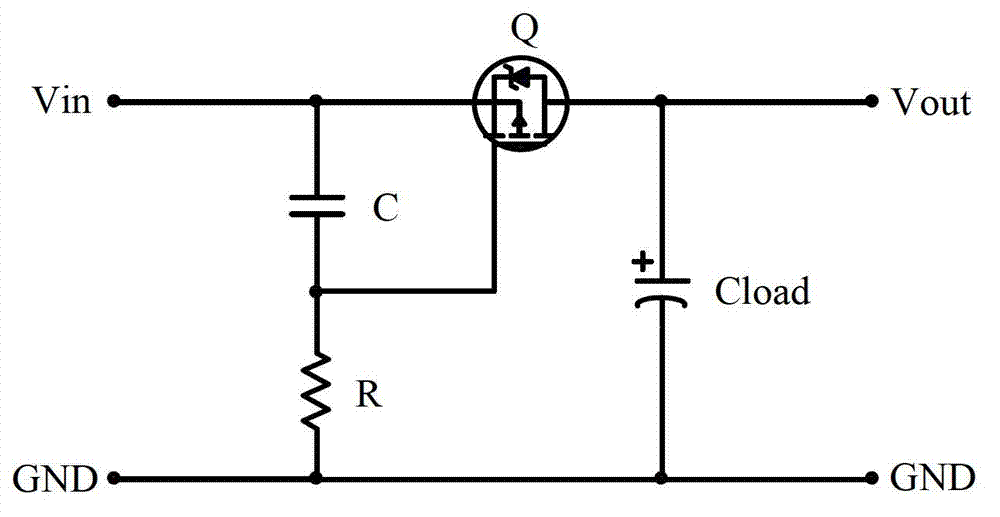

Hot plug circuit, interface circuit and electronic equipment assembly

A hot-swapping and circuit technology, which is applied in the electronic field, can solve the problems of not being able to shut down quickly and poor slow-start effect during power-on, and achieve the effect of improving the effect of slow-start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

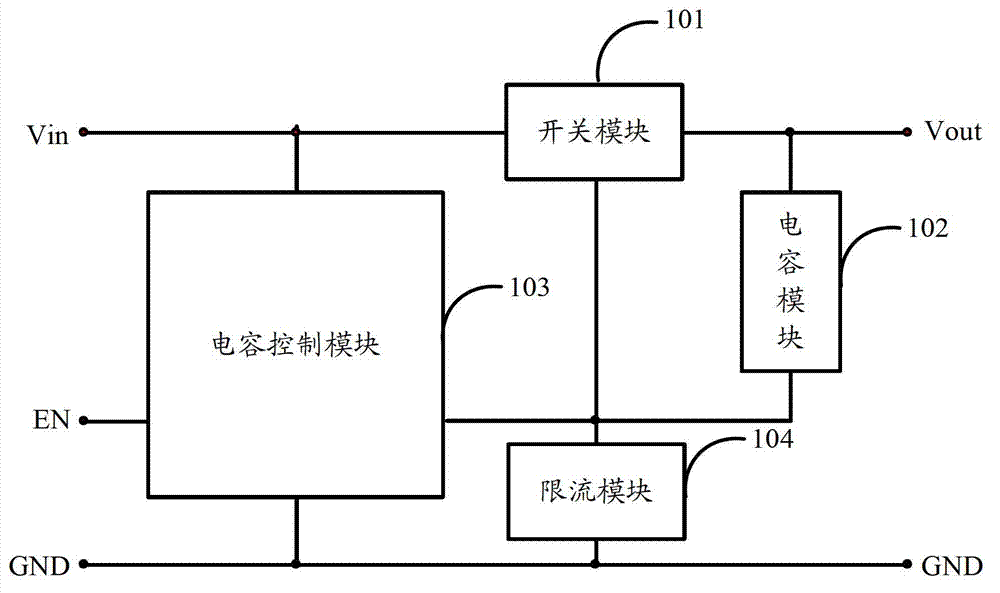

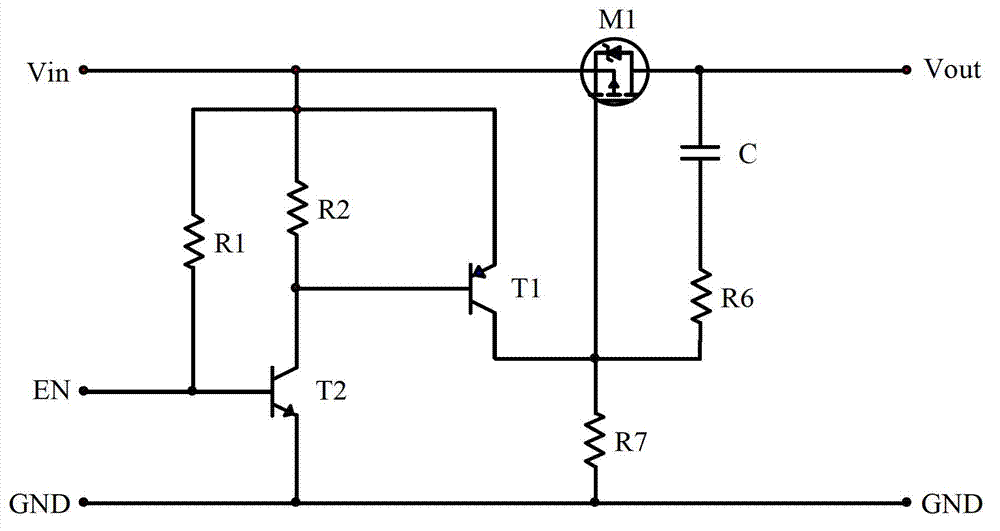

[0028] Embodiment 1 of the present invention provides a positive power supply hot swap circuit, including a switch module 101, a capacitor module 102, a capacitor control module 103 and a current limiting module 104, wherein:

[0029] The first terminal of the switch module 101 is the power input terminal Vin, the second terminal of the switch module 101 is the power output terminal Vout, the third terminal of the switch module 101 and the second terminal of the capacitor module 102, the second terminal of the capacitor control module 103 Four terminals, the first end of the current limiting module 104 are connected; the first end of the capacitor module 102 is the power output terminal Vout; the first end of the capacitor control module 103 is the power input terminal Vin, and the second end of the capacitor control module 102 is the ground terminal GND, the third terminal of the capacitance control module 103 is the enabling terminal EN; the second terminal of the current lim...

Embodiment 2

[0048] Embodiment 2 of the present invention provides a hot swap circuit, including a switch module 101, a capacitor module 102, a capacitor control module 103 and a current limiting module 104, wherein:

[0049] The first terminal of the switch module 101 is the power input terminal Vin, the second terminal of the switch module 101 is the power output terminal Vout, the third terminal of the switch module 101 and the second terminal of the capacitor module 102, the second terminal of the capacitor control module 103 Four terminals, the first end of the current limiting module 104 are connected; the first end of the capacitor module 102 is the power output terminal Vout; the first end of the capacitor control module 103 is the power input terminal Vin, and the second end of the capacitor control module 102 is the ground terminal GND, the third terminal of the capacitance control module 103 is the enabling terminal EN; the second terminal of the current limiting module 104 is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com