Method for improving safety in assembling battery system and packaged battery system

A technology for assembling batteries and battery systems, applied in battery circuit devices, battery pack components, circuits, etc., can solve problems such as negative impact on battery life, and achieve the effect of eliminating time-consuming, eliminating preparation steps, and eliminating sparks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

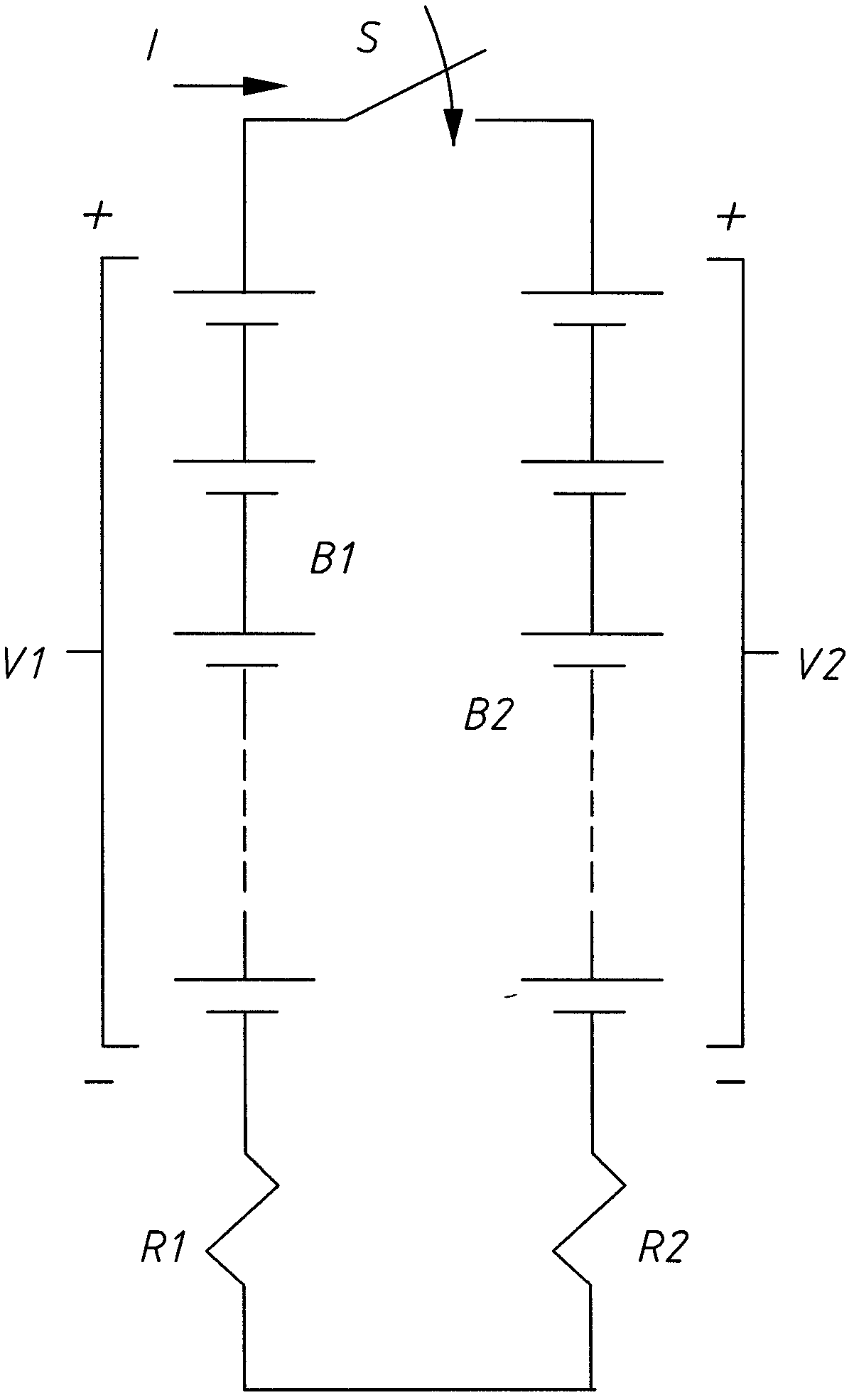

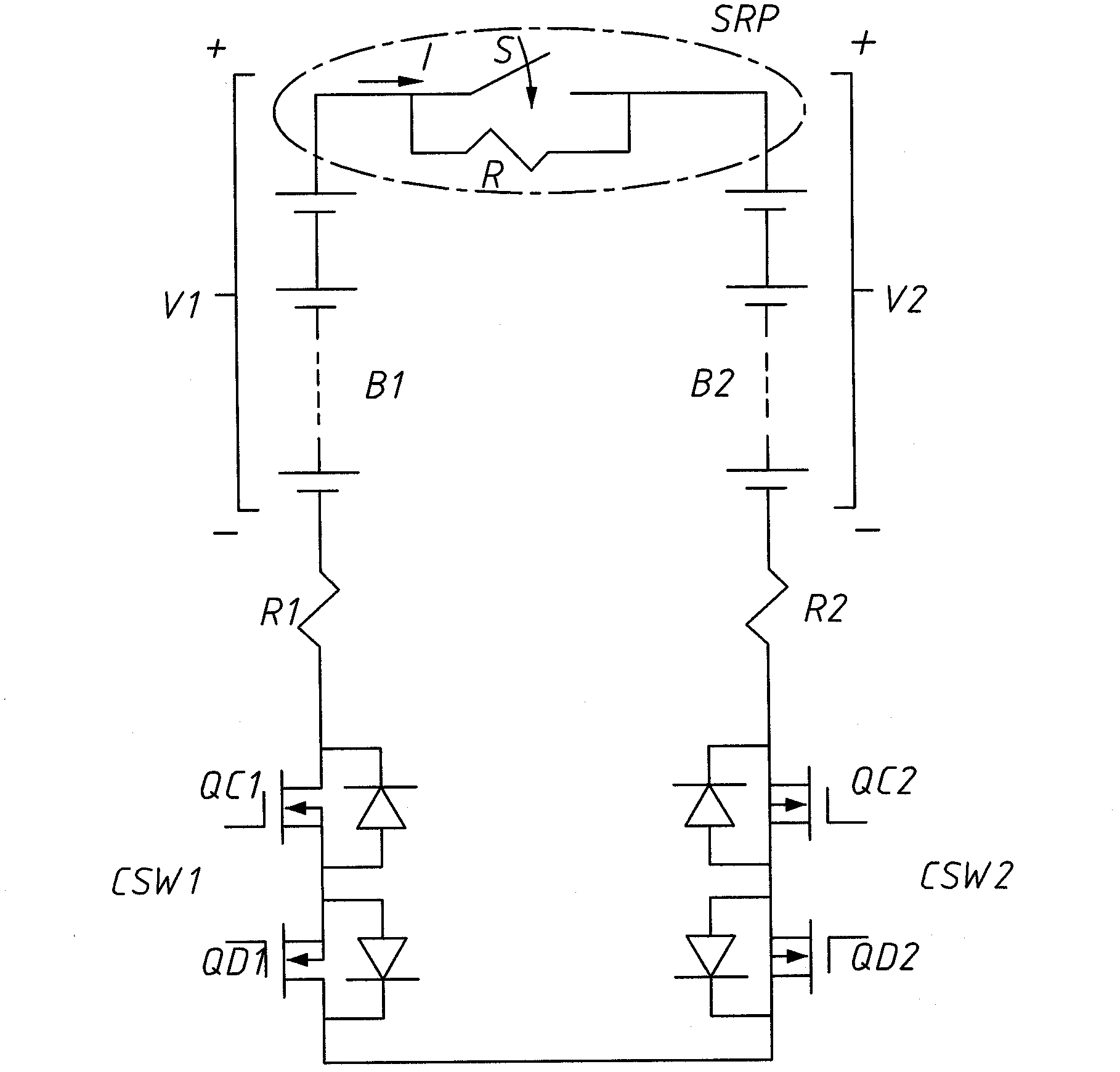

[0039] see figure 2 Solution 1 of the present invention is shown in which a first control switch CSW1 composed of two charging and discharging field effect transistors QC1 and QD1 is connected in series in the first battery branch B1, and a first control switch CSW1 composed of two charge and discharge field effect transistors QC1 and QD1 is connected in series in the second battery branch B2. The second control switch CSW2 composed of the other two charge and discharge field effect transistors QC2 and QD2 is connected to the first battery branch B1 and the second battery branch B2 through a switch-resistor pair SRP.

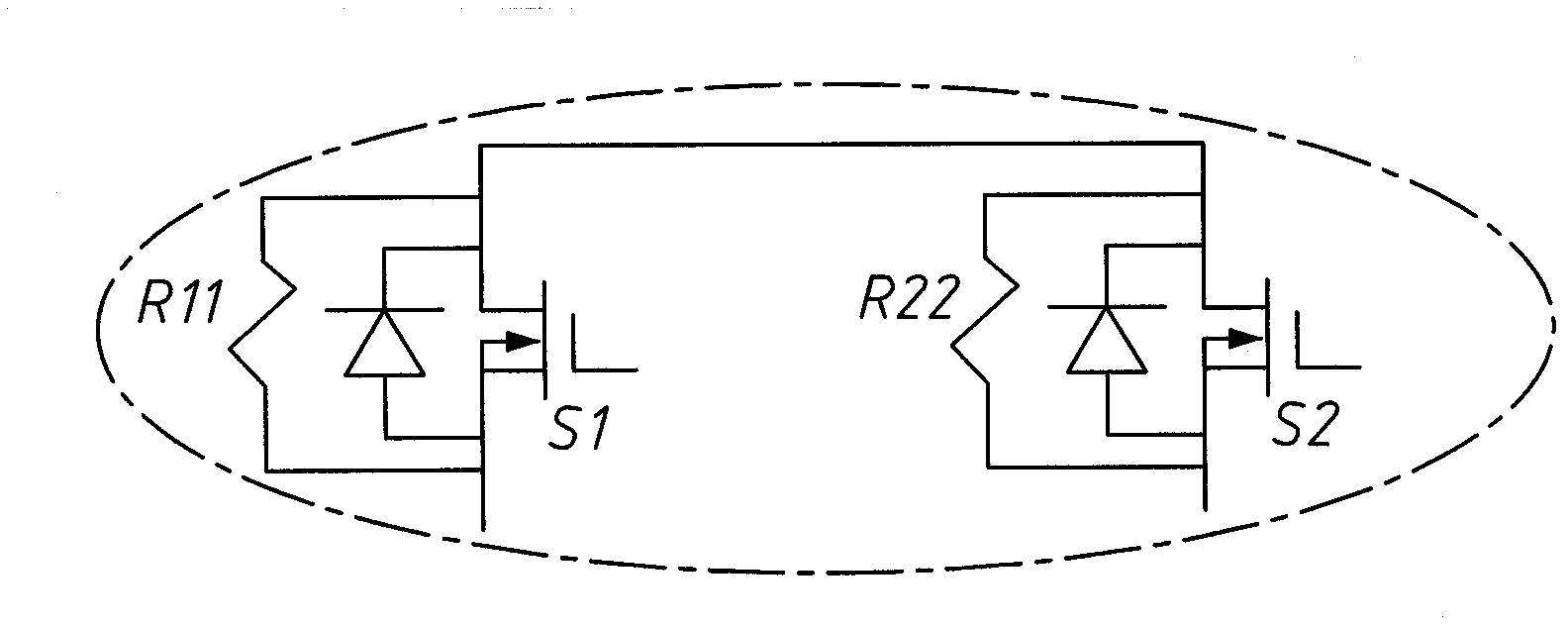

[0040] Solution 1 of the present invention is a simple method to eliminate the arcing effect by using a switch-resistor pair SRP. Switch S in the switch-resistor pair SRP is switched in at a later time when the current level is deemed acceptable. exist image 3 The figure shows that the switch-resistor pair SRP is formed by connecting a first switch S1 compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com