Non-iron-core permanent disc type motor stator and assembly method thereof

A technology for motor stators and core stators, applied in the manufacture of stator/rotor bodies, magnetic circuit shapes/styles/structures, magnetic circuit static parts, etc., can solve problems such as installation, disassembly, and maintenance difficulties, and achieve flexible installation and disassembly , the effect of flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

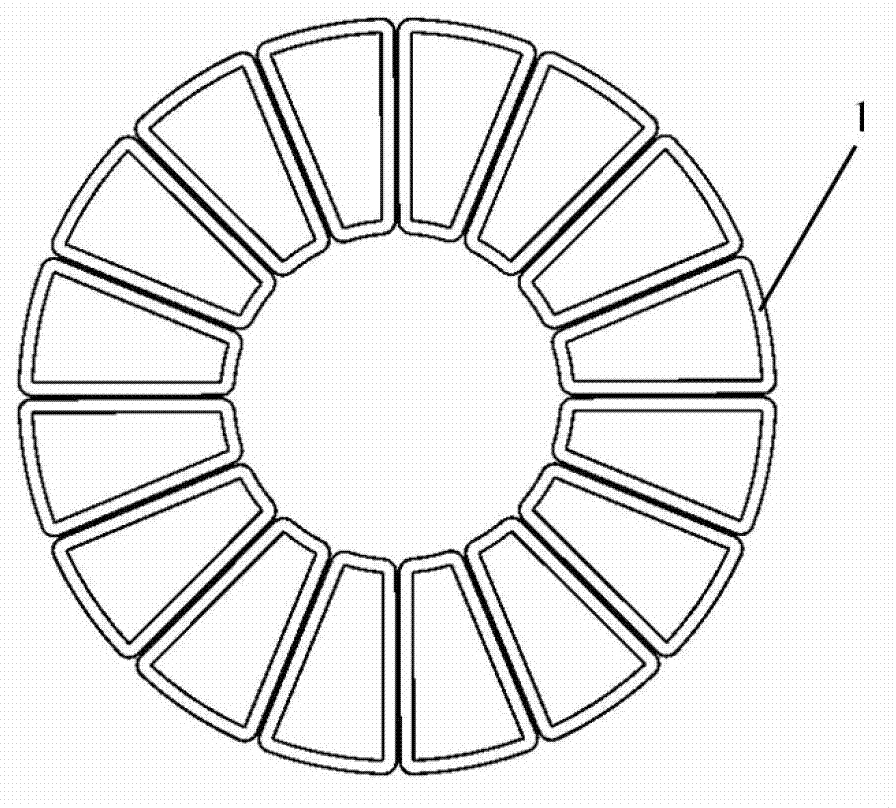

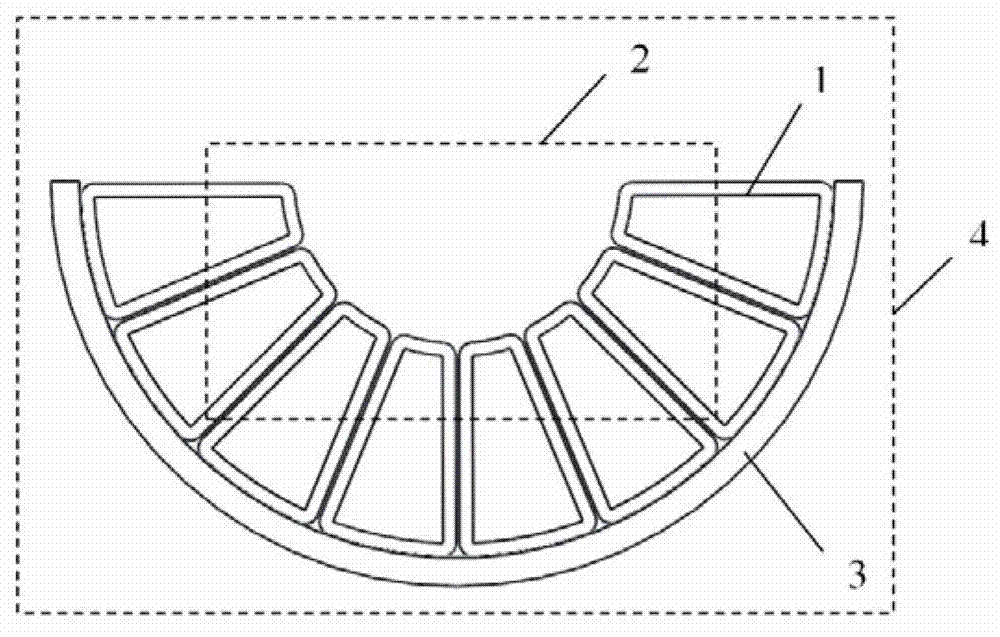

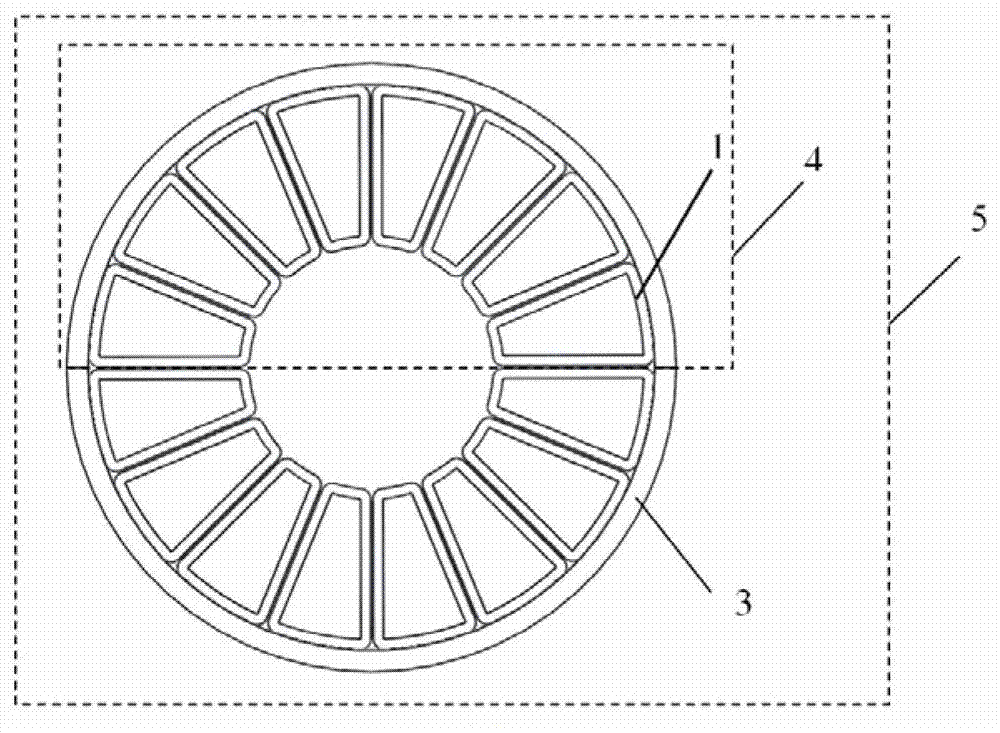

[0031] like figure 2As shown, the modular coreless permanent disk motor stator of the present invention has more than two fan-shaped stator winding modules 4 butt-connected and installed to form a stator winding disk 5 . Each segmented stator winding module 3 includes a segmented stator winding 2 and its corresponding part of the motor housing 3 . It is characterized in that the fan-shaped stator winding is composed of one or more coils 1, and each coil is formed by winding a wire 6 in a certain way. The coils 1 can be arranged in a single layer or double-layered cross arrangement. The traditional The coil arrangement of the whole coil of the coil is applicable here. Part of the motor casing 3 corresponding to the sector stator winding 2 is located outside the sector stator winding 2, and is on the same plane perpendicular to the motor shaft 13 as the sector stator winding 2, and all the sector stator windings have the same central angle. A segmented stator winding 2 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com