Formwork trolley for underground engineering construction and beam and beam column construction method of formwork trolley

A formwork trolley and underground engineering technology, applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve the problems that can not completely eliminate the impact, reduce the weak interface of the node area, construction safety, difficult to control the project quality and schedule

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

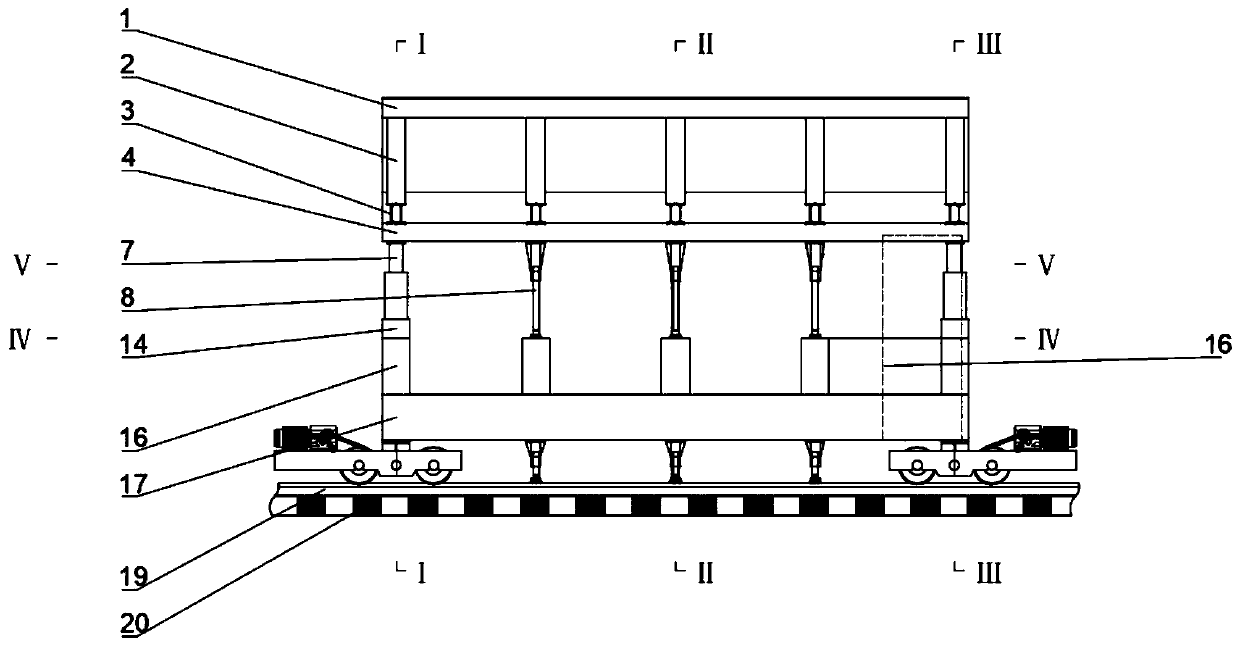

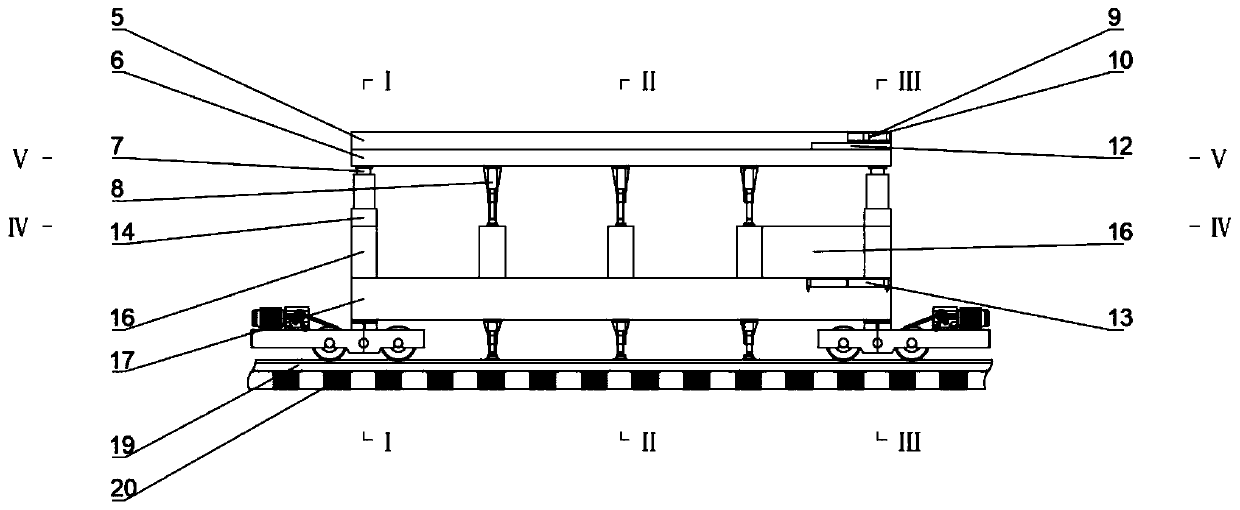

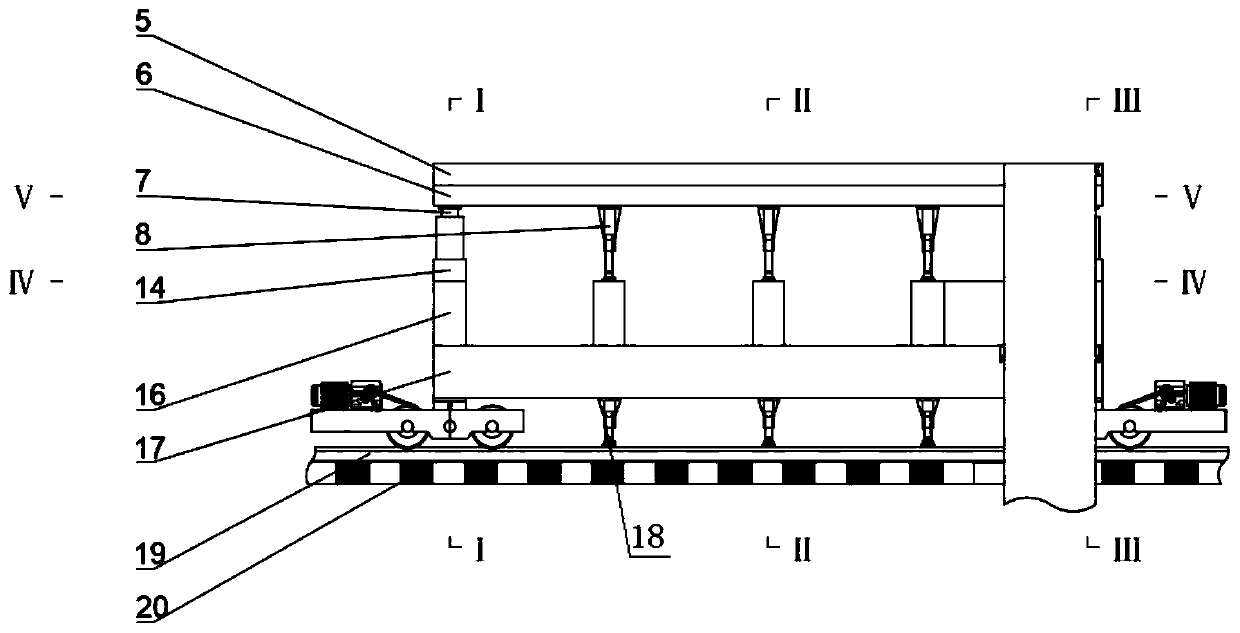

[0059] like Figure 1 to Figure 20 As shown, a formwork trolley for underground engineering construction according to the present invention includes a trolley frame, a right formwork 5 and a left formwork 1 are installed side by side above the trolley framework, and the right formwork 5 and the left formwork 1 Connect with the frame of the trolley through the adjustment assembly A and the transverse guide rail respectively. One end of the bottom mold of the right template 5 is processed with a notch 12, and the inner side of the notch 12 is processed with a clamping mold installation groove, and the clamping mold installation groove A card mold is detachably connected inside, and a traveling mechanism is installed on the bottom of the frame of the trolley, and the traveling mechanism is installed on the sleeper 20 through a longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com