Process for producing a cathode block for an aluminium electrolysis cell and a cathode block

A cathode block and coke technology, applied in the field of cathode blocks, can solve the problems of low wear resistance and low wear resistance of cathode blocks, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] To manufacture the cathode block according to the invention, the first coke and the second coke are ground separately from each other, separated into particle size groups and mixed together with pitch. The proportion by weight of the first coke to the total amount of coke may amount to, for example, 10 to 20% by weight or 40 to 45% by weight. Cathode blocks can be manufactured by extrusion from a raw meal mixture. Alternatively, the mixture can be filled, for example, into a mold which substantially corresponds to the subsequent shape of the cathode block, and the mixture compacted or briquetted by vibration. The formed green body is heated to a final temperature in the range of 2400 to 3000°C, a carbonization step followed by a graphitization step takes place, and is subsequently cooled. The formed cathode block has a 1.71 g / cm 3 Bulk density and high wear resistance for liquid aluminum and cryolite.

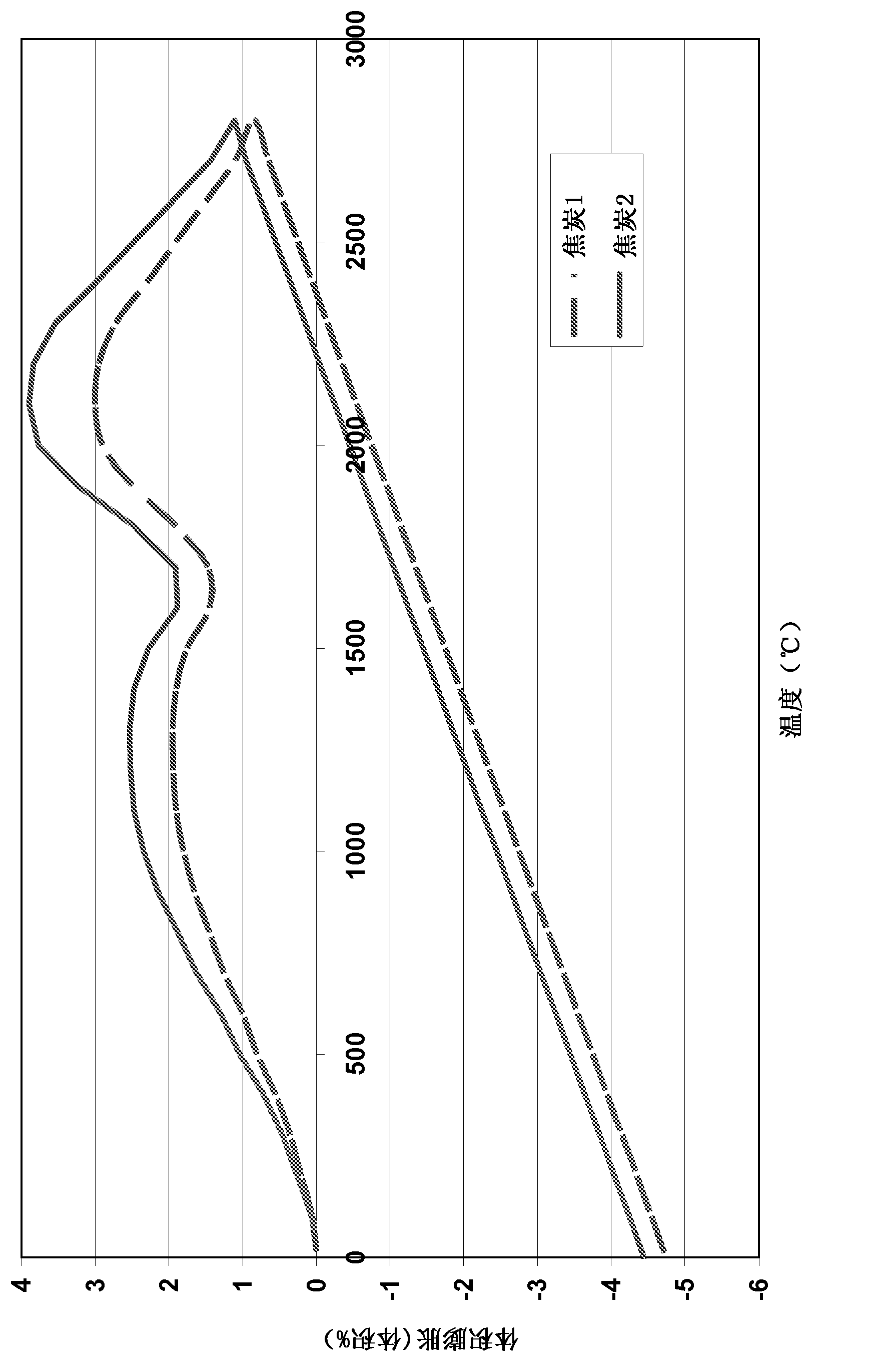

[0035] figure 1 The dilatometer measurement curve (represented ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com