Device for recovering energy

A technology for recovering energy and energy, applied in the direction of accumulator devices, lifting devices, fluid pressure actuating devices, etc., to achieve the effects of simple configuration, reliable operation, and minimized heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

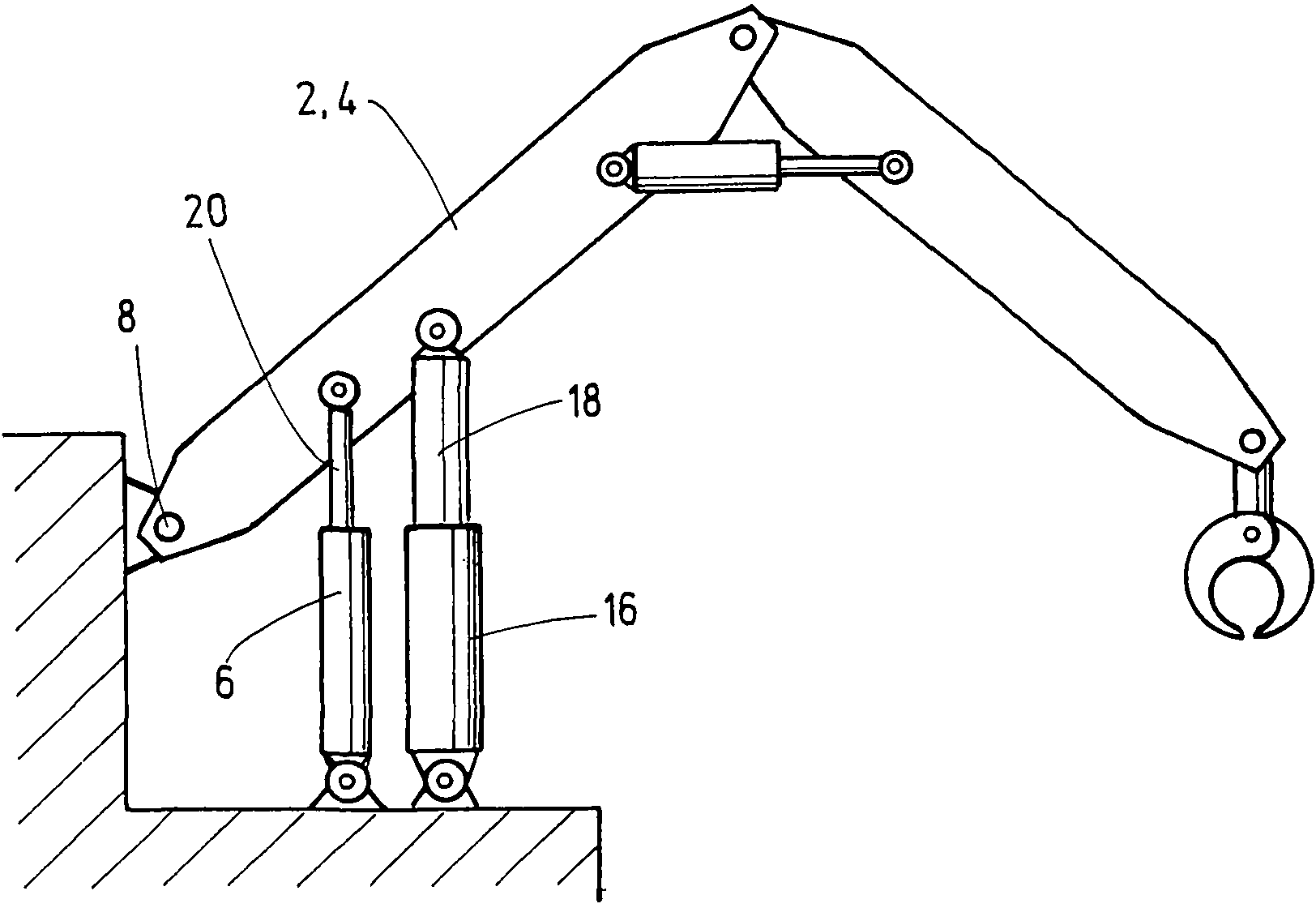

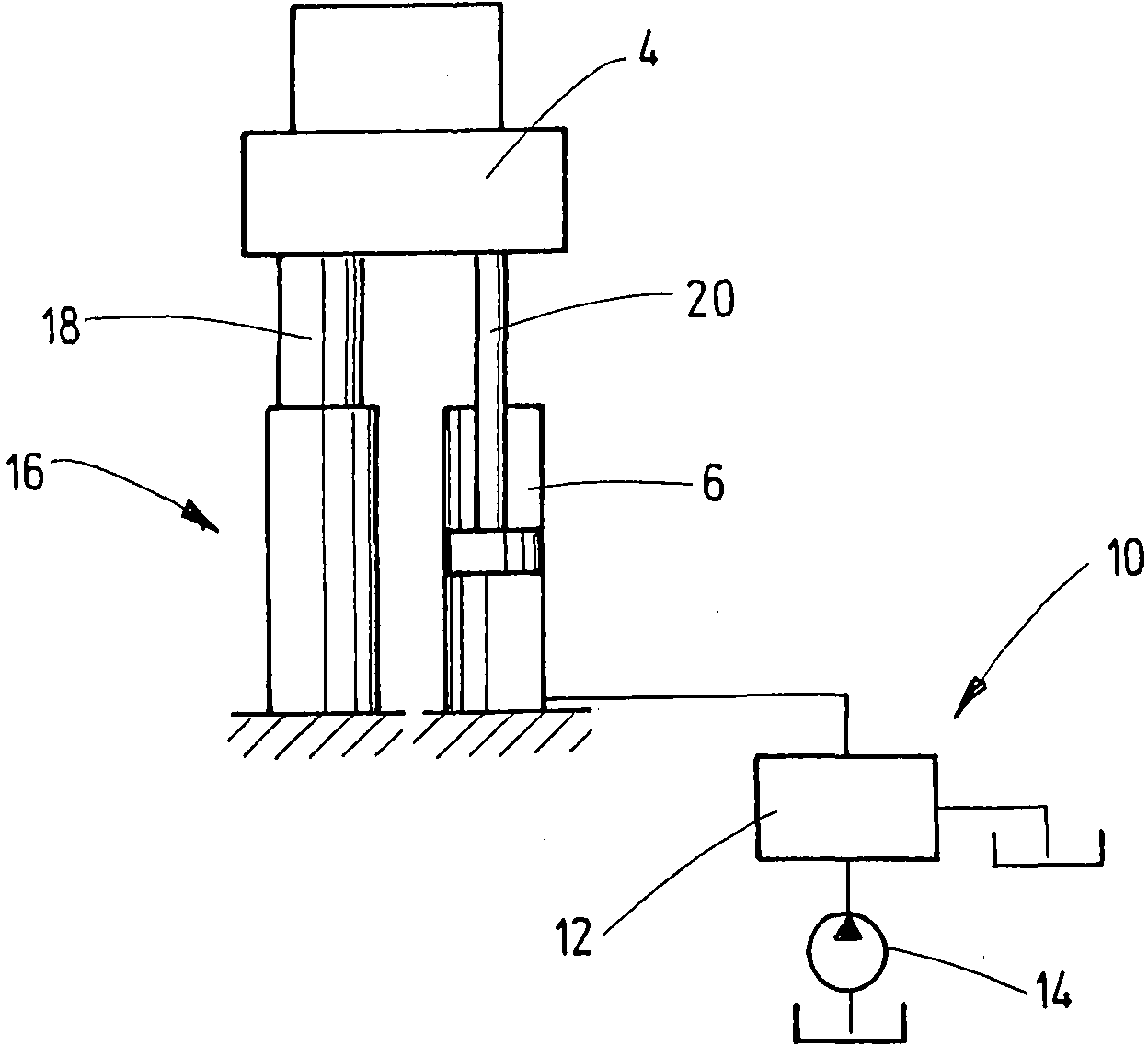

[0024] The invention is described below on the basis of an example embodiment in which a crane boom 2 forms a load block 4 ( figure 2 ). The boom 2 can be raised by means of a power drive in the form of a hydraulic working cylinder 6 ; more specifically, the boom 2 can pivot about a connection point 8 . The working cylinder 6 is a hydraulic cylinder that can be driven by a hydraulic system 10 that is only figure 2 symbolically shown in , see figure 2 , where only the control valve assembly is marked 12 and the hydraulic pump is marked 14. The hydraulic system 10 may, in particular, be of a design commonly used in working machines, and therefore need not be described in detail here.

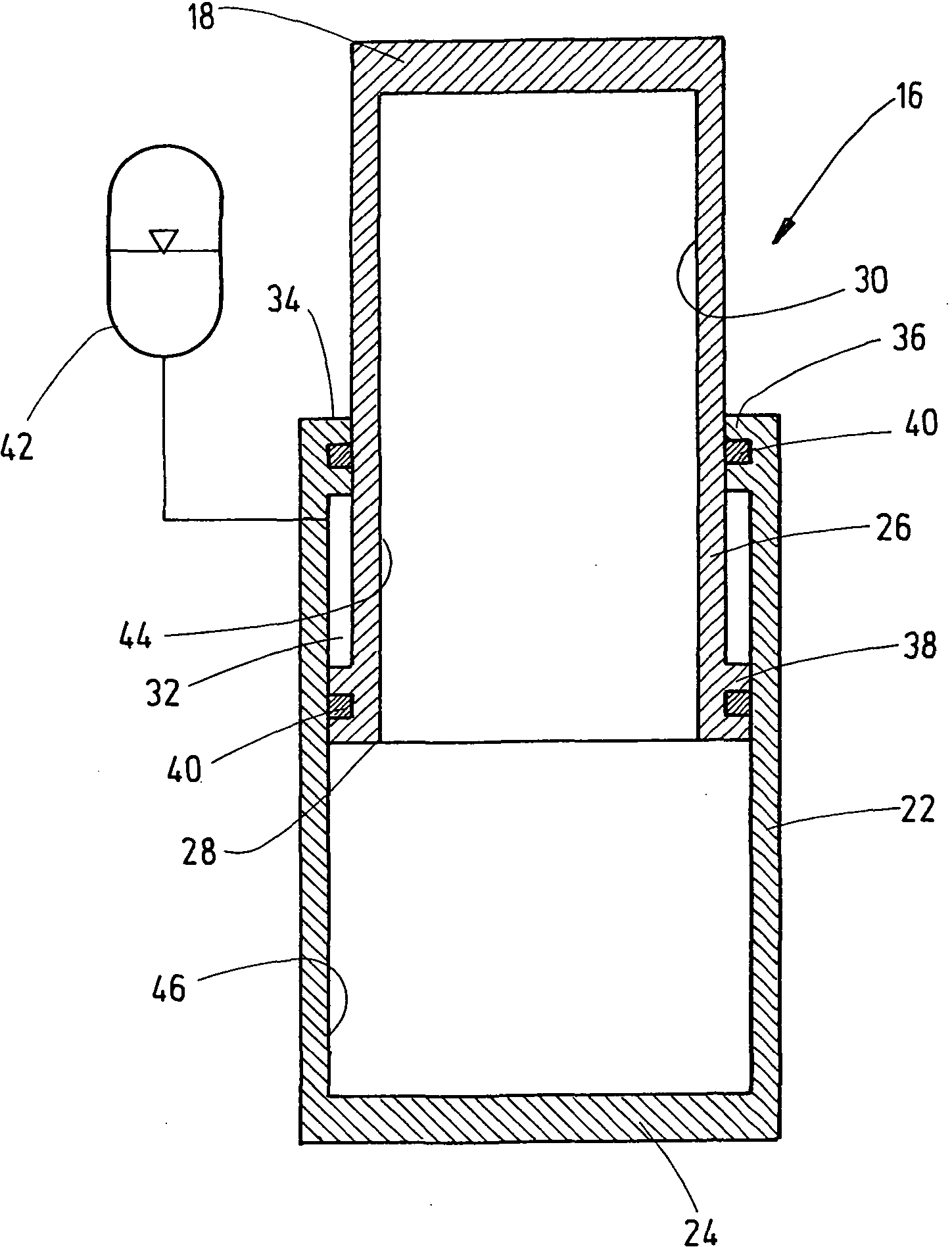

[0025] The accumulator cylinder 16 is mechanically shunted to the working cylinder 6 forming the power drive; that is, similar to the piston rod 20 of the working cylinder 6, the piston rod 18 of the accumulator cylinder 16 acts directly on the load block 4 (boom 2 )superior.

[0026] im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com