Device and method for cleaning via-hole surface of ceramic raw belt of stacked coil component

A technology of surface cleaning and laminated coils, applied in chemical instruments and methods, cleaning methods using tools, cleaning methods and utensils, etc., can solve problems such as poor hole filling effect, unreliable electrode connection of products, and electrode disconnection , to make up for the poor effect of hole filling, realize the automation of cleaning equipment, and reduce the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

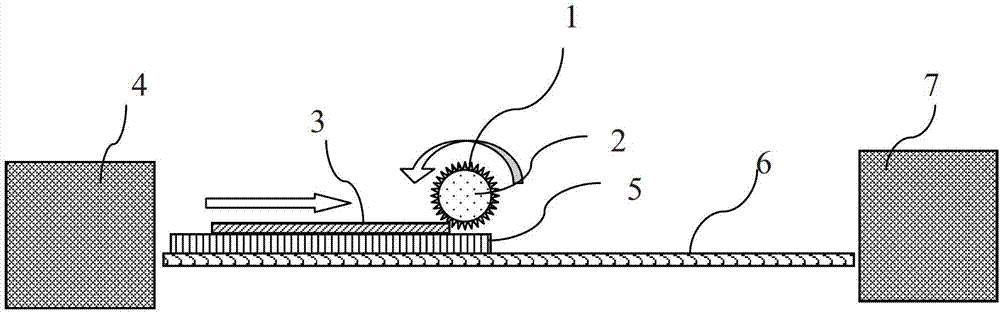

[0035] a kind of like Figure 1~3 The ceramic green tape through-hole surface cleaning device of the laminated coil components shown includes a ceramic green tape feeding part 4, a ceramic green tape unloading part 7, and a ceramic green tape feeding part 4 and a ceramic green tape unloading part. The running rail 6 between the components 7, the carrier 5 arranged on the running rail 6 for carrying the ceramic green tape 3, and the manipulator for placing the ceramic green tape 3 on the carrier 5 for carrying the ceramic green tape 3 ( figure 1 not shown in).

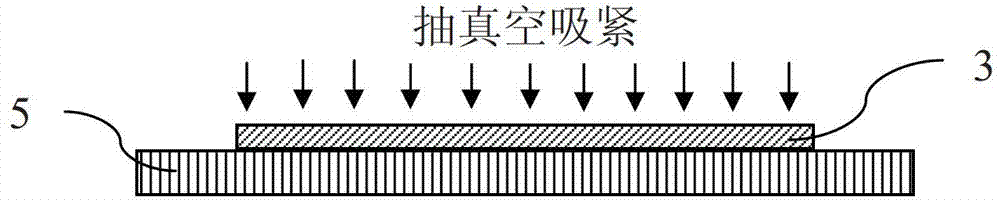

[0036] The stage 5 is driven by the power part and moves along the running guide rail 6 from the ceramic green tape feeding part 4 to the ceramic green tape unloading part 7. The ceramic green tape 3 is provided with through holes by laser or mechanical drilling method, and the ceramic green tape 3 Residual dust or debris adheres around the through holes on the surface. The carrier 5 is a carrier that includes a vacuu...

specific Embodiment approach 2

[0039] A method for cleaning the surface of a through-hole of a ceramic raw tape of a laminated coil component, which has the following steps in sequence:

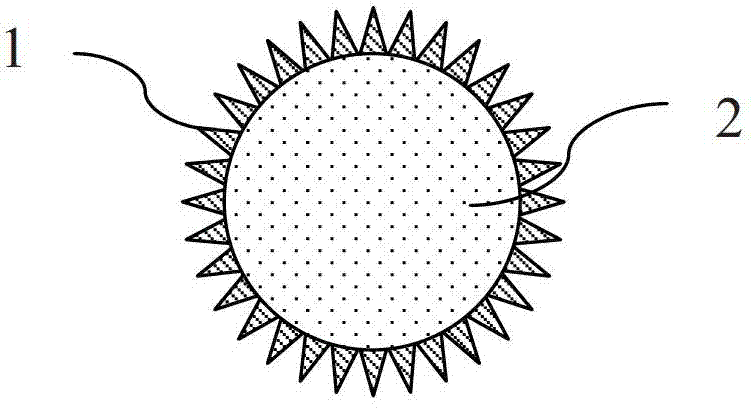

[0040] 1) Make a circular roller 2 with an adjustable brush 1. The size of the brush 1 is adjusted according to the size of the dust and the cleaning efficiency. The bristles of the brush 1 are adjustable in size. According to the size of the dust and the cleaning efficiency be adjusted;

[0041] 2) Assemble the circular roller 2 with the adjustable brush 1 on the top of the running guide rail 6 arranged between the ceramic raw tape loading part 4 and the ceramic green tape unloading part 7, and the running guide rail 6 is set There is a stage 5 including a vacuum assembly for carrying the ceramic green tape 3, the brush 1 is in contact with the surface of the ceramic green tape 3 carried by the stage 5, and the ceramic green tape 3 is provided with a through hole by laser or mechanical drilling method, Residual dust or d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com