Double-interface module electrical connection material and its preparation method and application

A technology of connecting materials and double interfaces, which is applied in the field of communication electronics, can solve the problems of low yield rate of finished products, low yield rate of products, antenna touch welding, etc., achieve the effect of reducing cost input, simple and easy preparation method, and improving yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An electrical connection material for a dual-interface module, which is a mixture of alloy solder paste and polymer microspheres that can expand in volume after heating, wherein the alloy solder paste is tin-lead paste, and the polymer microspheres are EXpancel DU (produced by Nouryon, Japan). The mixing mass ratio of the two is 20:0.1.

[0028] The preparation method of the electrical connection material of the double-interface module comprises the following steps:

[0029] First add volatile solvent toluene to the alloy solder paste to reduce the viscosity of the solder paste, then add polymer microspheres that can expand in volume after heating, and disperse at a high speed at a stirring speed of 3500r / min to obtain the dual-interface module Electrical connection material.

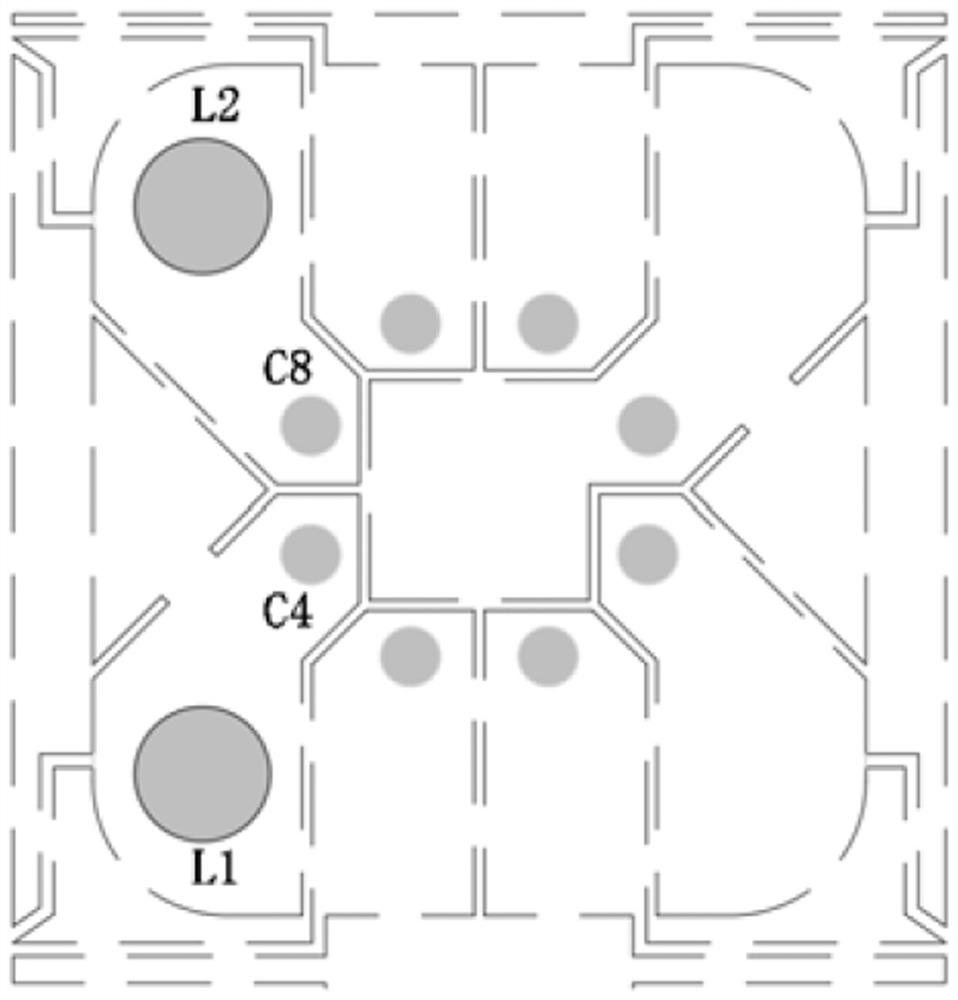

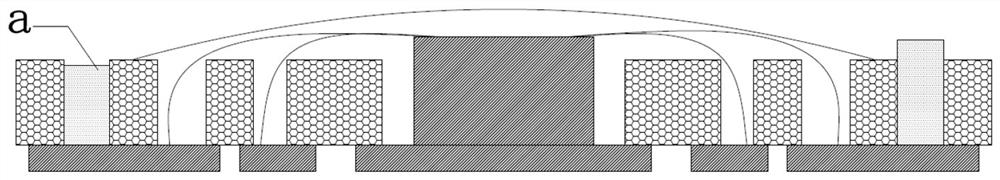

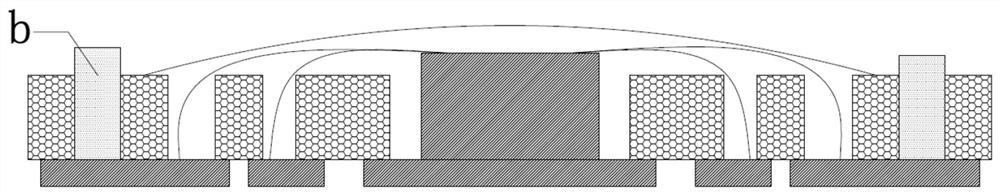

[0030] Remove the volatile solvent in the connection material, and screen-print the connection material on the module with the via holes L2 and L1 with a diameter of 2 mm and a hole depth of 90 ...

Embodiment 2

[0032] A dual-interface module electrical connection material, which is a mixture of alloy solder paste and polymer microspheres that can expand in volume after heating, wherein the alloy solder paste is tin-silver-copper solder paste, and the polymer microspheres are F-190D (produced by Matsumoto, Japan) , the mixing mass ratio of the two is 20:1.

[0033] The preparation method of the electrical connection material of the double-interface module comprises the following steps:

[0034] First add volatile solvent alcohol to the alloy solder paste to reduce the viscosity of the solder paste, then add polymer microspheres that can expand in volume after heating, and disperse at a high speed at a stirring speed of 2000r / min to obtain the dual-interface module Electrical connection material.

[0035] Remove the volatile solvent in the connection material, and screen-print the connection material on the module with the via holes L2 and L1 with a diameter of 2.5 mm and a hole depth...

Embodiment 3

[0037] An electrical connection material for a dual-interface module, which is a mixture of alloy solder paste and polymer microspheres that can expand in volume after heating, wherein the alloy solder paste is tin-lead paste, and the polymer microspheres are EXpancel DU (produced by Nouryon, Japan). The mixing mass ratio of the two is 1:1.

[0038] The preparation method of the electrical connection material of the double-interface module comprises the following steps:

[0039] The polymer microspheres capable of volume expansion after heating are added to the alloy solder paste, and dispersed at a high speed at a stirring speed of 6000 r / min to obtain the electrical connection material for the dual-interface module.

[0040] On the module with via holes L2 and L1 with a diameter of 3 mm and a hole depth of 150 microns, the above-mentioned connection material is silk-screened, and after reflow at 200° C., the thickness of the solder becomes 170 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com