Silicon micro machine inclination sensor and its manufacturing method

An inclination sensor, silicon micro-machine technology, applied in instruments, measuring inclination, measuring devices, etc., can solve the problems of weak anti-lateral coupling interference, large sensor power consumption, slow response, etc., to reduce the risk of signal disconnection , the effect of improving sensitivity and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

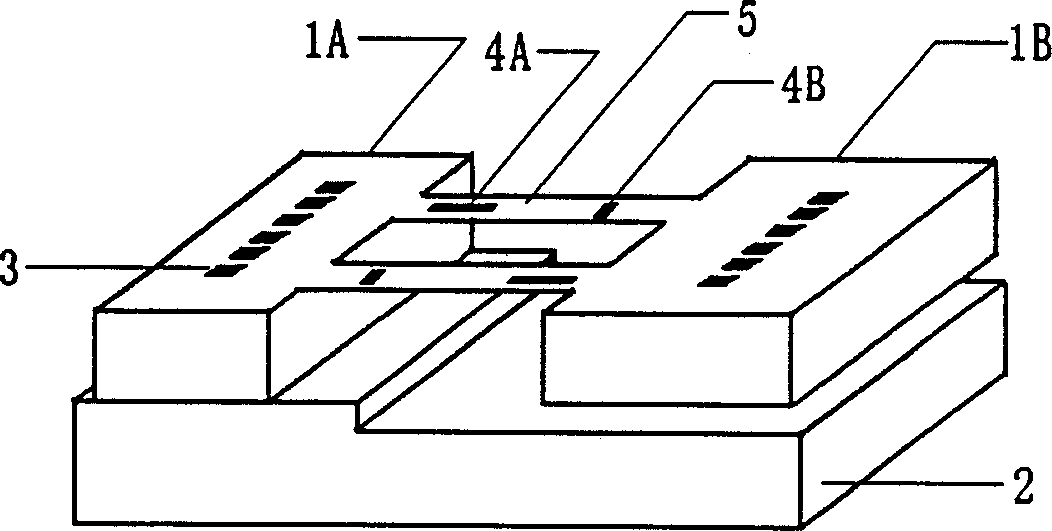

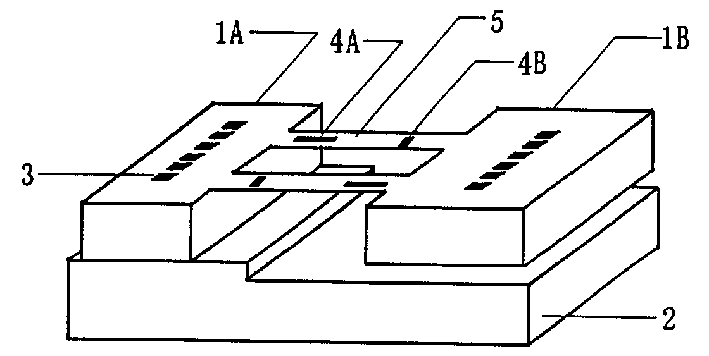

[0032] The silicon micromechanical inclination sensor consists of two silicon mass blocks 1A and 1B of different sizes, two parallel silicon strain beams 5 connecting them, and a glass substrate 2 with a step underneath. The height of the glass step is Equal to the maximum deformation of the silicon strain beam. Both the silicon mass 1A and the silicon mass 1B have electrodes 3 on their surfaces.

[0033] Two piezoresistors 4A and 4B, which are perpendicular to each other, are arranged at both ends of the silicon strain beam 5. The signals of the piezoresistors 4A and 4B can be output from the silicon mass at either end and installed on The four piezoresistors 4A and 4B on the two silicon strain beams 5 are cross-symmetrical.

[0034] Either one of the silicon mass 1A and the silicon mass 1B above the sensor can be sealed with the upper step of the glass substrate 2 below, and the glass substrate 2 is made of borosilicate glass with a thermal expansion coefficient closer to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com