Integrated finish machining method for inner profile and corner of pocket

A technology of groove features and corners, applied in the field of machining of mechanical parts, can solve the problems of tool chipping, uneven force on the tool, tool vibration, etc., to improve processing efficiency, improve processing quality, and avoid tool marks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the drawings and embodiments.

[0046] Such as Figure 1-6 Shown.

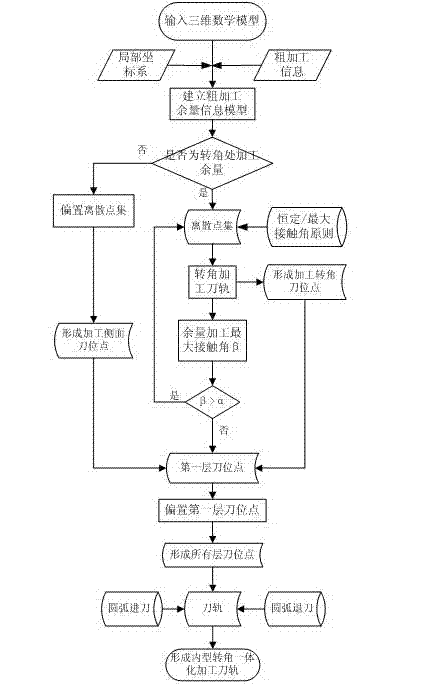

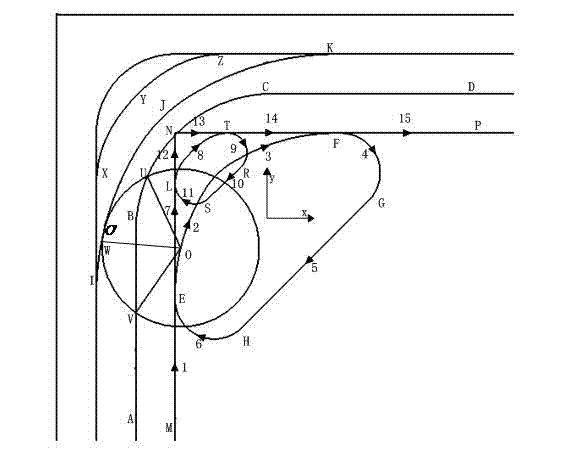

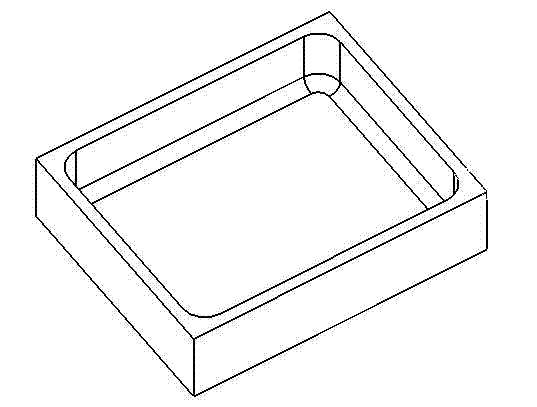

[0047] Attached figure 2 with image 3 It is a schematic diagram of the groove characteristics and processing paths of typical aircraft structural parts, as detailed below.

[0048] An integrated finishing method for the inner corner of the groove feature, it should first use the existing technology to image 3 The three-dimensional mathematical model of the part shown is input into the computer and the rough machining process NC program is generated according to the existing machining process, and then the generated rough machining process program is stored in the computer for calling, this embodiment and all of the present invention The starting point is all under the premise that the rough machining process information has been generated. The integrated processing steps of the entire inner shape and corner are (such as figure 1 Show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com