Die-cutting roller circumference aligning device

A technology of alignment device and die-cutting roll, applied in metal processing and other directions, can solve the problems of complex, complex structure and large adjustable range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

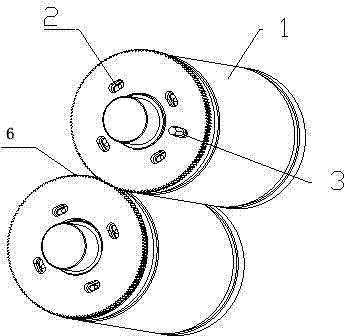

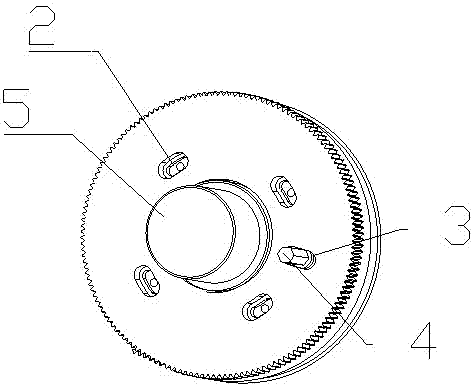

[0023] according to Figure 1-2 , the die-cutting roller circumferential alignment device, including the upper and lower rollers 1, the shoulder 5 located at the end of the roller 1, is characterized in that: it also includes an adjustable gear 6 fixed on the side of the upper roller; the adjustable gear 6 is provided with a sinker fixed The waist-shaped hole 2 of the screw and the adjustment hole 3 of the eccentric adjustment block 4 are arranged. The waist hole 2 is a quadrilateral with two opposite sides extending outwards (such as figure 2 ), rectangle or polygon. The adjustment hole 3 is quadrilateral, rectangular or polygonal in shape with two opposite sides extending outward. The circumferential alignment device of the die-cutting roller also includes a gear fixed on the side of the lower roller; the gear is provided with four waist-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com