Labor-saving electric train

A train and electric technology, applied in the field of labor-saving diesel generators, can solve problems such as energy consumption, damage to the natural environment, and labor-saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

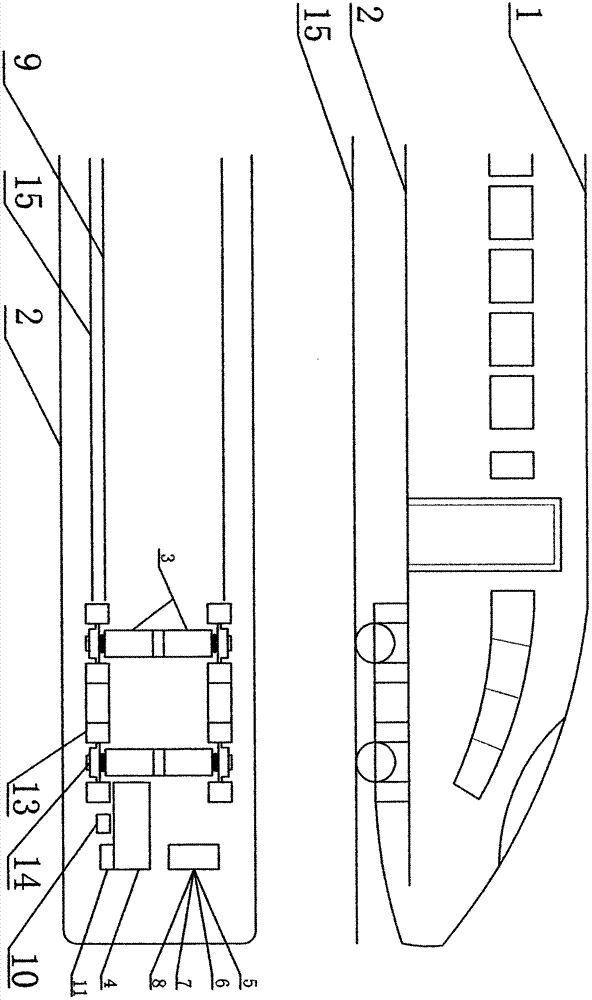

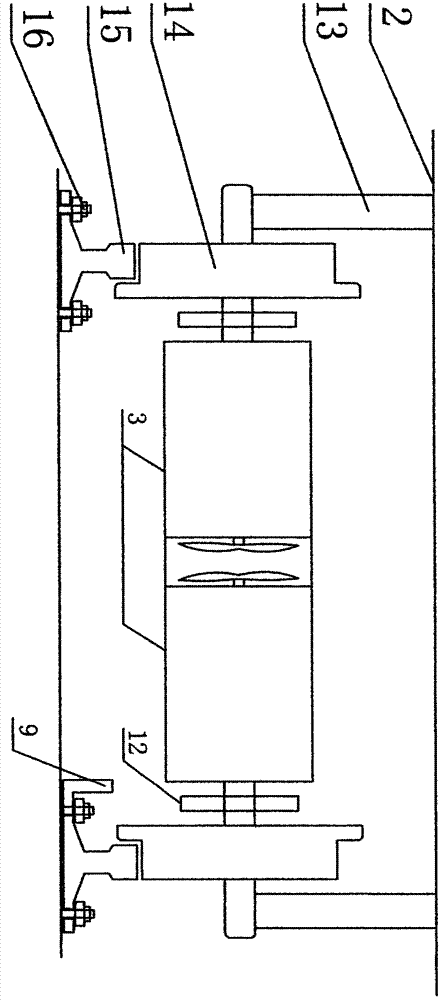

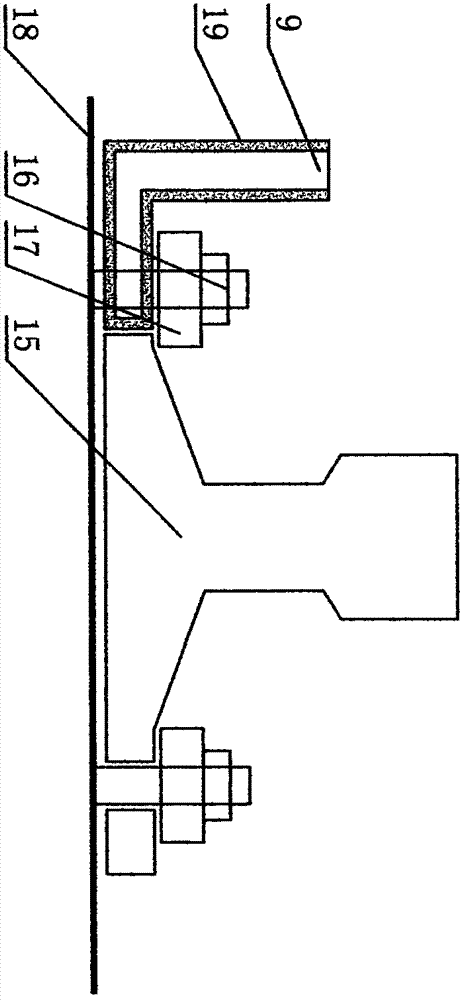

[0038] Such as figure 1 , 2 , shown in 3, a kind of labor-saving electric train (power dispersion type), it comprises car body 1, chassis 2, labor-saving electric motor 3, labor-saving electric generator 4, computer 5, display 6, frequency converter 7, sensor 8, wire 9 (live wire), brush 10, transformer 11, brake, brake disc 12, shock absorber 13, wheel 14, rail 15 (ground wire), cable, lamp, instrument, meter, etc. Such as figure 1 Shown: computer 5 (operating system), display 6, frequency converter 7, sensor 8, brake, transformer 11, labor-saving electric generator 4 are housed in the locomotive; , brake disc 12, shock absorber 13 etc.; also be equipped with four labor-saving electric motors 3 and wheel 14, brake disc 12, shock absorber 13 etc. at the rear position of front chassis 2; Four labor-saving motors 3 and wheels 14 are respectively housed (eight labor-saving motors 3 and wheels 14 are housed in each joint car phase chassis), brake disc 12, shock absorber 13 etc....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com