Buffering and dividing device on transition platform of steel pipe production line

A material distribution device and production line technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problem of being easily scratched, and achieve the effect of reducing the probability of scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

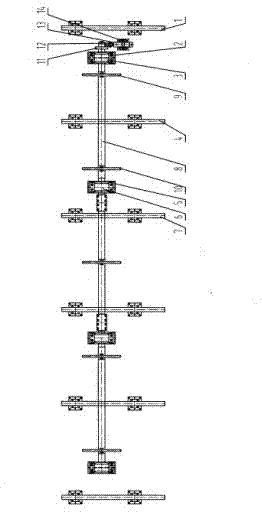

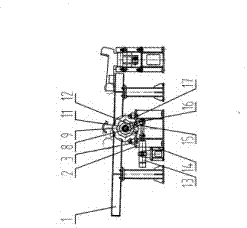

[0015] A buffer material distributing device on a transition stand of a steel pipe production line, comprising a first ramp 1, a second ramp 4 and a third ramp 7 arranged parallel to each other on the transition stand. The first distribution device base 2 is arranged between the bar 1 and the second oblique grate bar 4, and the first bearing seat 3 is fixedly arranged on the first distributing device base 2. Between the second oblique grate bar 4 and the third oblique grate A second distribution device base 5 is arranged between the grating bars 7, a second bearing seat 6 is fixedly arranged on the second distribution device base 5, and a distribution device is arranged between the first bearing seat 3 and the second bearing seat 6. The material shaft 8 is fixedly provided with a first material distribution plate 9 and a second material distribution plate 10 respectively on the material distribution shaft 8, and a ratchet 11 is fixedly pierced on the right end shaft of the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com