Preparation method of rosin glycerol ester

A technology of rosin glyceride and glycerin, which is applied in the field of deep processing of rosin, can solve the problems of no major progress in product types and preparation methods, slow reaction, long time consumption, etc., and achieves the effects of high quality, stable reaction, and improved production and equipment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

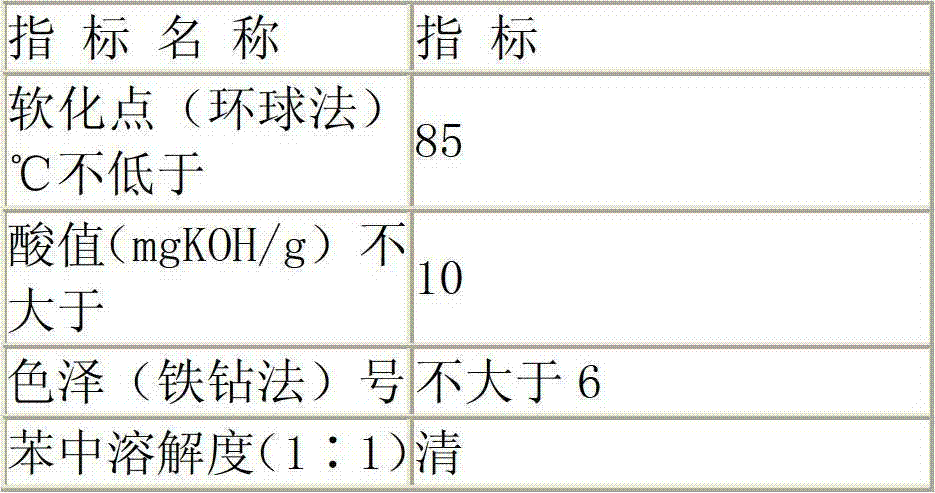

[0011] In the preparation method of rosin glyceride of the present invention, the reaction speed is accelerated by 3-5 times by enlarging the catalyst, and the reaction becomes stable and easy to control through the method of enriching polyols, so that the production period is greatly shortened, and the production and equipment efficiency is high In order to improve, the production cost is reduced; and products with light color and high quality are obtained.

[0012] The preparation method of rosin glycerin ester of the present invention comprises the reaction of rosin and glycerin under a catalyst, and high-temperature vacuum removal of remaining glycerin; it is characterized in that: by weight, the material ratio is 100 parts of rosin, not less than 50 parts of glycerin, and 1.5 parts of zinc oxide -2.6 parts of catalyzer, its technique comprises the following steps:

[0013] 60-70 parts of rosin are heated and melted, and the temperature is raised to 250°C,

[0014] Add 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com