A gear unit and a method for controlling a lubrication pump of a gear unit

A gear unit and lubricating pump technology, applied in gear lubrication/cooling, engine lubrication, transmission control, etc., can solve the problem of long duration of cold start process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

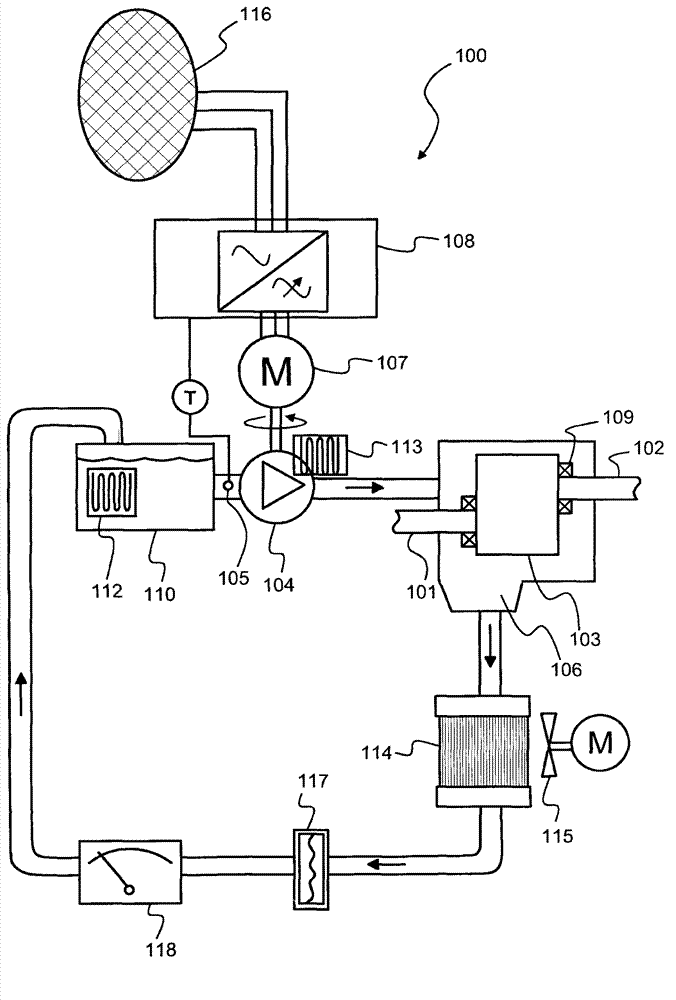

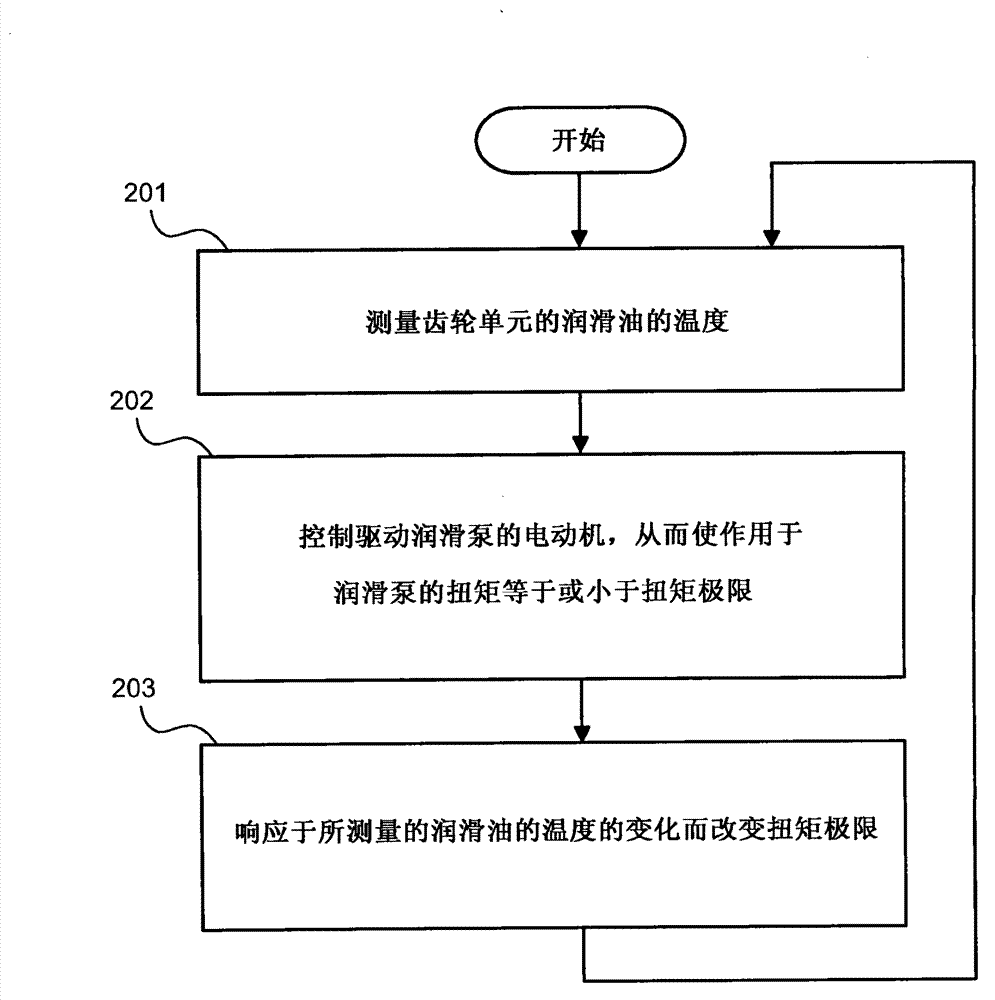

[0032] figure 1 A schematic diagram of a gear unit 100 according to an advantageous exemplary embodiment of the invention is shown. The gear unit comprises a first shaft 101 and a second shaft 102 for connection to an external mechanical system. The external mechanical system may for example but not necessarily comprise a wind turbine connectable to the shaft 101 and a generator connectable to the shaft 102 ie the gear unit can eg be a gear unit suitable for wind energy applications. The gear unit comprises at least one gear stage 103 between shafts 101 and 102 . The at least one gear stage may eg comprise one or more planetary gear stages, one or more spur gear stages and / or one or more bevel gear stages, or a combination of the aforementioned kinds of gear stages. The gear unit comprises a lubricating pump 104 for circulating lubricating oil through at least one gear stage of the gear unit and bearings 109 . The lubricating pump can be, for example, a gear pump. exist f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com