Automatic detecting machine for air tightness of pipe

A pipeline gas and detection machine technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, can solve the problems of long time-consuming, misjudgment of pipeline wall, and easy leakage of micropores, so as to reduce work intensity and Difficulty, reduce production time, improve the effect of inspection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

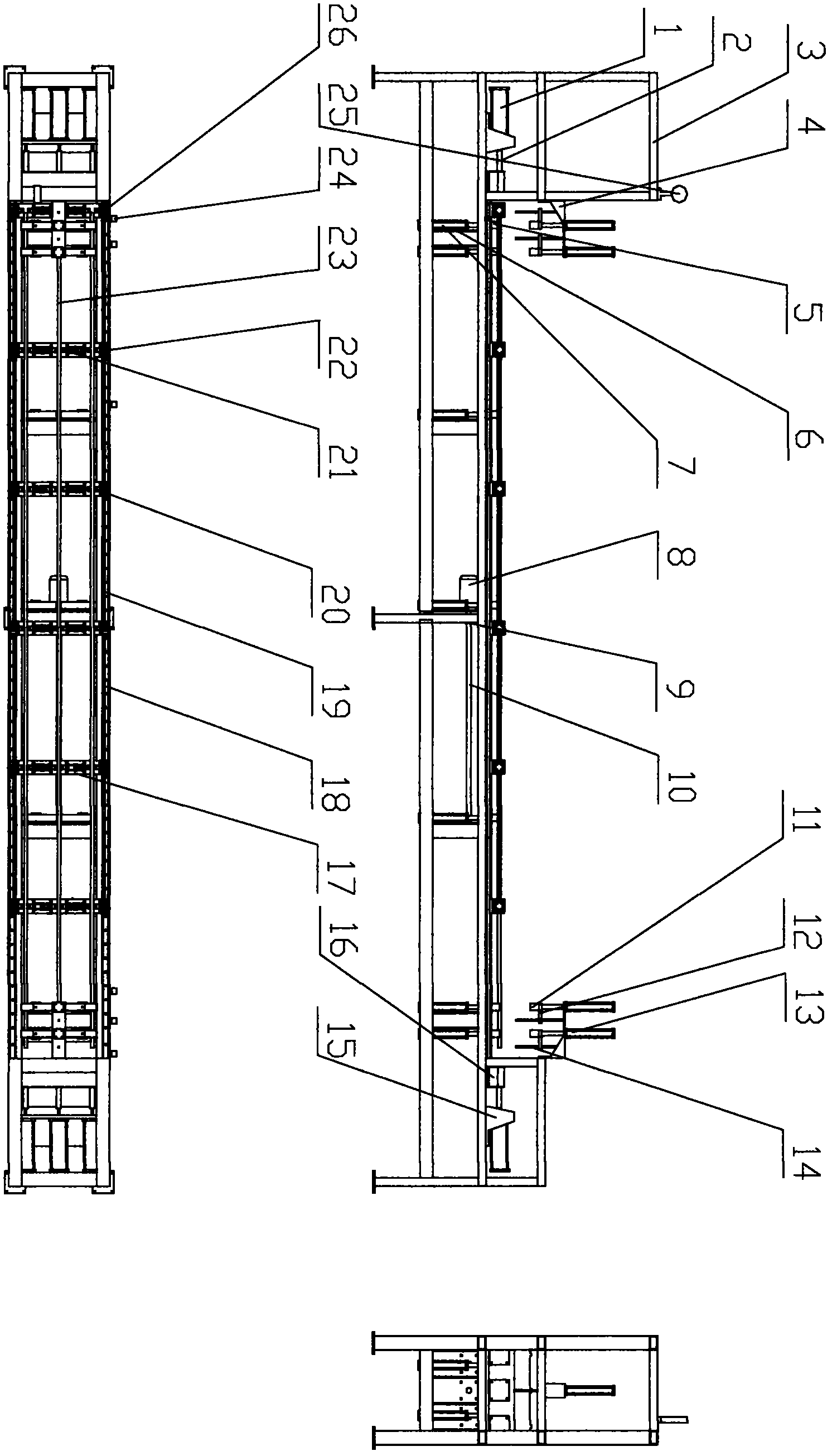

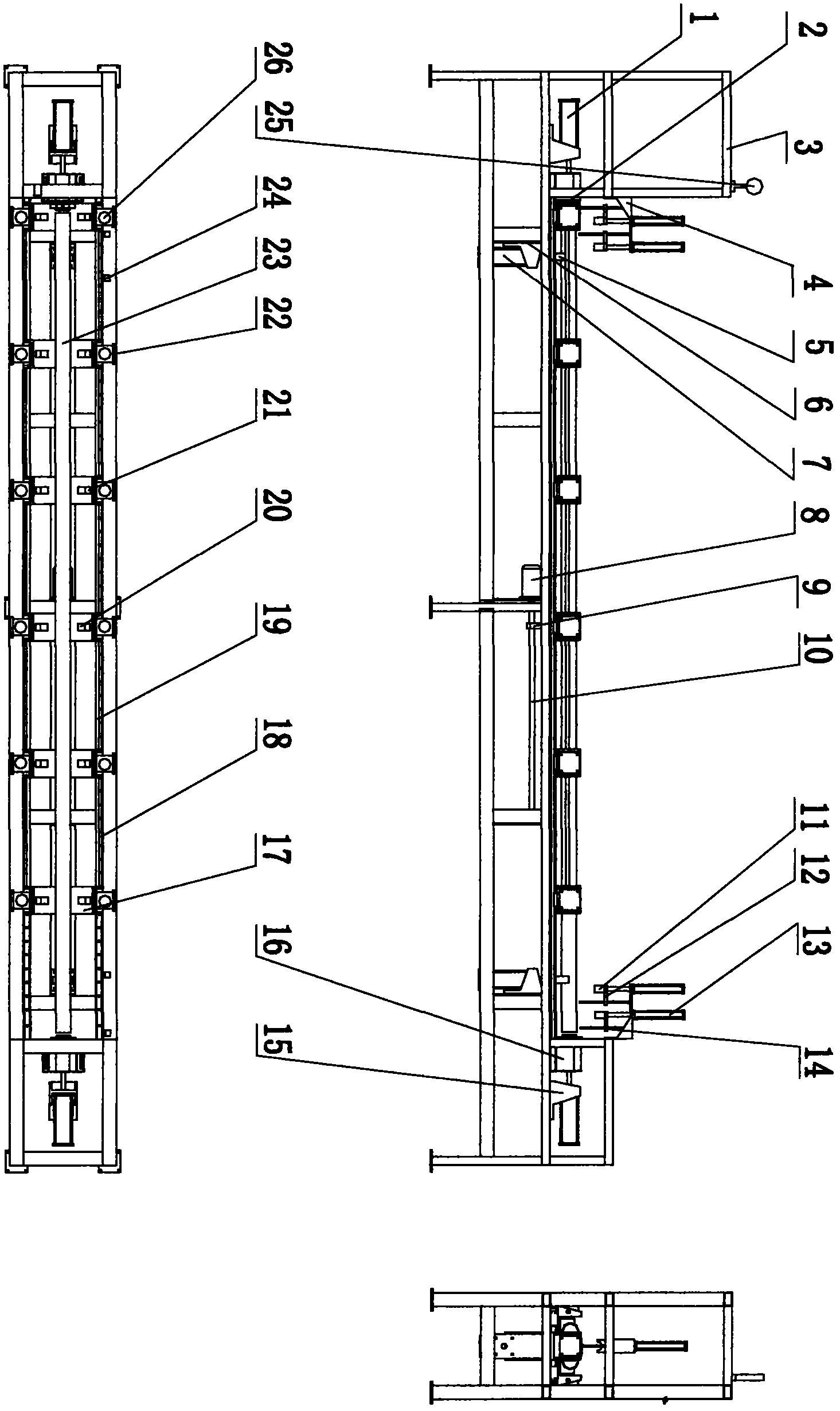

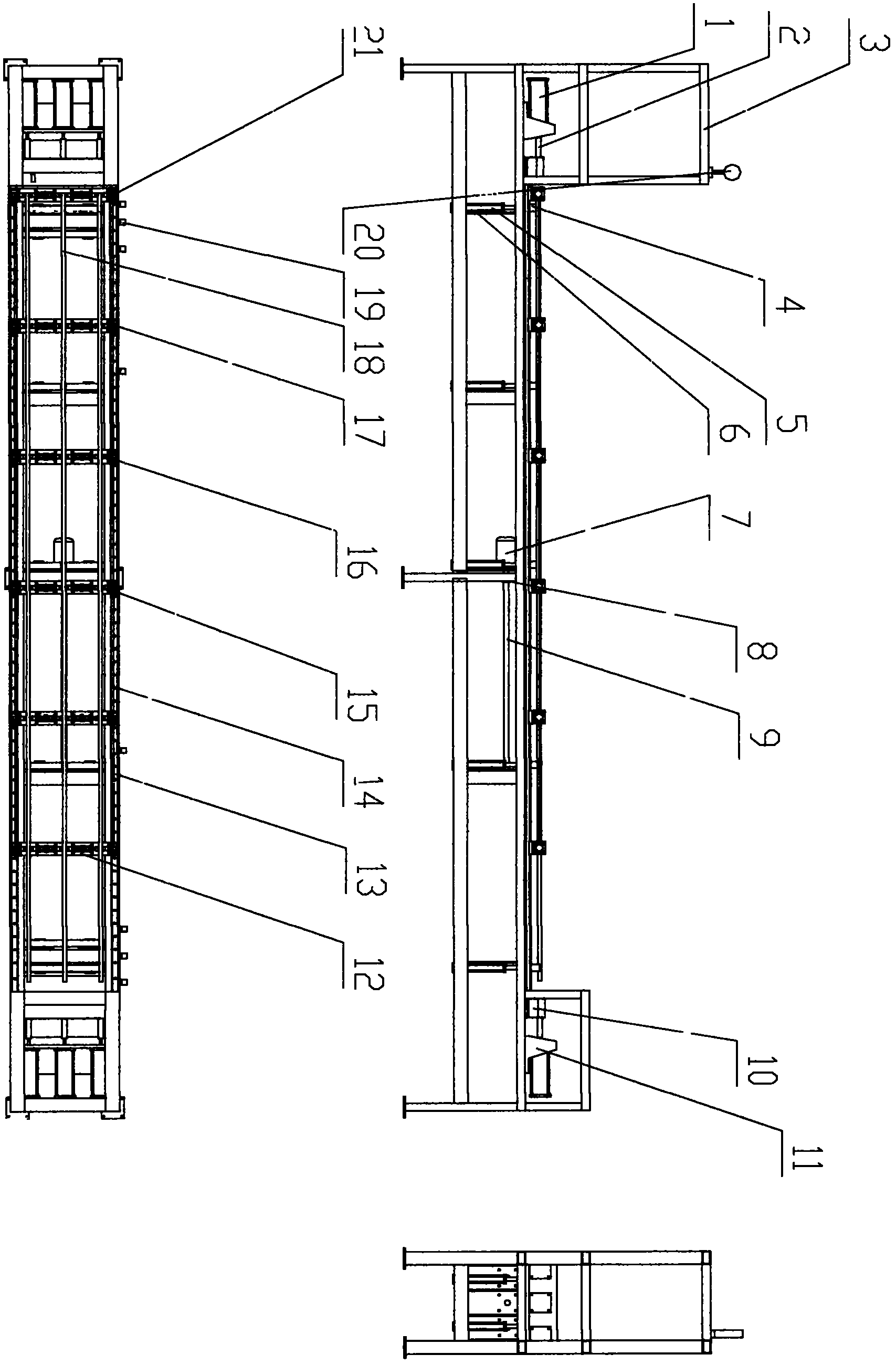

[0044] refer to figure 1 Shown, pipeline airtightness automatic detection machine of the present invention, it comprises 1, compresses plug power unit (containing cylinder, hydraulic cylinder, electric cylinder, motor etc.); 2, compresses plug; 3, frame; 4. Pipe compression support; 5. Pipe support seat; 6. Supporting power device fixed plate; 7. Supporting power device (including cylinder, hydraulic cylinder, electric cylinder, motor, etc.); 8. Mobile power device (including cylinder, hydraulic cylinder, electric cylinder, motor, etc.); 9. connection plate; 10. transmission rod; 11. compression template; 12. compression connection plate; 13. pipeline compression power device (including cylinder, hydraulic cylinder, electric cylinder, Motor, etc.); 14. Guide rod 15. Fixing seat of power device for pressing plug; 16. Guide seat; 17. Moving seat for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com