Method for testing performance of mold pressing premixed material

A test method and premix technology, applied in the direction of removing certain components and weighing, can solve the problems of limited test items, low test accuracy, and high test cost, so as to improve test items, ensure reliability, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

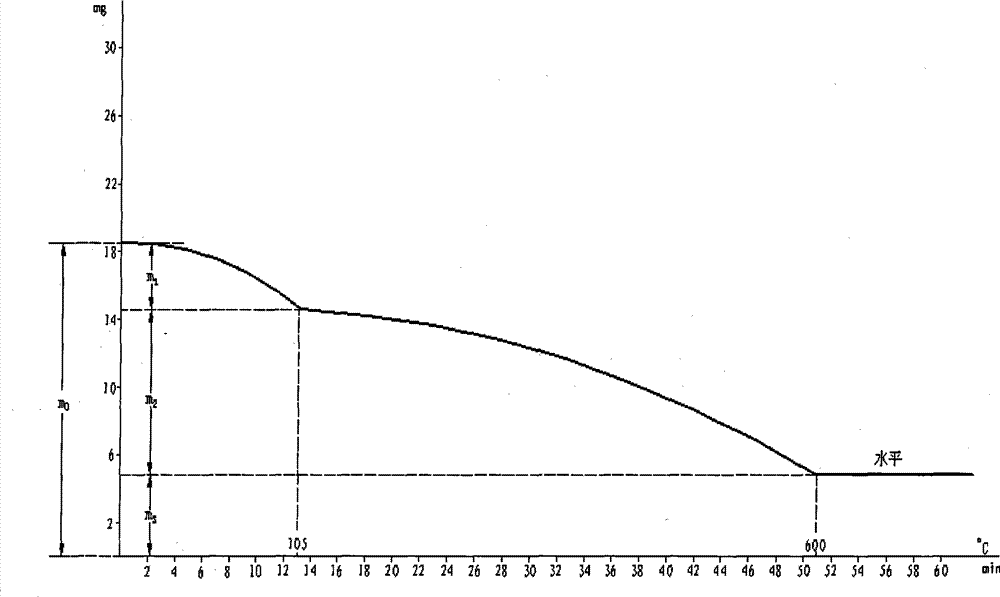

[0027] see figure 1 .

[0028] The present invention adopts thermogravimetric analysis and chemical combined testing method (abbreviated as "thermal-chemical method"). The thermal-chemical method is an efficient and comprehensive test method combining physics and chemistry, which includes the thermogravimetric analysis stage and the chemical test stage. This test method makes up for the shortcomings of the traditional test method and improves the performance test items of the molded premix. Specifically, a thermogravimetric instrument is used to test the program section of heating and heat preservation at different temperature sections, and read out the mass reduction of each stage from the thermogravimetric analysis curve of the test, and then use the mass reduction of each stage Calculate the volatile content, resin content, and fiber content by comparing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com