Device and method for measuring rock core-formation water-CO2 wettability change

A formation water and wettability technology, applied in the fields of development and oil and gas field exploration, can solve the problems of not overcoming the influence of test accuracy, inaccurate measurement methods, etc., to optimize the design of the mine field, save the disassembly instrument, and reduce the error. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

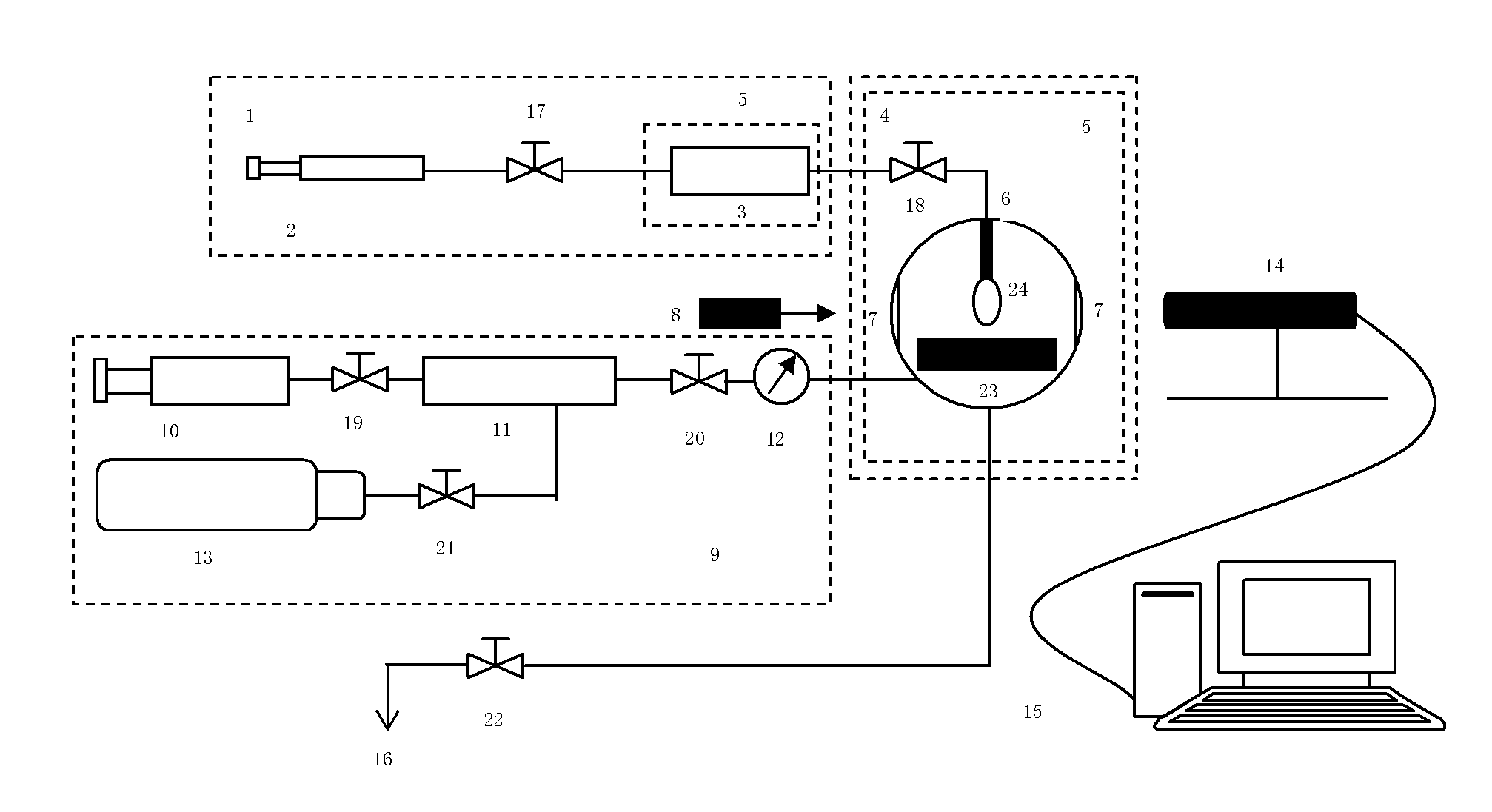

Method used

Image

Examples

specific Embodiment

[0049] A specific embodiment of the present invention is as follows:

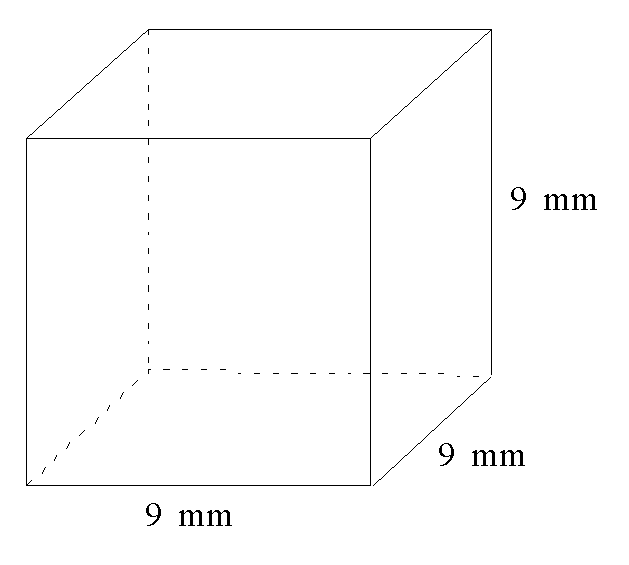

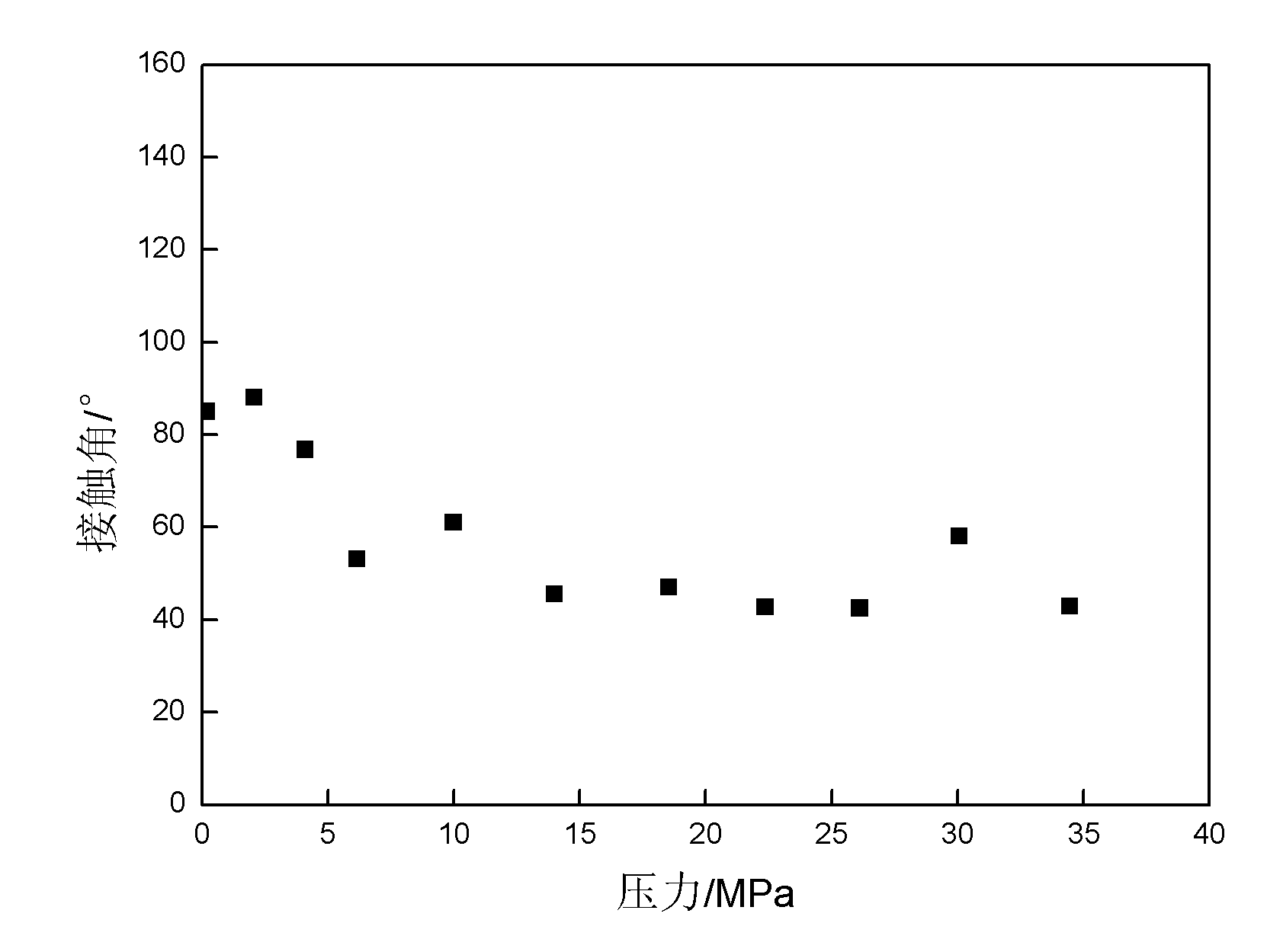

[0050] The formation water salinity of an oilfield is 14224.2mg / L, and the test core samples used are as follows: figure 2 As shown in the figure, the formation temperature of this oilfield is 97.53 °C, and different CO 2 Core under pressure - formation water - CO 2 Contact angle.

[0051] Utilize the inventive method to carry out experiment, and concrete steps are as follows:

[0052] Instrument installation steps:

[0053] (1) Cut the core into a specified shape, and polish the surface very smooth, such as figure 2 Because the entrance of the high temperature and autoclave is very small, only the core can be cut into small pieces before it can be put in. At the same time, the sample should not be too thin during the wettability test. You can choose a small cube, such as 9mm×9mm×9mm, etc.;

[0054] (2) place the cut core on the platform in the high temperature autoclave, and adjust the position to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com