Athermal lens

A heat-absorbing difference and lens technology, applied in the optical field, can solve problems such as aiming error, high adjustment accuracy requirements, increase system size and weight, etc., and achieve the effects of cost reduction, simple assembly, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

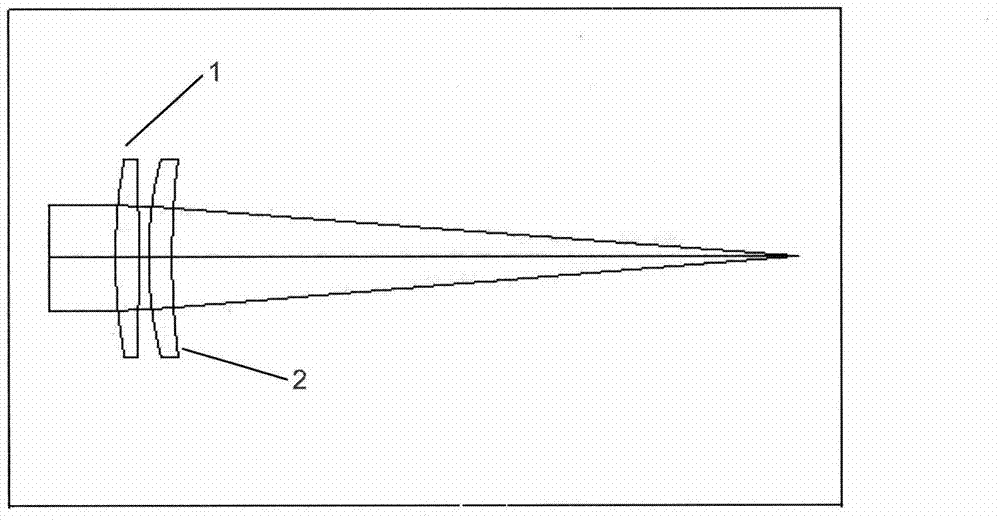

[0008] Such as figure 1 As shown, the present invention consists of lenses 1, 2 of different materials. The working principle of the invention is to use two lenses of different materials to eliminate thermal deformation of the laser.

[0009] The specific principle is: when the laser is irradiated on the lens, the thermal expansion of the lens increases the focal length, which affects the optical performance. At this time, lenses of two different materials are used, and the refractive index of the two materials will be affected by the temperature, which will cause the refractive index to decrease. Through scientific calculation, the focal length reduced by the refractive index change and the focal length increased by thermal deformation can be offset to keep the original focal length unchanged.

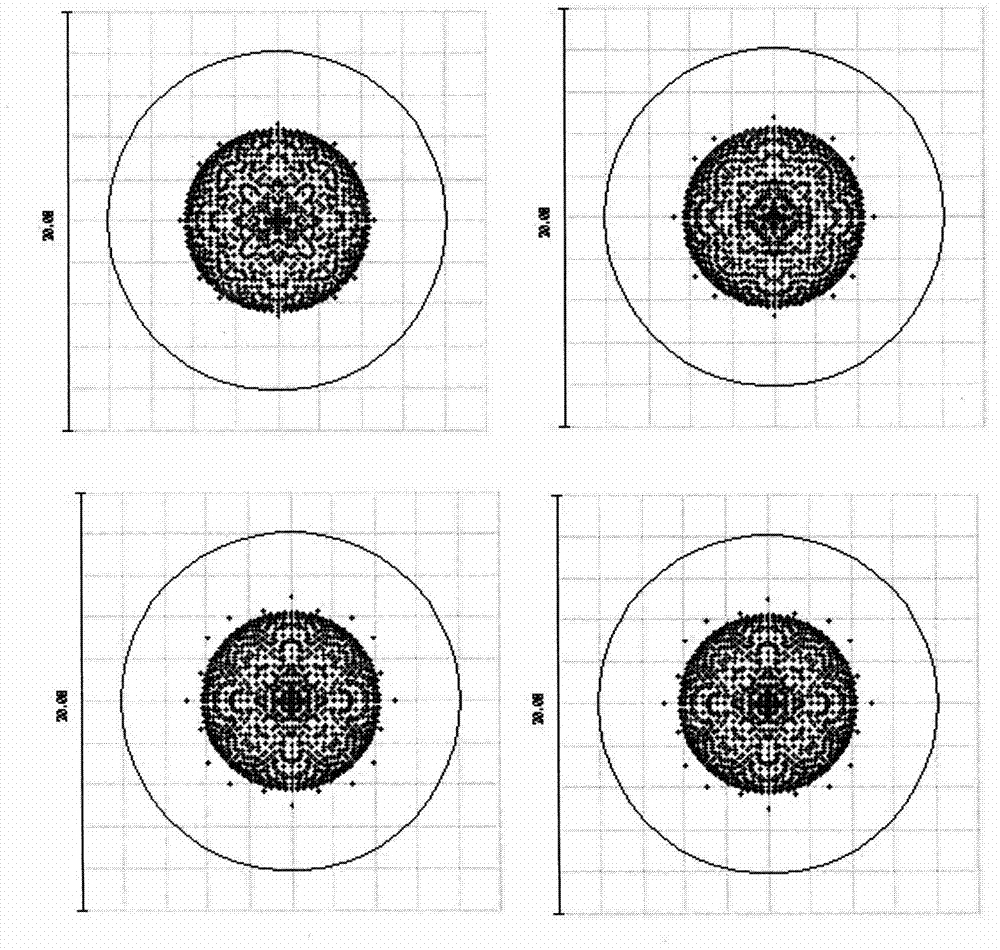

[0010] figure 2 It is a schematic diagram of the light spots of the present invention at different temperatures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com