Novel liquid crystal module structure

A liquid crystal module, a new type of technology, applied in lighting devices, optics, instruments, etc., can solve the problems of cumbersome assembly process, time-consuming and laborious, and achieve the effects of quick installation, reduced labor intensity, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

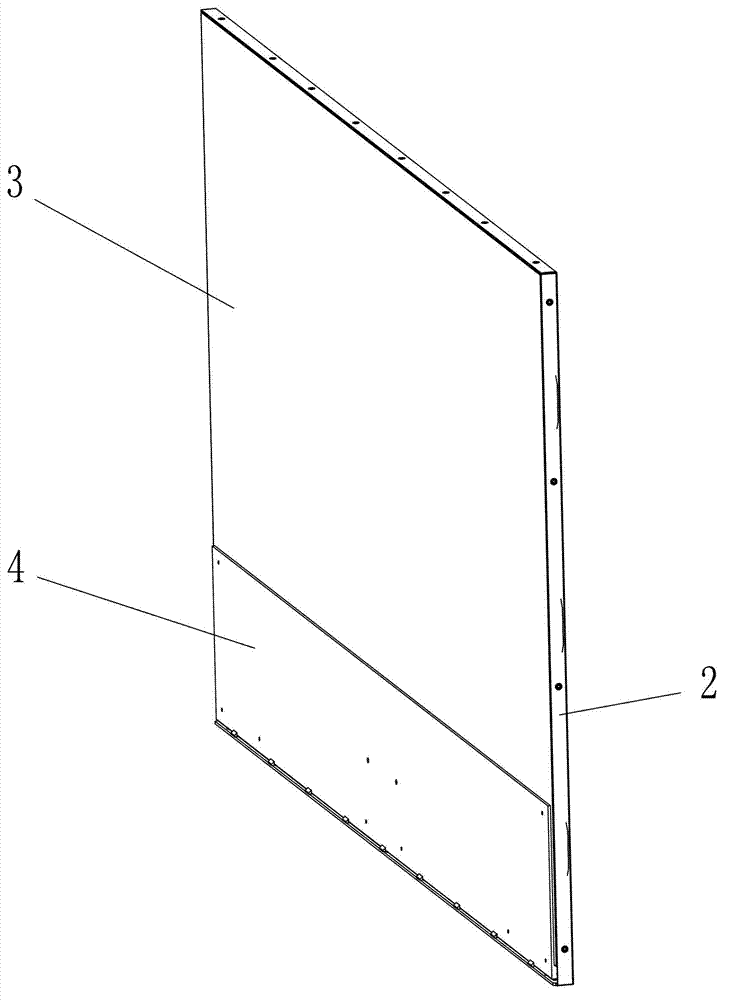

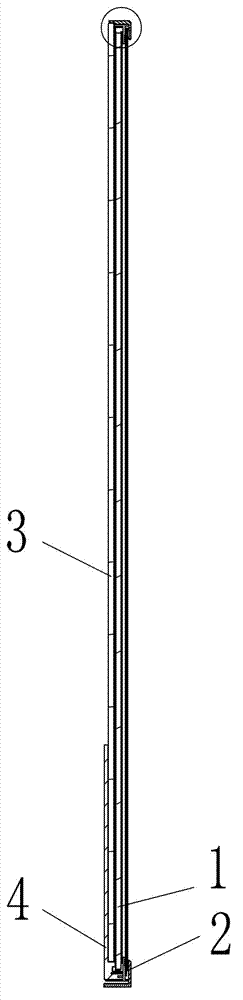

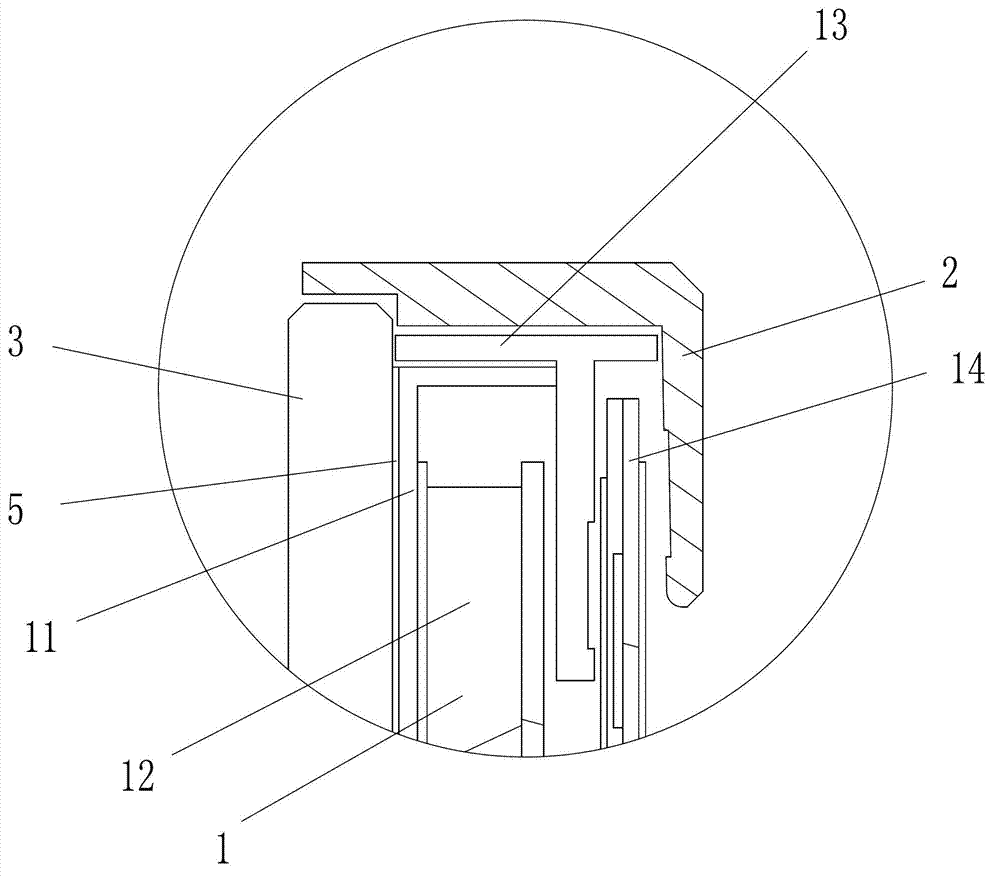

[0018] Example: as Figure 1 to Figure 4 As shown, a new type of liquid crystal module structure includes a backlight module 1, a front case 2 and a back plate 3, the back plate 3 is a glass back plate, the glass back plate 3 and the metal frame 11 of the liquid crystal module 1 Adhesive and fixed, the front case 2 covers the outer periphery of the liquid crystal module 1, and the side of the front case 2 and the outer periphery of the metal frame 11 are screwed and fixed by screws, and the plastic frame 13 of the liquid crystal module 1 is provided with screws for screws For the through holes, the side edges of the front shell 2 are screwed and fixed to the metal frame 11 through the holes of the plastic frame 13 through screws. The bottom of the rear side of the back plate 3 is glued and fixed with a heat sink 4 .

[0019] The above-mentioned metal frame 11 and the heat dissipation plate 4 can be attached to the back plate by using glue, tape or other adhesives 5 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com