A kind of anti-lock braking system automobile cable and its manufacturing method

A manufacturing method and brake system technology, applied in the direction of cable/conductor manufacturing, insulated cables, bendable cables, etc., can solve the problems of poor roundness of appearance, prone to hydrolysis, hard cable material, etc., to ensure matt, Guarantee the effect of stability and roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

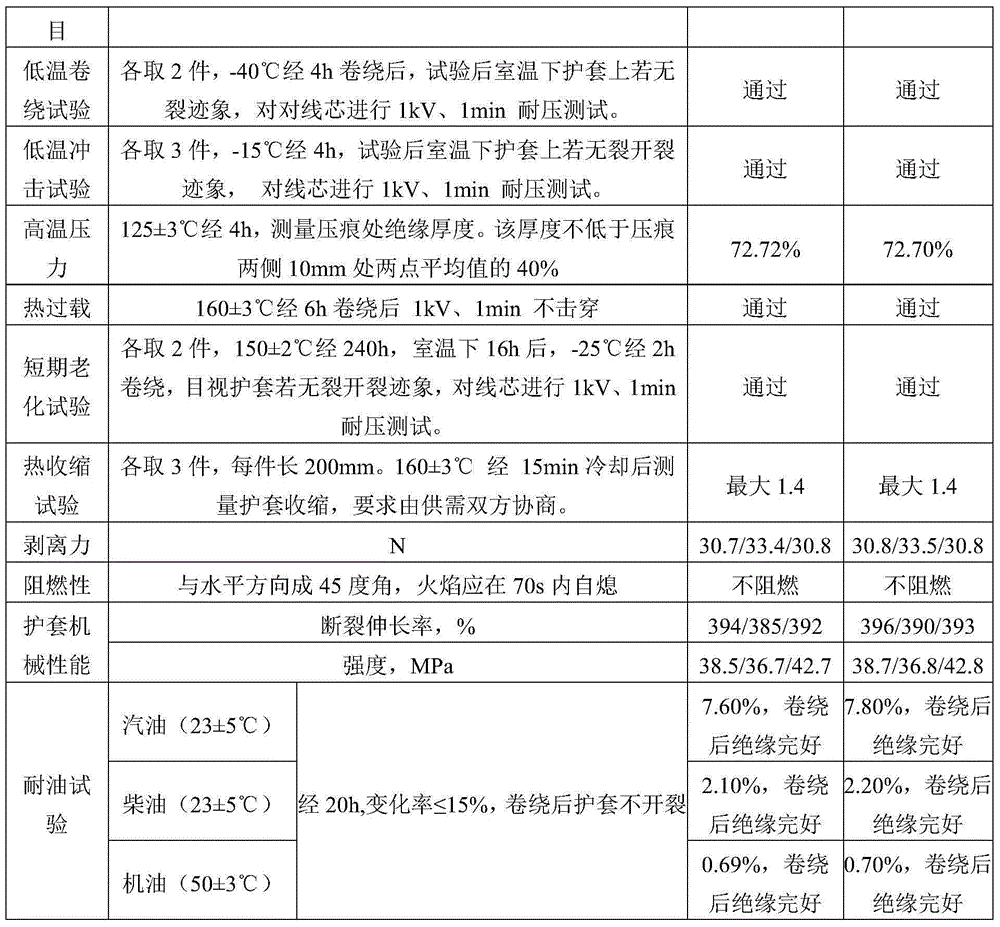

Embodiment 1

[0045] A method for manufacturing an anti-lock brake system automotive cable, comprising the steps of:

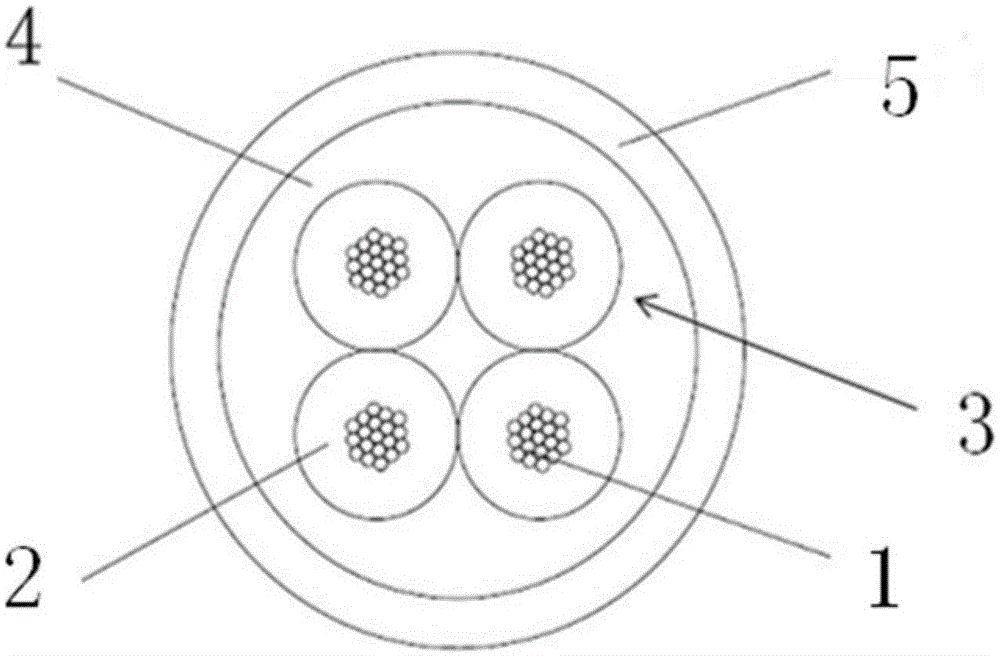

[0046] (1) Preheat the stranded conductor 1 to 90°C, extrude thermoplastic elastomer on the stranded conductor 1 with a 45-type extruder to form an insulating layer 2 with a thickness of 0.32mm, and directly water-cool it. The cooling water temperature is kept below 30°C to obtain the insulated wire core 3; among them, the stranded conductor 1 is formed by twisting 64 annealed annealed copper wires with a single wire diameter of 0.1 mm, and the cross-sectional area of the stranded conductor 1 is 0.50 mm 2 ;The extruding temperature is 160°C, 170°C, 175°C, 180°C and 175°C from zone 1 to zone 5 respectively. The ratio is 22:1, the screw compression ratio is 3:1, and the rotating speed of the screw is 15rpm;

[0047](2) Set the semi-extrusion die on the die head of the 45-type extruder, and double-layer extrude the polyether thermoplastic polyurethane on the 4 insulated wi...

Embodiment 2

[0050] A method for manufacturing an anti-lock brake system automotive cable, comprising the steps of:

[0051] (1) Preheat the stranded conductor 1 to 120°C, use a 45-type extruder to extrude thermoplastic elastomer on the stranded conductor 1 to form an insulating layer 2 with a thickness of 0.20 mm, and directly water-cool it. The cooling water temperature is kept below 30°C to obtain the insulated wire core 3; among them, the stranded conductor 1 is formed by twisting 128 annealed annealed copper wires with a diameter of 0.1mm, and the cross-sectional area of the stranded conductor 1 is 1mm 2 ;The extruding temperature is 160°C, 170°C, 175°C, 180°C and 175°C from zone 1 to zone 5 respectively. The ratio is 32:1, the screw compression ratio is 3:1, and the rotating speed of the screw is 50rpm;

[0052] (2) Set the semi-extrusion die on the die head of the 45-type extruder, and double-layer extrude polyether thermoplastic polyurethane on 2 or 7 insulated wire cores 3 at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com