Jointing metal tool and jointing method for composite graphene nano material wires

A technology of nano-materials and connection fittings, applied in the direction of conductive connection, connection, cable joints, etc., can solve the problems of less research on connection fittings, achieve stable and reliable construction technology, effective grip, and ensure the effect of power transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with example the present invention is described in detail.

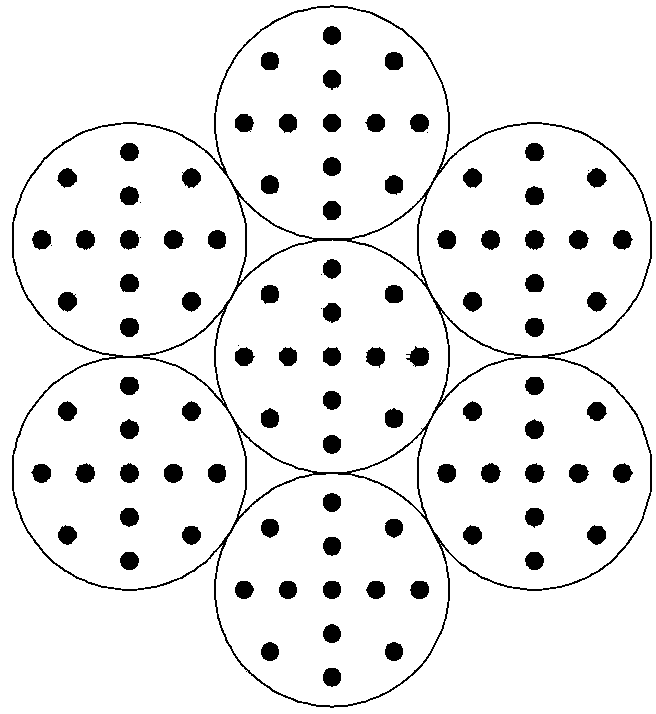

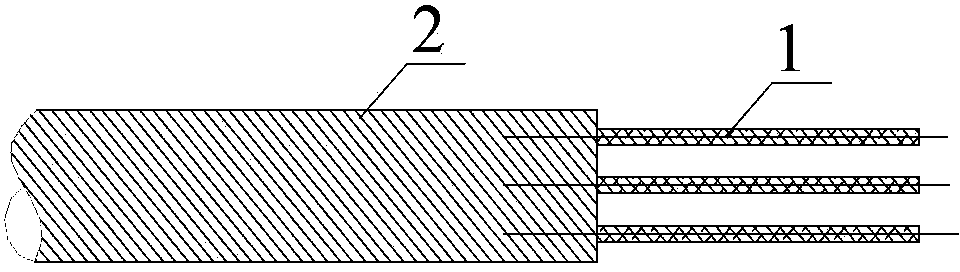

[0042] The structural type of the composite graphene nanomaterial wire is as follows figure 1 As shown, the wire includes a graphene rod 1 and a composite material 2, the graphene nanomaterial is used as a conductive part, the composite material 2 is mainly used as a load-bearing part of the wire, and the graphene rod 1 and the composite material 2 are composited into a wire. The circular cross-section of the wire is supported by composite materials, which are mainly used as the load-bearing function of the wire. Composite materials such as carbon fiber that can meet the requirements of wire manufacturing and transportation can be selected. The diameter and number of composite graphene materials are designed according to the design transmission capacity of the line and the operation requirements of the line.

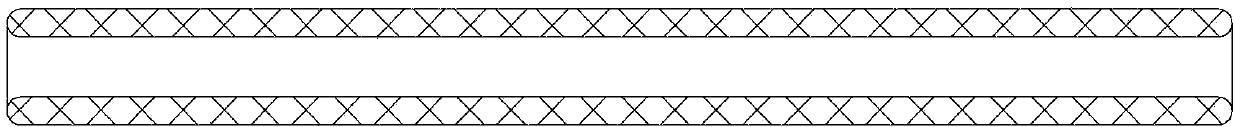

[0043] The splicing hardware includes a graphene splicing tube 3 and an aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com