Double-stator permanent magnetic direct drive generator and assembly method thereof

A permanent magnet direct drive and generator technology, which is applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve the problems of difficult assembly process and large volume, and achieve the effect of convenient transportation and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical problem to be solved by the present invention is to provide a dual-stator permanent magnet direct drive wind generator and its assembling process method that can greatly reduce the volume power ratio and cost of a megawatt-level and above permanent magnet direct drive wind generator.

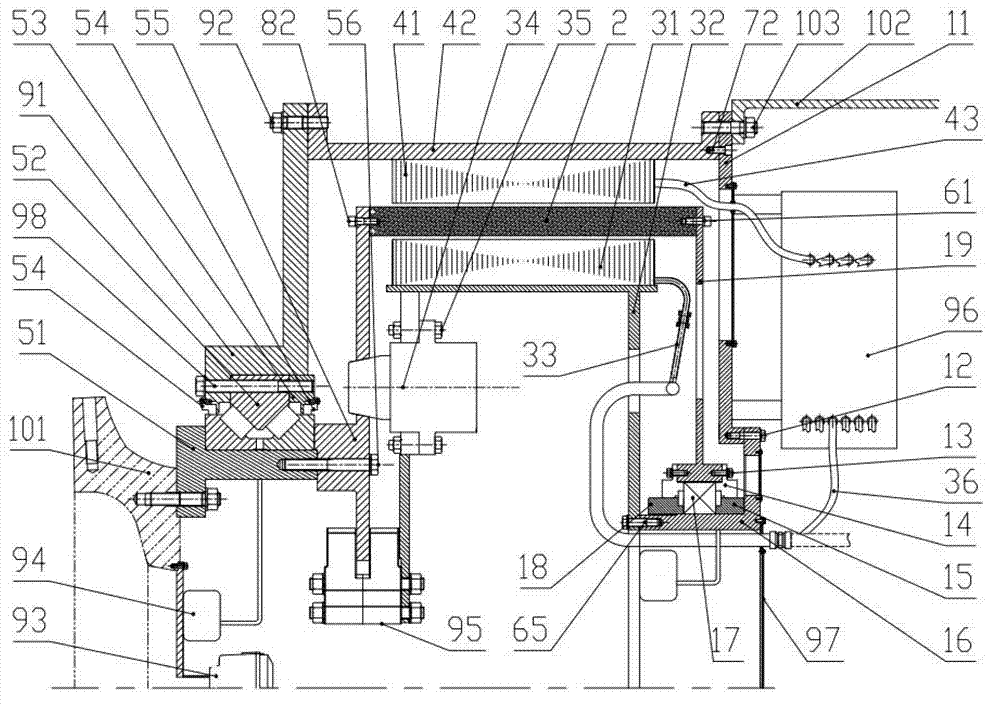

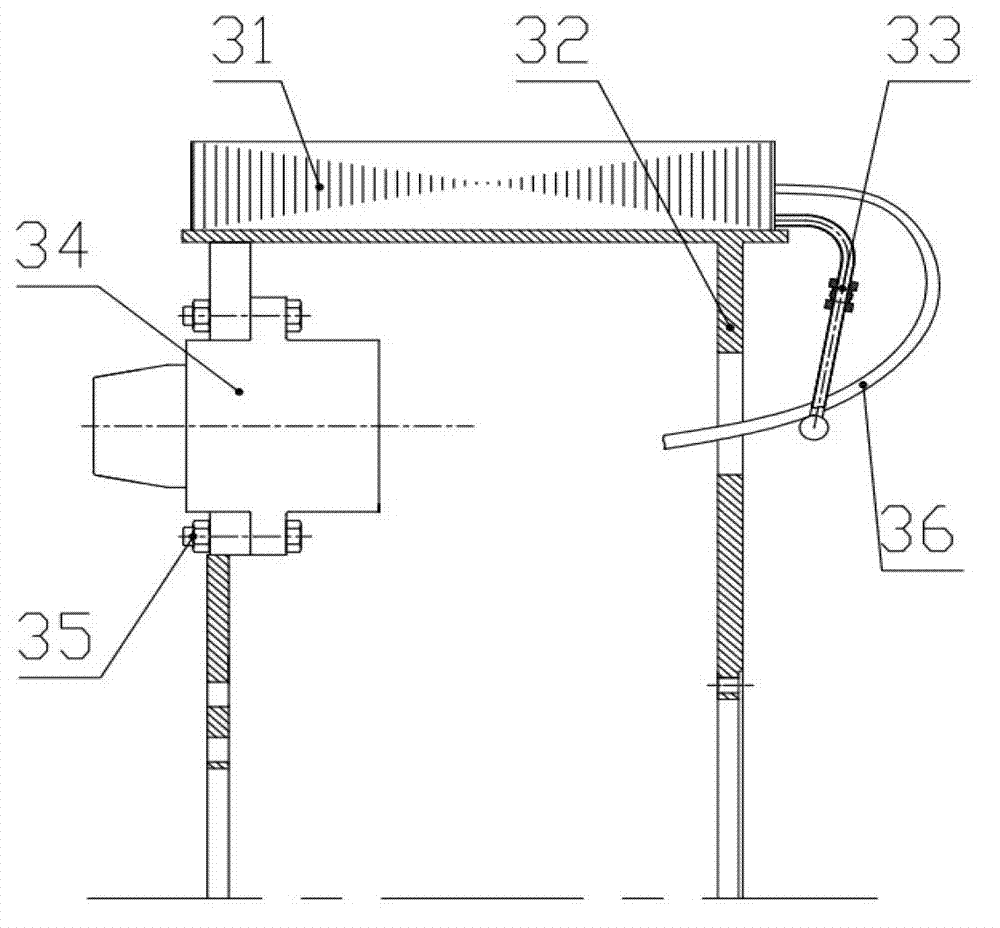

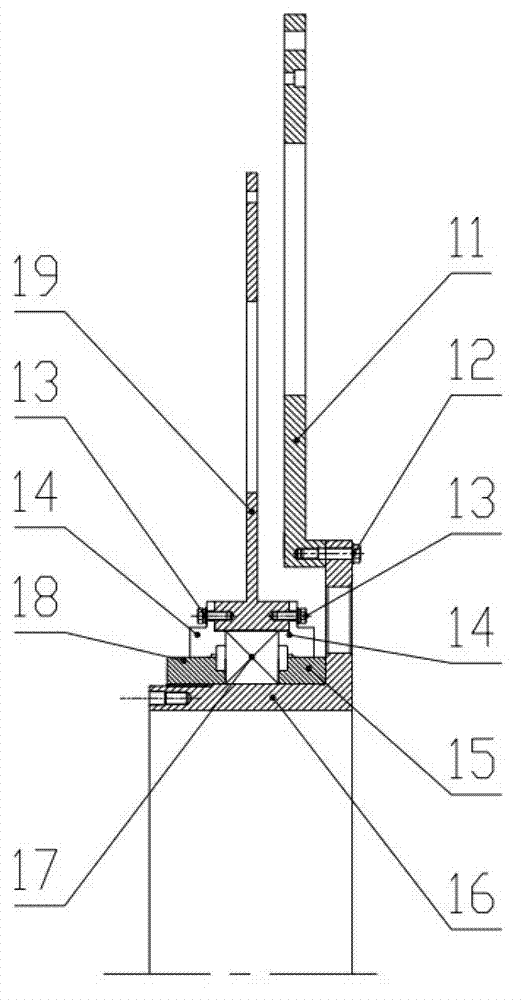

[0039] see figure 1 As shown, the dual stator permanent magnet direct drive generator of the present invention includes a front bearing assembly, a rotor 2, an inner stator assembly 3, an outer stator assembly, a rear bearing assembly and connecting bolts.

[0040] The front bearing assembly includes a main shaft 51 fixedly connected to the hub 101 by bolts, a front bearing 52 sleeved on the main shaft 51 , and a rotor turntable 55 fastened to the main shaft 51 by hexagon head bolts 56 . Wherein, the front bearing 52 is preferably a double row tapered roller bearing, which can be provided with a front bearing rear end cover 53 and a front bearing sealing assembly 54, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com