LED (light-emitting diode) constant-current driving power supply with high power factor and wide voltage range

A voltage range, constant current drive technology, applied in the direction of electric light source, lamp circuit layout, light source, etc., can solve the problems of limited output voltage range, high manufacturing and use cost, low power factor, etc., achieve high conversion efficiency and reduce manufacturing cost. Cost and use cost, low effect required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

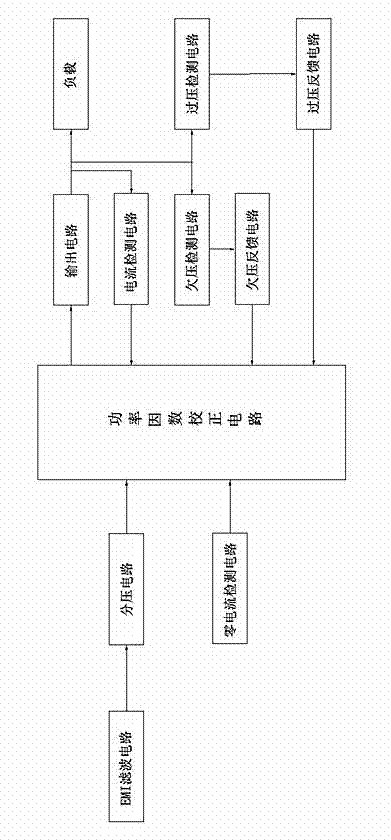

[0012] Such as figure 1 As shown: the embodiment of the present invention is provided with an EMI filter circuit, the output of the EMI filter circuit is connected to the power factor correction circuit after being divided by the voltage divider circuit, and the zero current detection circuit and the output circuit are connected to the power factor correction circuit, and the output The circuit feeds back the current signal to the power factor correction circuit through the current detection circuit, and the output circuit also feeds back the undervoltage and overvoltage signals to the power factor correction circuit.

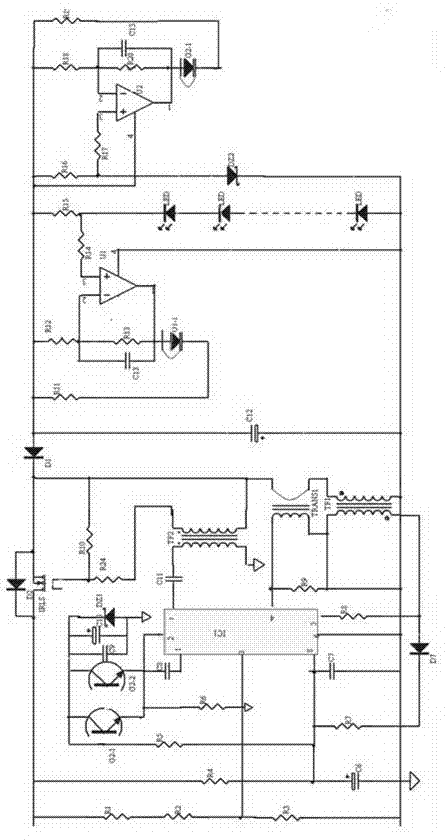

[0013] Specific lines such as figure 2 Shown: The power factor correction circuit is the power factor correction chip IC1 (Ka7526). The voltage divider circuit is composed of resistors R1, R2, R3 connected in series, the contact point of resistor R2 and resistor R3 is connected with the "3" pin of the power factor correction chip IC1, and the "7" pin of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com