CFRP-steel combined cable structure and electrochemical anti-corrosion method using rainwater to conduct electricity

A cable and steel technology, applied in the field of design and manufacture of composite cables for super-long-span suspension bridges, can solve the problems of less research and no design and construction guidelines, and achieve the effects of enhancing corrosion, increasing service life, and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

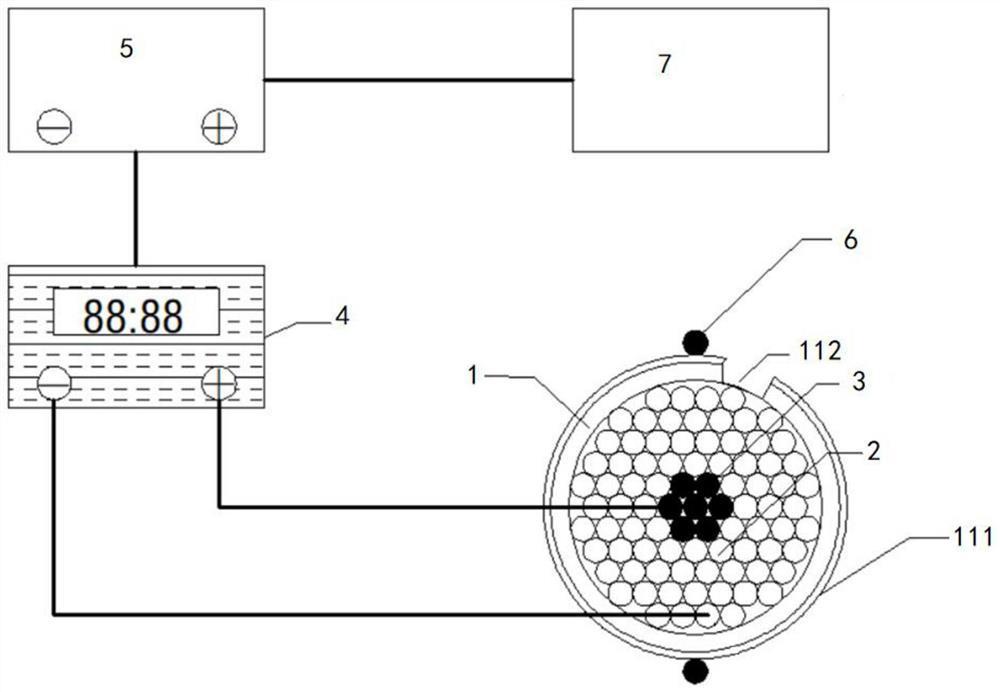

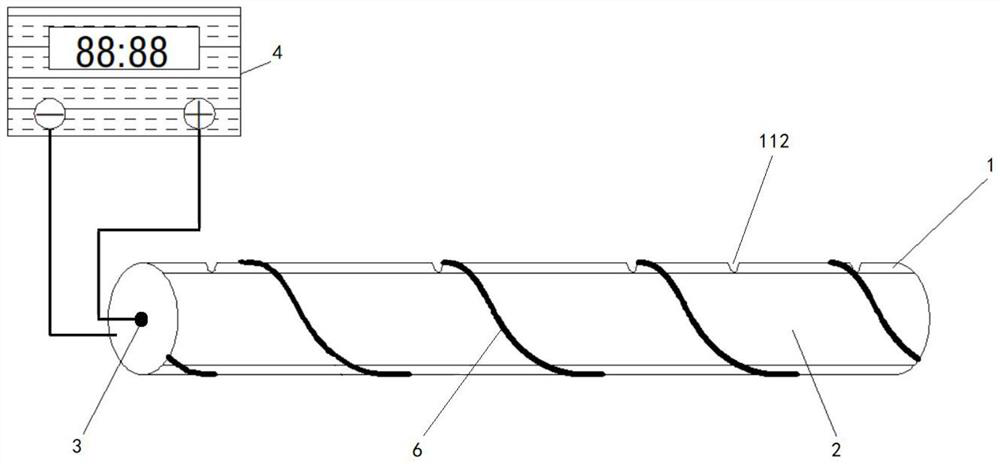

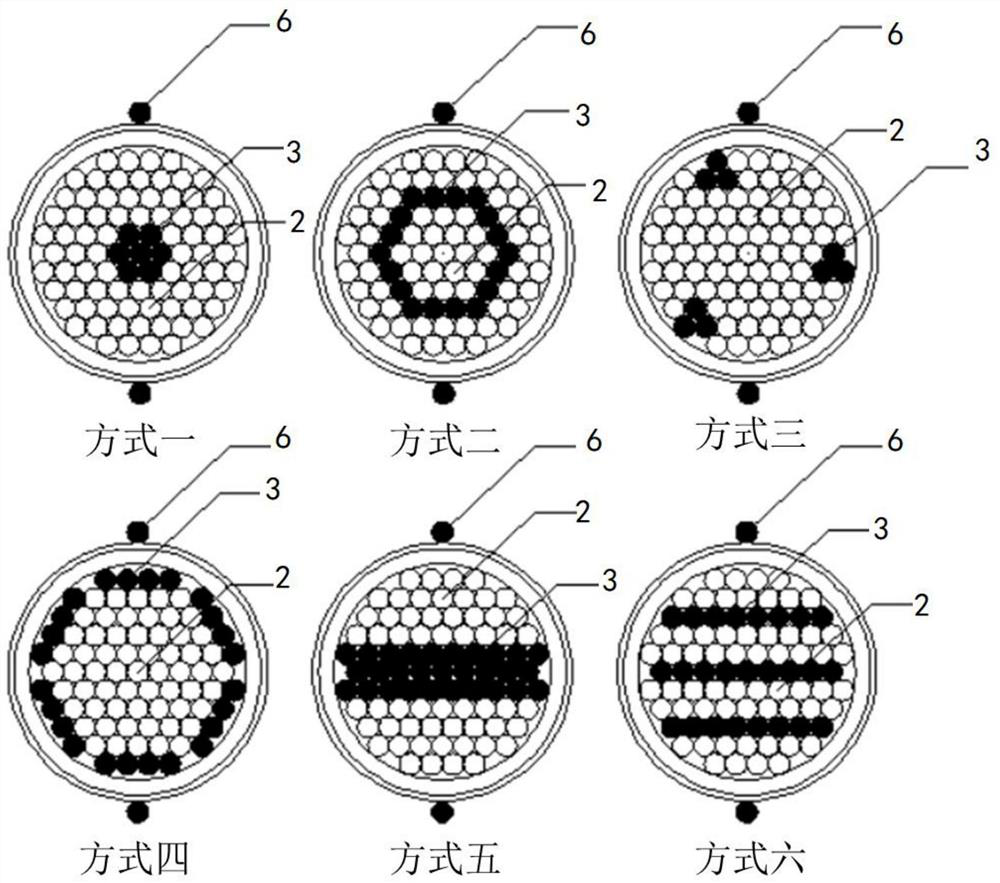

[0025] refer to Figure 1 to Figure 4 As shown, an embodiment of the CFRP-steel composite cable structure of the present invention, the cable 111 has a sheath 1, and a plurality of parallel steel wires 2 and inner CFRP strands 3 are arranged in the sheath, and the surface of the inner CFRP strands is provided with insulating and water-permeable The cladding and parallel steel wires are electrically connected to the negative pole of the rectifier, the inner CFRP strands are electrically connected to the positive pole of the rectifier, and the rectifier 4 is connected to the power supply 5 .

[0026] The above-mentioned internal CFRP strands are used as the main tensile components i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com