Full-film dual-ridge integral-straw-returning corn furrow sowing method

A full film double furrow, corn technology, applied in the field of corn sowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

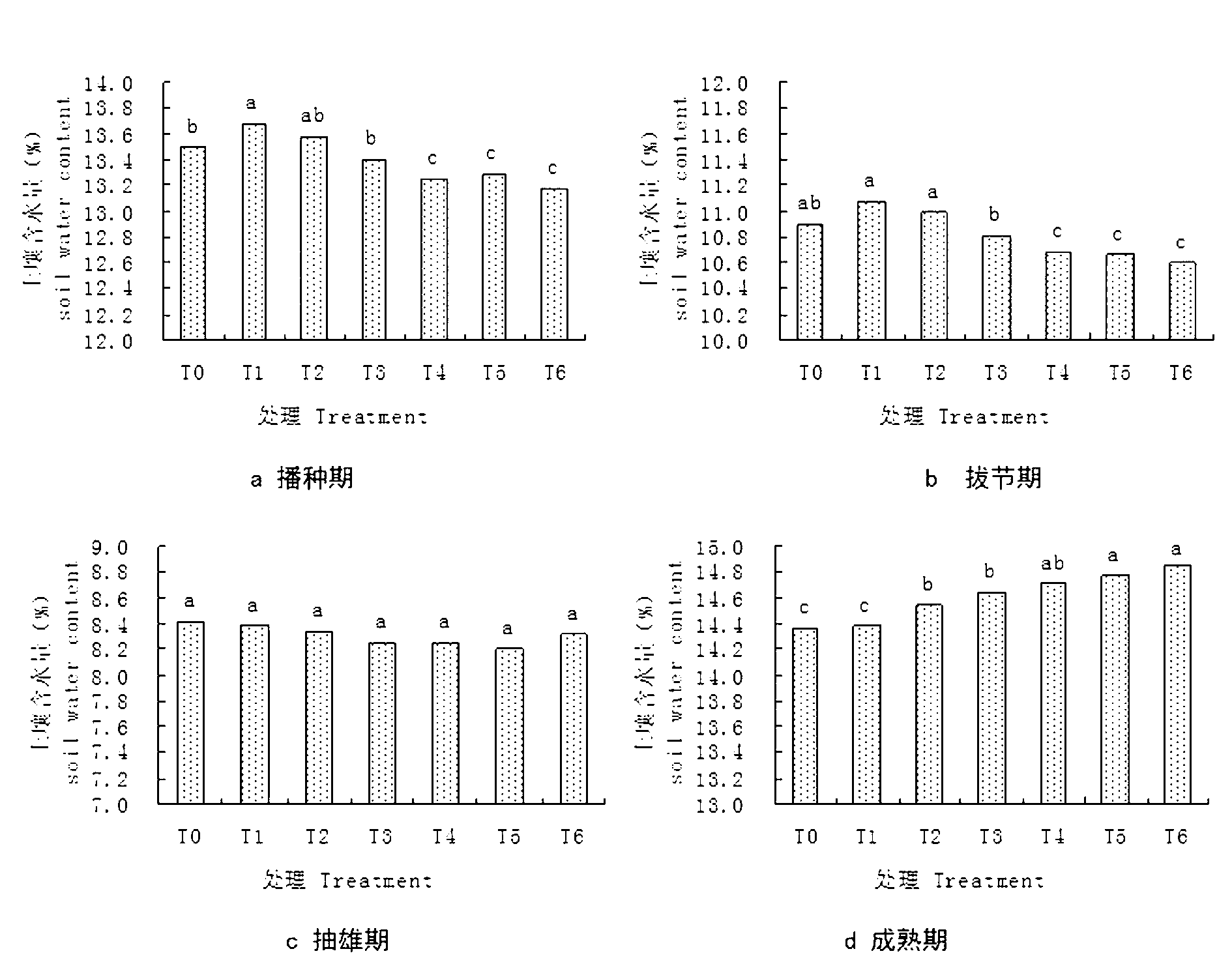

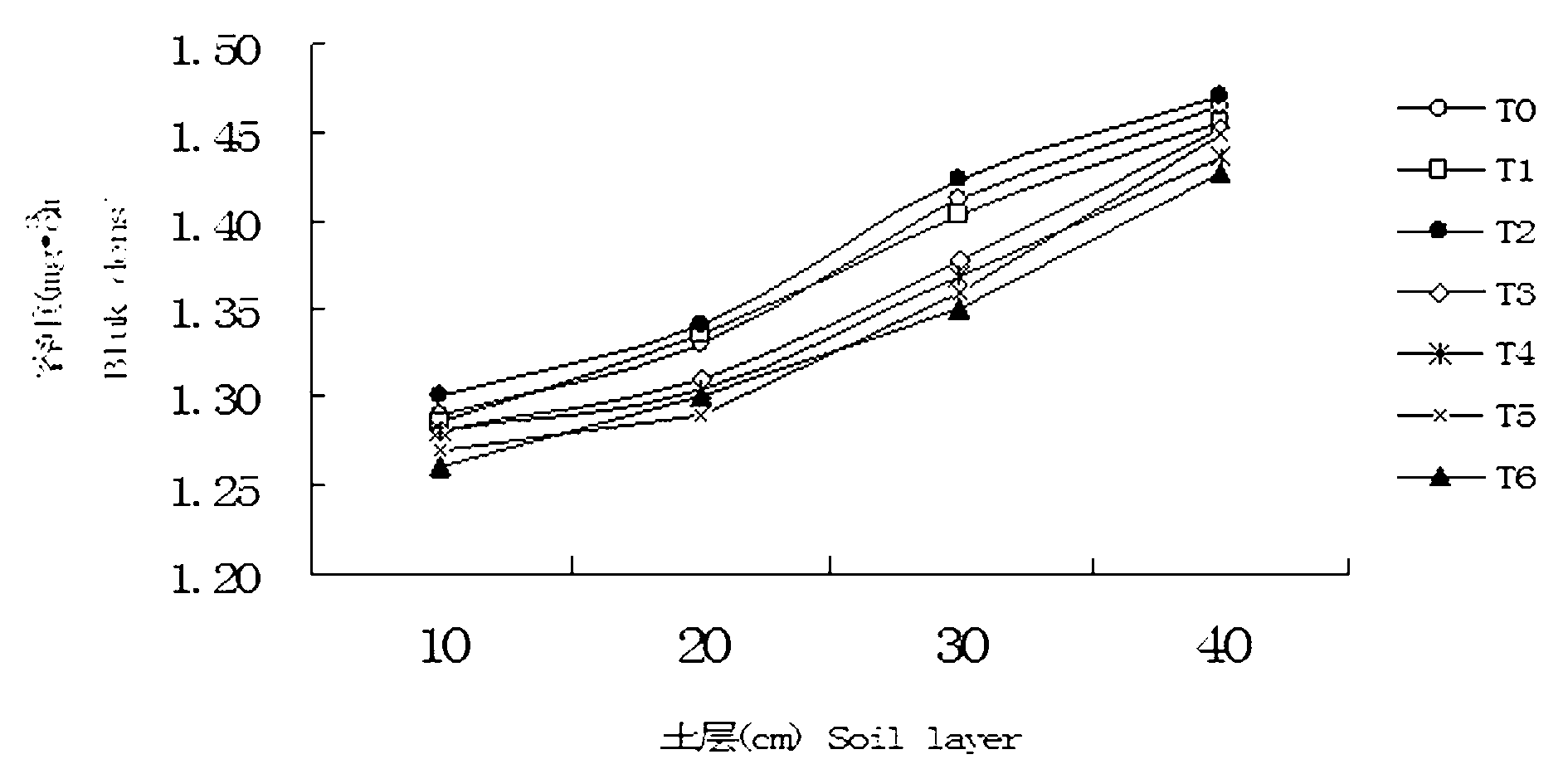

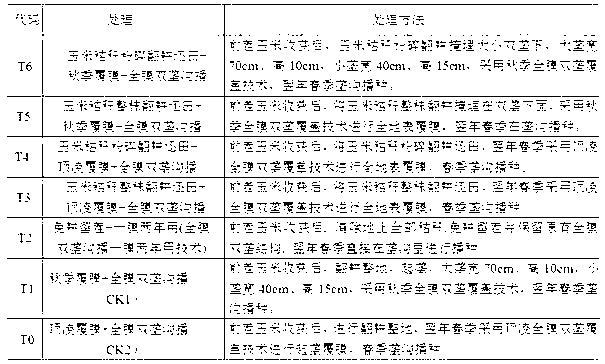

[0060] The method of returning whole stalks and whole stalks of the present invention to the furrow sowing of corn with full film and double ridges will be described in detail below through specific examples.

[0061] (1) Ridging by pressure bar: After evenly fertilizing (the fertilization rate is 40-80 kg / mu) in the inter-ridge ditch of the corn plot planted with full-film double-furrows in the previous stubble, the corn straw returning machine is used to return the corn straw to the field. The whole stalk of straw is overwhelmed in the ditch between the ridges, and shaped according to the parameters of 60-65 cm wide and 10-15 cm high to form a ridge piled up by straw;

[0062] (2) Ridging and mulching: Use the ridge-forming and mulching machine to turn over the soil at the ridge of the previous crop, and complete a 5-10 cm soil covering layer on the ridge where the straw is piled up, and finally form a width of 70-80 cm. , A ridge with a height of 15-25 cm (the ridge formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com