Four-stage type tobacco mellowing method

A tobacco leaf alcohol, four-stage technology, applied in the direction of tobacco, tobacco treatment, application, etc., can solve the problems of quality decline, environmental pollution, insufficient alcoholization of tobacco leaves, etc., and achieve the effect of prolonging the use time and ensuring the quality of alcoholization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

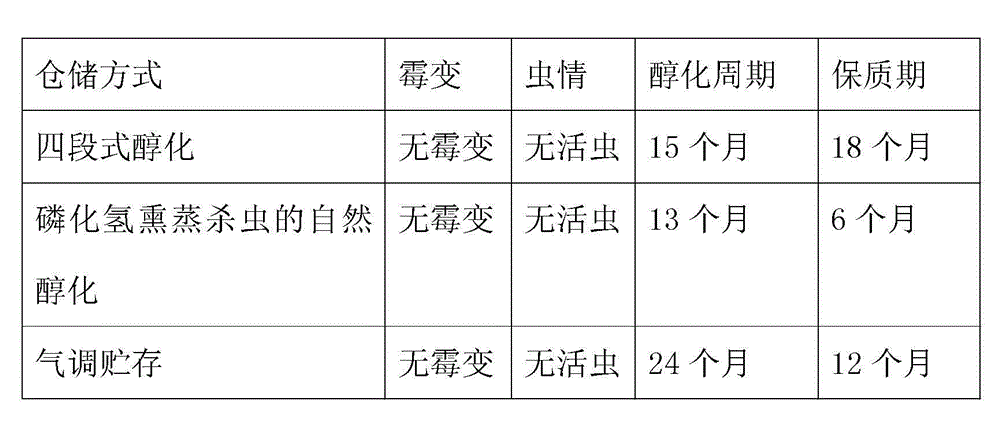

Embodiment 1

[0018] Material:

[0019] Fujian Youxi C3F-2009T 96 pieces. The test materials were equally divided into 3 parts, one part was stored by the phosphine fumigation method, one part was stored by the modified atmosphere storage method, and one part was stored by the four-stage alcoholization technology in the present invention.

[0020] Place:

[0021] Dongxiao Warehouse of Longyan Tobacco Industry Co., Ltd.

[0022] method:

[0023] 1 storage with the four-stage alcoholization technology in the present invention

[0024] The alcoholization process of tobacco leaves is divided into four stages: natural alcoholization stage, modified atmosphere anti-mold and insecticide stage, controlled atmosphere alcoholization stage and modified atmosphere preservation stage, and different alcoholization technologies are used in each stage to prevent mildew and insects in stored tobacco leaves. moth, ensure the aging quality of stored tobacco leaves, and prolong the use time of tobacco shee...

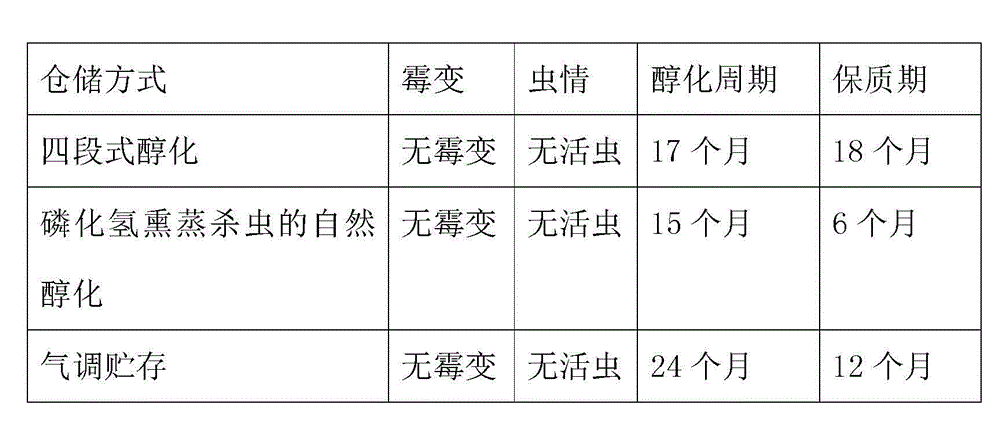

Embodiment 2

[0039] Material:

[0040] Fujian Yongding C3F-2009T 96 pieces. The test materials were equally divided into 3 parts, one part was stored by the phosphine fumigation method, one part was stored by the modified atmosphere storage method, and one part was stored by the four-stage alcoholization technology in the present invention.

[0041] Place:

[0042] Gaolin Warehouse of Xiamen Tobacco Industry Co., Ltd.

[0043] method:

[0044] 1 storage with the four-stage alcoholization technology in the present invention

[0045] The alcoholization process of tobacco leaves is divided into four stages: natural alcoholization stage, modified atmosphere anti-mold and insecticide stage, controlled atmosphere alcoholization stage and modified atmosphere preservation stage, and different alcoholization technologies are used in each stage to prevent mildew and insects in stored tobacco leaves. moth, ensure the aging quality of stored tobacco leaves, and prolong the use time of tobacco shee...

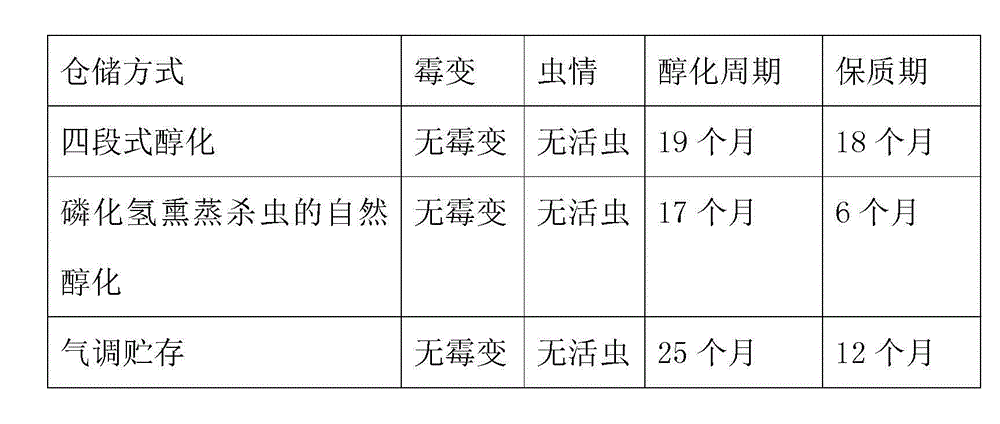

Embodiment 3

[0060] Material:

[0061] Yunnan Malong C3F-2010T 96 pieces. The test materials were equally divided into 3 parts, one part was stored by the phosphine fumigation method, one part was stored by the modified atmosphere storage method, and one part was stored by the four-stage alcoholization technology in the present invention.

[0062] Place:

[0063] Dongxiao Warehouse of Longyan Tobacco Industry Co., Ltd.

[0064] method:

[0065] 1 storage with the four-stage alcoholization technology in the present invention

[0066] The alcoholization process of tobacco leaves is divided into four stages: natural alcoholization stage, modified atmosphere anti-mold and insecticide stage, controlled atmosphere alcoholization stage and modified atmosphere preservation stage, and different alcoholization technologies are used in each stage to prevent mildew and insects in stored tobacco leaves. moth, ensure the aging quality of stored tobacco leaves, and prolong the use time of tobacco she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com