Press machine device for bending deformed steel bar in shape of Chinese character 'ji'

A rebar and zigzag technology is applied in the field of moulds of zigzag concrete embedded parts for bending rebars of presses, which can solve the problems of large error in external dimensions, low efficiency, easy deformation, etc., and achieves good forming, high work efficiency and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

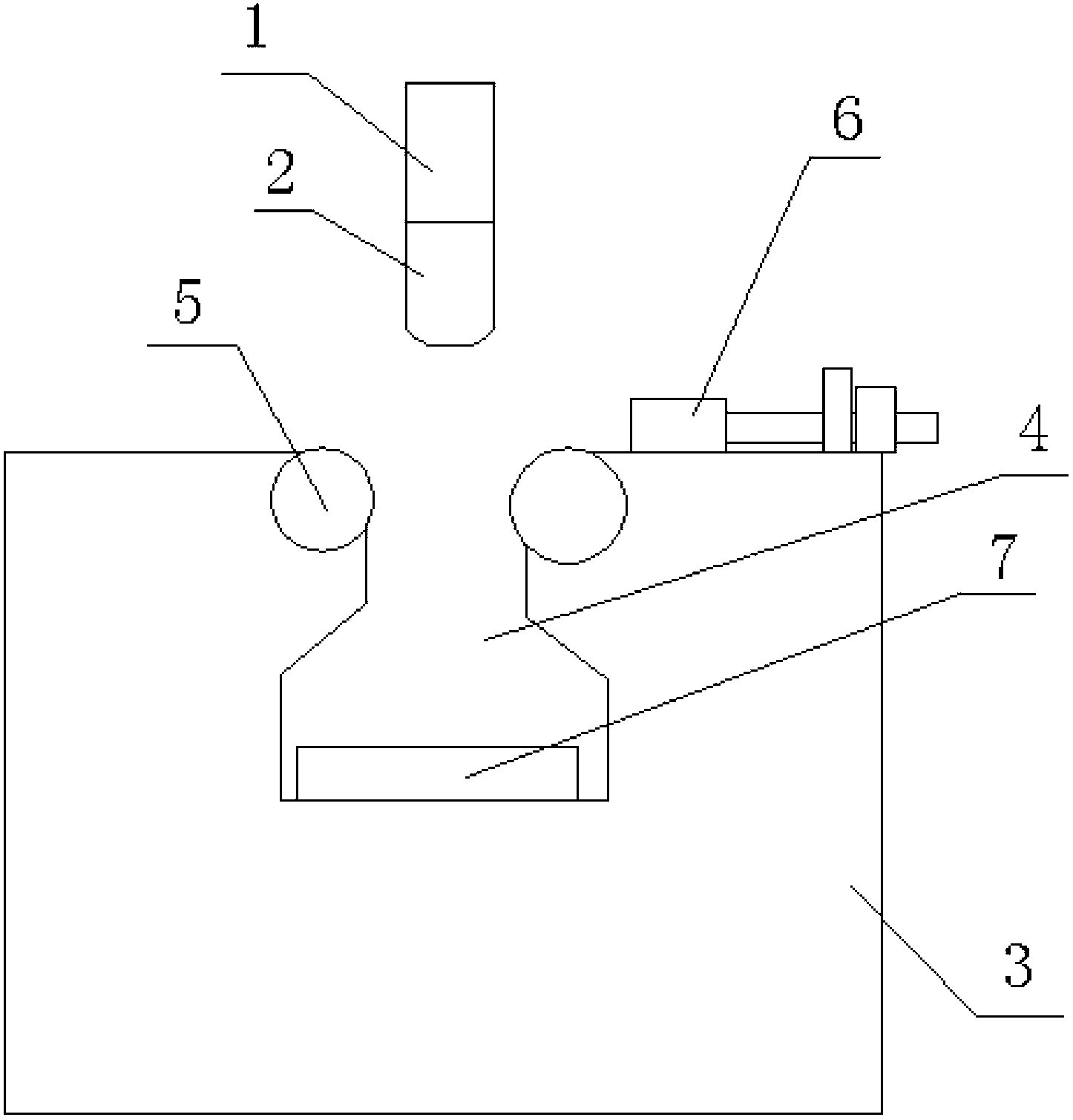

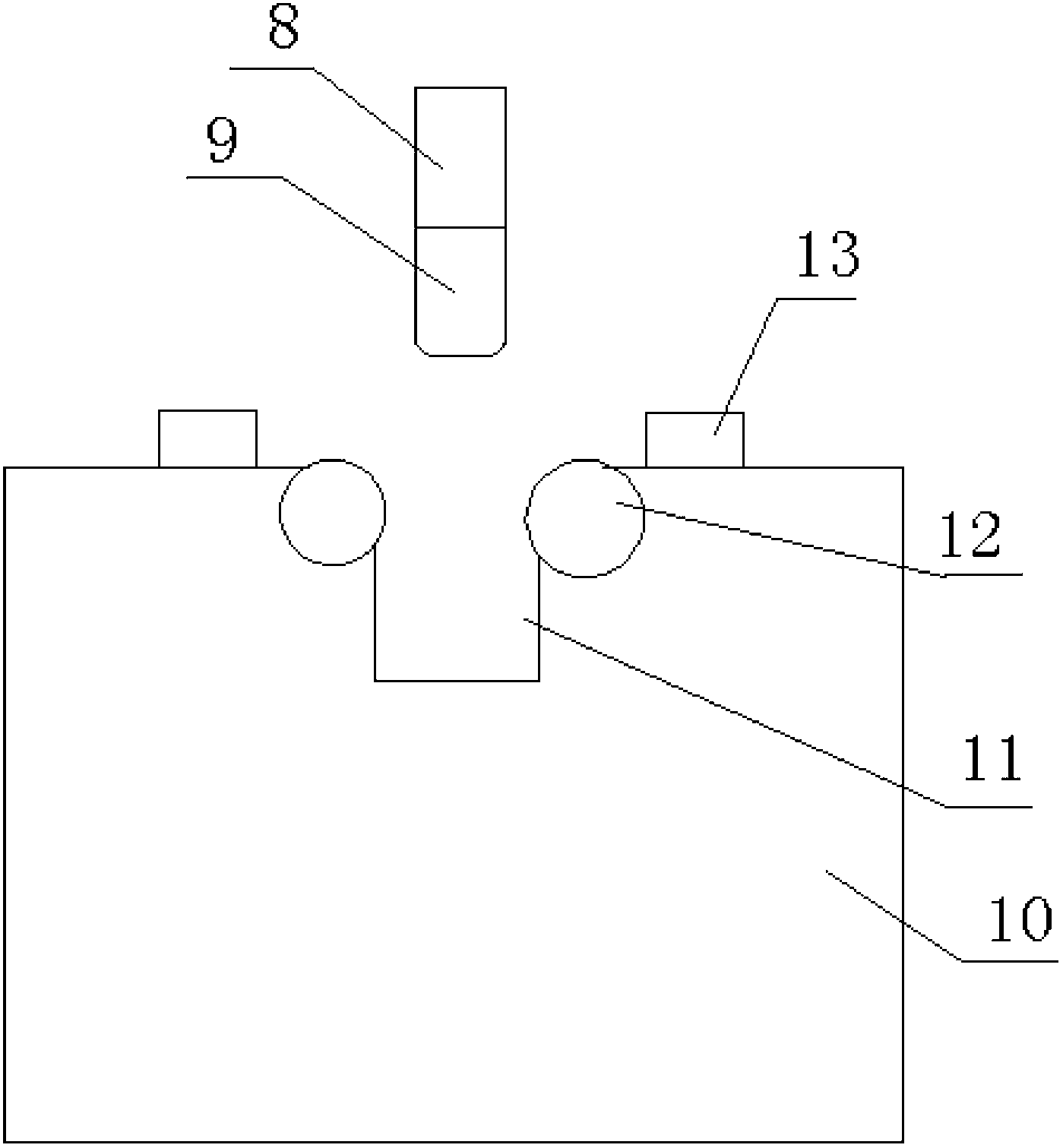

[0014] A device for bending a few-shaped rebar for a press in this embodiment is as follows: figure 1 As shown, the several-shaped rebar is used for concrete embedded parts, including the first processing mold and the second processing mold, the first processing mold includes a first upper mold and a first lower mold, and the first The upper mold is set opposite to the first lower mold; the first upper mold includes a first upper mold body, and the first upper mold body is provided with a first U-shaped punch with an inner card shape and a straight fillet belt, The upper end of the first punch is parallel to the lower end, and the outer side of the first punch is provided with a first upper mold arc groove with the same diameter as the round steel to be bent; the first lower mold includes a first lower mold Body, the first lower die body is provided with a first U-shaped support frame matched with the first punch, and the two open ends of the first U-shaped support frame are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com